In the world of machinery and mechanical systems, precision is key. Spline shafts play a crucial role in ensuring that precision, serving as integral components in power transmission and motion control. However, not all spline shafts are created equal, and choosing the right one for your specific application can be a complex task.

Understanding Spline Shafts

Before delving into the selection process, it’s important to have a clear understanding of what spline shafts are and how they function.

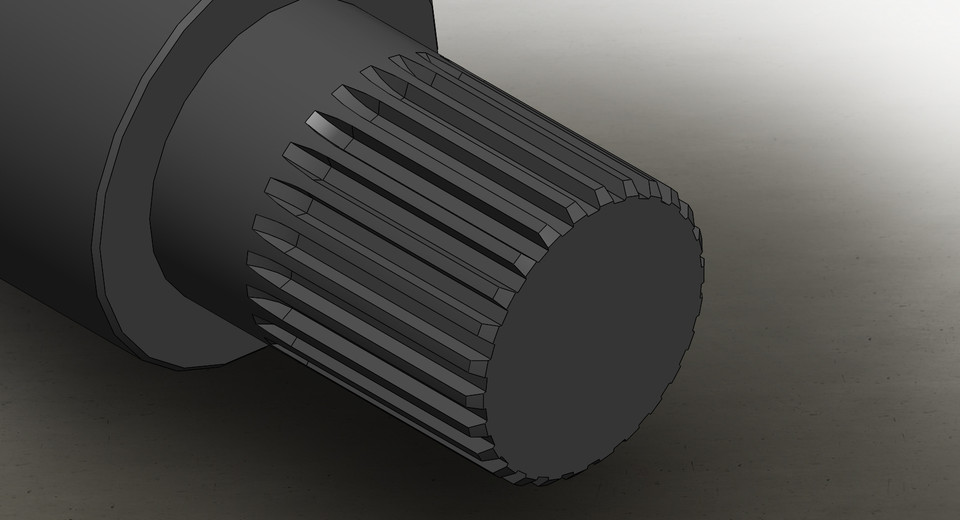

A spline shaft is a mechanical component with ridges or grooves (spline teeth) that mesh with a corresponding component, typically a mating spline bore. This design allows for the transmission of torque while permitting axial movement. Spline shafts are commonly used in applications where precision, reliability, and smooth motion are essential.

Key Considerations in Choosing a Spline Shaft

- Spline Type: Spline shafts come in various types, including involute splines, straight-sided splines, and serrated splines, each with unique tooth profiles. The choice of spline type depends on factors such as load capacity, torque requirements, and application-specific needs.

- Material: The material of the spline shaft affects its durability and performance. Common materials include steel, stainless steel, and aluminum. Consider factors like corrosion resistance, temperature tolerance, and the application’s environment when selecting the material.

- Tooth Profile: The tooth profile of the spline shaft can significantly impact its performance. Involute splines offer smooth power transmission and are commonly used in high-torque applications. Straight-sided splines are easier to manufacture and may be suitable for lighter loads.

- Tolerance and Fit: Ensure that the spline shaft’s tolerances match the mating component. Proper fit is essential for the efficient transfer of power and torque.

- Length and Diameter: Consider the length and diameter of the spline shaft in relation to your application’s requirements. Oversized or undersized shafts can lead to inefficiencies or compatibility issues.

- Load Capacity: Determine the expected load capacity of the spline shaft. This includes both axial and radial loads. Different spline designs are better suited to handle various load types.

- Environmental Conditions: Take into account the operating environment. For example, if the shaft will be exposed to moisture or chemicals, corrosion resistance is critical.

- Precision Requirements: Some applications demand extremely high levels of precision. Ensure that the spline shaft’s manufacturing and tolerances meet these requirements.

Consulting with Experts

Choosing the right spline shaft can be a complex task, especially for specialized or high-precision applications. In such cases, it’s advisable to consult with experts or engineers who specialize in power transmission components. They can provide invaluable insights and recommend the most suitable spline shaft based on your unique needs.

Selecting the right spline shaft is a critical decision that directly impacts the efficiency, reliability, and longevity of your machinery or mechanical system. By considering factors such as spline type, material, tolerance, load capacity, and environmental conditions, you can make an informed choice. When in doubt, seek guidance from experts in the field to ensure that your chosen spline shaft aligns perfectly with your application’s demands. With the right spline shaft in place, you can achieve the precision and performance your project requires.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]