Agriculture is a crucial sector that feeds the world and drives economic growth. As the demand for food increases, farmers are turning to advanced technologies to boost production and adapt to changing environmental conditions. One such technology is the customized sprocket, a precision gear that plays a significant role in various agricultural applications.

The Importance of Customized Sprockets in Agriculture

Customized sprockets have emerged as a crucial component in modern agricultural machinery, enabling farmers to efficiently transmit power and motion between mechanical components. These sprockets are designed to address specific farming needs, such as cultivating, planting, tilling, and harvesting crops. By employing precision engineering techniques and advanced materials, customized sprockets ensure reliable power transmission, improved efficiency, and extended equipment lifespan.

Functionality of Customized Sprockets in Agriculture

Customized sprockets are designed to perform specific functions based on the type of farming application. Some common agricultural sprockets include:

- Cultivating sprockets: Used for breaking up soil and removing weeds in preparation for planting.

- Planting sprockets: Designed to accurately deposit seeds at specific intervals, ensuring uniform coverage.

- Tilling sprockets: Used to loosen soil, incorporate fertilizers, and mix soil amendments.

- Harvesting sprockets: Employed in combines and other harvesting equipment to efficiently collect crops.

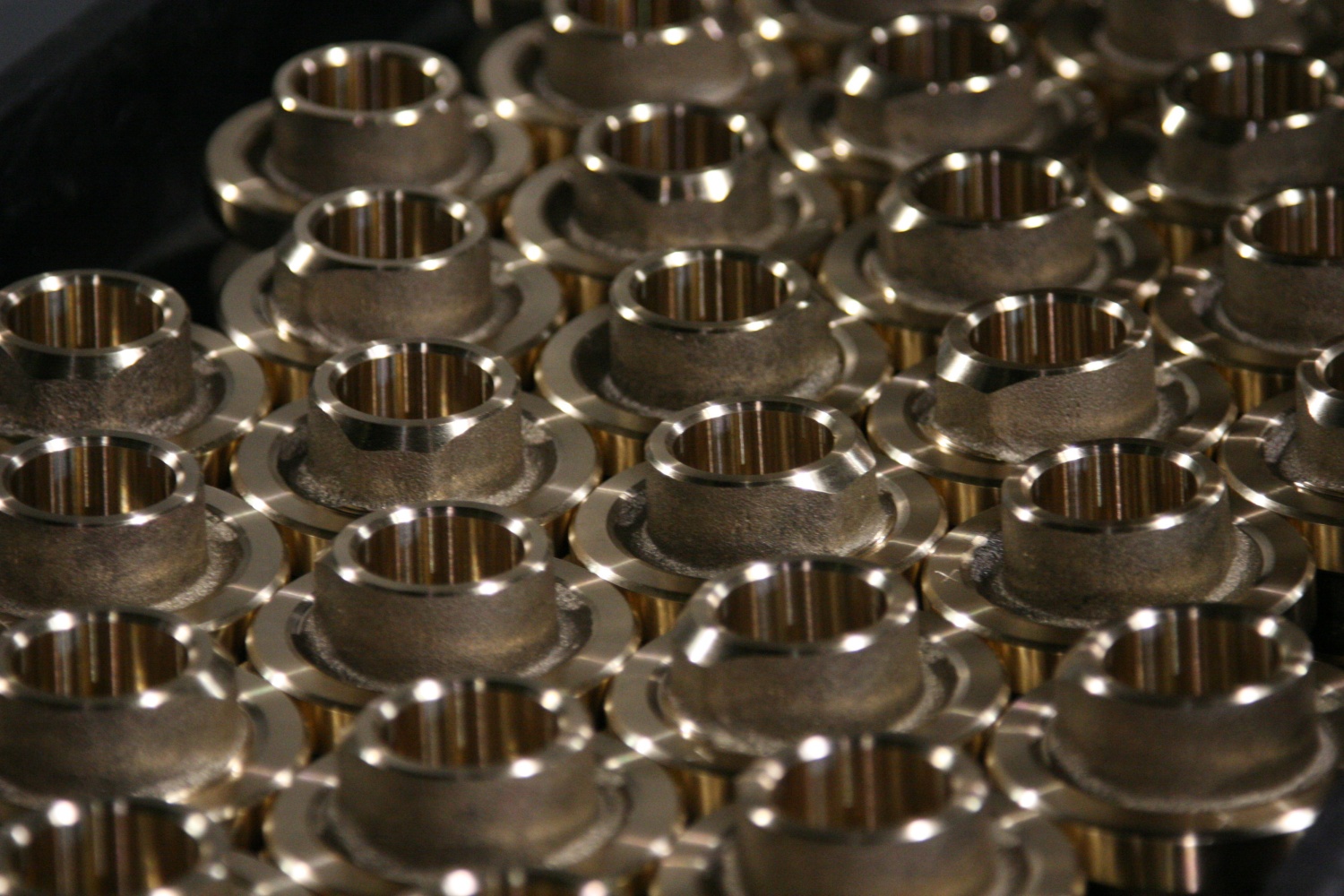

These sprockets are precision-engineered to withstand high stress and transmit torque efficiently while maintaining accurate synchronization with other components. They are typically made from high-strength materials such as steel or titanium alloys and precision-cut to exacting tolerances. The teeth of agricultural sprockets are often reinforced to increase strength and durability under heavy loads.

Precision Manufacturing Processes for Customized Sprockets

The production of customized sprockets for agricultural applications requires precision manufacturing techniques to ensure accurate dimensions, smooth surfaces, and consistent quality. The manufacturing process typically involves several steps, including material selection, heating and forming, precision-cutting of teeth, surface finishing, and quality control testing.

- Material selection: High-strength steels and titanium alloys are commonly used for their ability to withstand high stress and wear in agricultural applications.

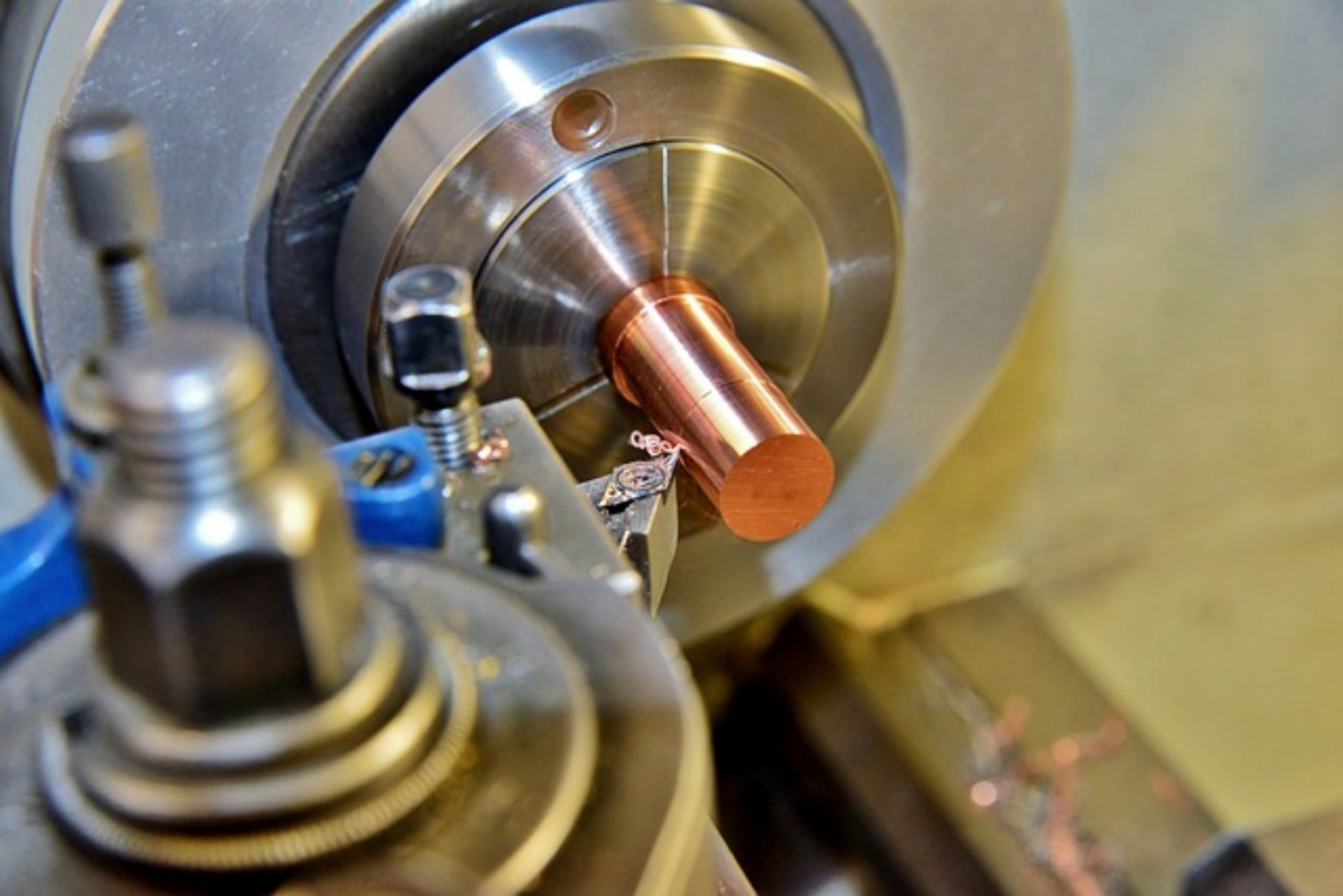

- Heating and forming: The raw material is heated to a precise temperature to soften the material and then formed into the desired sprocket geometry using dies or other forming tools.

- Precision-cutting of teeth: Advanced machining techniques such as milling or grinding are used to precisely cut the teeth into the sprocket body. This step requires precision tools and strict attention to detail to ensure accurate tooth dimensions and smooth tooth surfaces.

- Surface finishing: Polishing or coating the sprocket surface enhances its appearance, reduces friction, and improves wear resistance. This step may involve tumbling, sanding, or coating with lubricants or polymers to achieve the desired surface finish and performance characteristics.

- Quality control testing: Dimensional measurements using precision gauges or scanning electron microscopes (SEM), tensile testing to determine material strength, fatigue testing to assess durability under cyclic loading conditions, and functional testing to validate power transmission performance are essential steps in the manufacturing process to ensure the sprockets meet the required specifications and performance standards.

Adapting to Agriculture: Customized Sprockets for Diverse Farming Needs

As farmers face diverse challenges in agricultural production, customized sprockets offer adaptability and efficiency in meeting specific farming needs. For example, climate change has resulted in variable weather patterns that affect crop growth and yield. By employing precision engineering in the design of agricultural sprockets, farmers can adapt their equipment to handle these changes while maintaining optimal crop production.

Furthermore, the rise of precision agriculture encourages farmers to utilize data-driven insights to optimize农田 management practices. Customized sprockets can be designed to collect data on soil conditions, crop health, and other relevant parameters that inform farmers on how best to manage their crops. This data-driven approach helps farmers increase crop productivity while reducing inputs and environmental impact.

Additionally, as sustainable agriculture gains popularity, farmers are looking for ways to reduce their carbon footprint and minimize soil erosion. Customized sprockets can be designed with features that promote soil conservation, such as reduced tillage operations and precision planting methods. By employing these sustainable practices, farmers can maintain soil health while reducing their environmental impact.

Customized sprockets have emerged as a crucial component in modern agricultural machinery, enabling farmers to adapt to changing environmental conditions while meeting diverse farming needs. Through precision engineering and advanced material selection, these sprockets ensure reliable power transmission, improved efficiency, and extended equipment lifespan.

More: Unveiling the Benefits of Belt Pulley Manufacturing in China

CONTINUE READING

Related Posts

Copper alloys, particularly bronze, boast unique characteristics crucial for minimizing wear in gear applications, especially when paired with steel components. […]

Spur gears stand as the quintessential cog in the machinery of various industries, serving a multitude of applications with simplicity, […]

Metal machining stands as a cornerstone process in modern manufacturing, encompassing a diverse array of techniques to shape raw materials […]