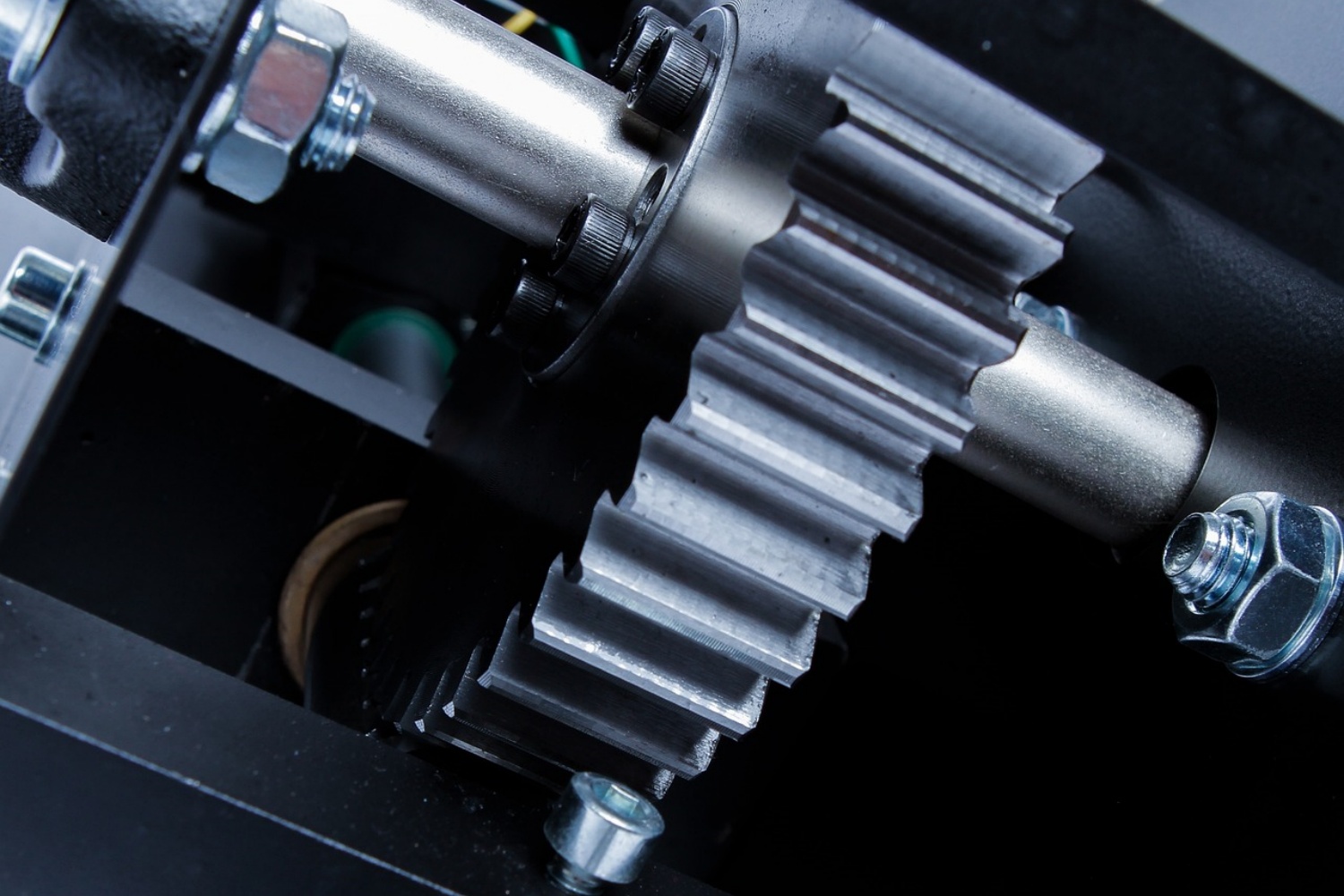

In the vast field of industrial machinery, the importance of specific components can sometimes be overshadowed by the complexities of entire systems. However, the role of a sprocket, a wheel with teeth or cogs designed to mesh with a track or chain, is central in many industrial applications, particularly in transmitting rotary motion between two shafts where gears are unsuitable. This guide delves into the specifics of casting sprockets for industrial applications, covering materials, processes, design considerations, and the impact of these components on the efficiency and longevity of machinery.

Understanding Sprockets

Sprockets are pivotal in the function of conveyor systems, automobiles, tracked vehicles, and other machinery. Unlike gears, sprockets interact with a chain or track, which is an advantage in situations where the distance between shafts is large or variable. Sprockets come in various sizes and shapes, with differences primarily in the teeth and the materials used, tailored to their specific application.

1. Materials Used in Sprocket Casting

The choice of material for casting sprockets significantly influences their performance, durability, and suitability for different environments:

- Cast Iron: Widely used due to its excellent wear resistance, ease of casting, and cost-effectiveness. It is suitable for moderate-speed applications where impact strength is not critical.

- Steel: Preferred for high-strength applications, steel sprockets offer durability and resistance to impact. Commonly used alloy steels and carbon steels provide additional benefits like heat treatability and tensile strength.

- Aluminum: Best for lightweight applications, aluminum is used where minimizing the load on the system is crucial, though it is less durable than steel or cast iron.

- Plastics and Composites: Used in low-power or precision applications. These materials are corrosion-resistant and can reduce noise, but they offer lower strength and wear resistance.

2. Casting Processes for Sprockets

Casting is a versatile manufacturing process that involves pouring molten metal into a mold where it solidifies into a specific shape. For sprockets, several casting methods are prevalent:

- Sand Casting: The most common and cost-effective method, suitable for both ferrous and non-ferrous materials. It involves pouring molten metal into a sand mold, which contains the negative shape of the desired sprocket.

- Investment Casting: Known for delivering high accuracy and good surface finish, this method is used for complex shapes and high-precision sprockets.

- Die Casting: Best for high-volume production of non-ferrous metals like aluminum or zinc. It offers a good surface finish and dimensional accuracy.

- Centrifugal Casting: This method is typically used for high-quality sprockets, where the molten metal is poured into a rotating mold, resulting in a dense and strong sprocket.

3. Design Considerations

Designing an industrial sprocket involves several critical considerations to ensure its effectiveness and longevity:

- Tooth Profile: The shape of the teeth plays a crucial role in how the sprocket interacts with the chain or track. Common profiles include the involute and the S-shaped profiles, each offering different benefits in terms of engagement and wear characteristics.

- Pitch Diameter: Determining the pitch diameter based on the size and spacing of the chain or belt ensures that the sprocket will mesh smoothly without slipping or excessive wear.

- Hub Design: The hub of the sprocket can be either split, tapered, or flanged, each providing different benefits in terms of mounting and load distribution.

- Material Thickness and Web Design: These factors affect the strength and flexibility of the sprocket. High-load applications use thicker materials and robust web designs to prevent failure.

4. Quality and Performance Testing

To ensure that sprockets meet the necessary standards and specifications, several tests are conducted:

- Hardness Testing: To gauge the resistance to wear and abrasion.

- Tensile Testing: To determine the mechanical strength of the sprocket.

- Impact Testing: Especially important for sprockets used in high-speed or high-load applications to assess their toughness.

5. Application Specifics

Depending on the application, sprockets must be tailored to withstand specific environments:

- Automotive: Requires high-strength, precision-cast sprockets to handle dynamic loads and varying operational speeds.

- Conveying Systems: Sprockets in these systems often need to be resistant to wear and corrosion, especially in harsh industrial environments.

- Agricultural Machinery: These sprockets are typically large and robust, designed to withstand dirt, mud, and the stresses of outdoor work.

The design and manufacture of sprockets are crucial for the efficiency and reliability of many types of machinery in industrial applications. Through careful selection of materials, casting methods, and design principles, manufacturers can ensure that these components meet the necessary performance standards while withstanding the rigors of industrial use. Understanding these elements allows engineers and designers to optimize their machinery for better performance, durability, and cost-effectiveness, ultimately contributing to smoother operations and increased productivity.

CONTINUE READING

Related Posts

In the intricate machinery that powers industries worldwide, sprockets play a crucial role, serving as the driving force behind rotational […]

Industrial sprockets play a pivotal role in enhancing productivity and performance across a spectrum of industrial applications. From conveying systems […]

Spline gears are essential components in mechanical engineering, widely used for their ability to transmit torque and provide precise alignment […]