Power Transmission Efficiency

Customized V-belt pulleys are essential in meeting the specific requirements of different agricultural applications. The design and manufacturing processes for these pulleys offer a high level of flexibility, enabling modifications based on specific needs. Whether it’s a tractor, harvester, or irrigation system, agricultural machinery manufacturers can rely on customized V-belt pulleys to enhance performance and efficiency.

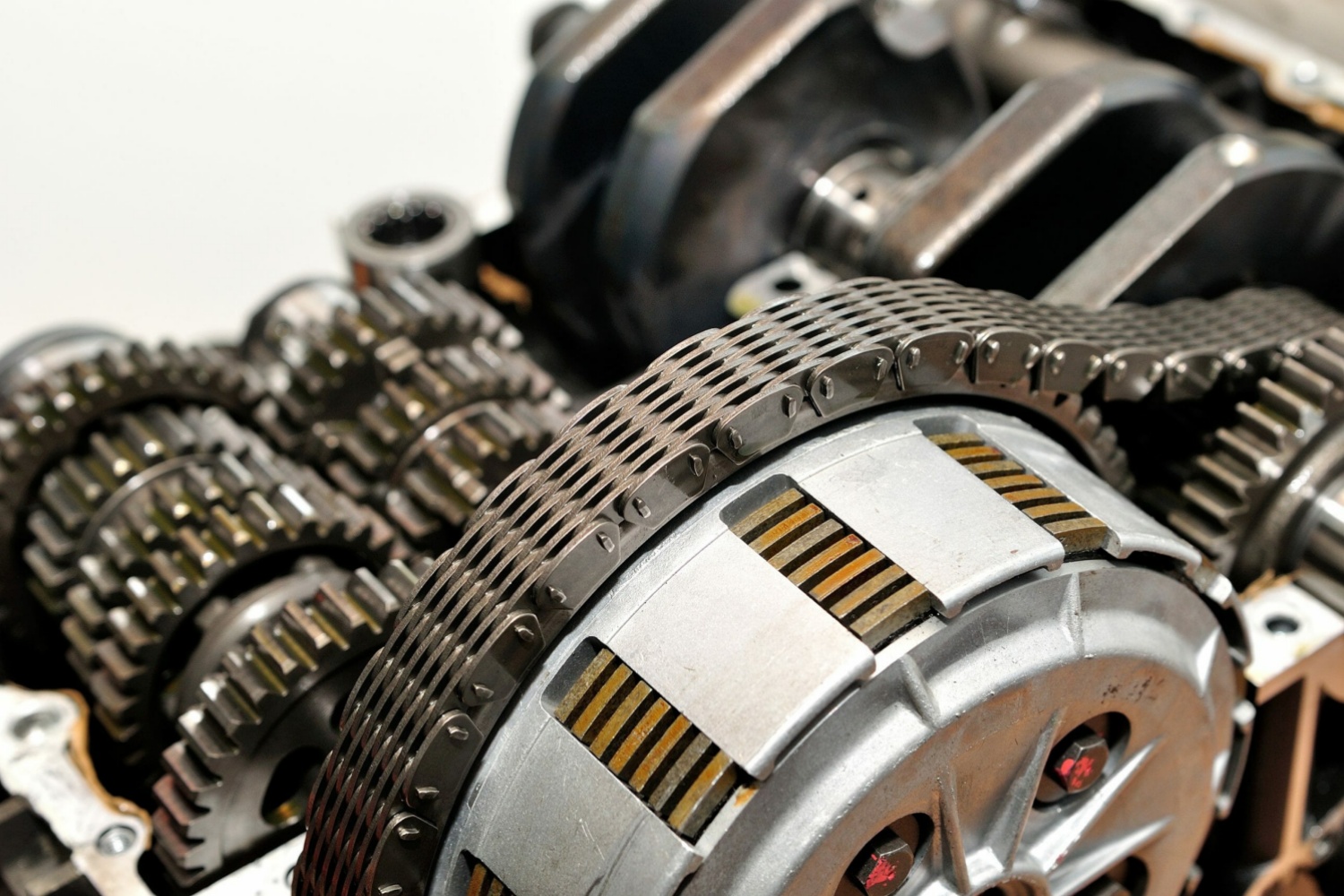

High Torque and Load Handling

One of the key advantages of using customized V-belt pulleys in agricultural machinery is their ability to handle high torque and loads. The design of these pulleys allows for maximum contact between the belt and the pulley, resulting in better torque transmission. This is particularly important in applications that require heavy lifting or propulsion, such as harvesting or tilling. By using customized V-belt pulleys, agricultural equipment manufacturers can ensure that their machines have the necessary traction and power to handle the most demanding tasks.

Improved Cooling Performance

In addition to handling high torque and loads, customized V-belt pulleys also offer improved cooling performance. The design of these pulleys allows for better airflow around the belt, which helps to keep the belt cool and minimize wear and tear. This is essential in agricultural applications, where the machinery is often operated in dusty and dirty environments that can cause rapid wear on components. By using customized V-belt pulleys with improved cooling performance, agricultural equipment manufacturers can extend the lifespan of their machines and reduce maintenance costs.

Accommodating Different Belt Sizes and Types

Another advantage of using customized V-belt pulleys in agricultural machinery is their ability to accommodate different belt sizes and types. Agricultural operations can involve a range of belts, including thick, reinforced, or specialized belts, each with its own unique properties and requirements. By using a customized V-belt pulley, equipment manufacturers can ensure a perfect fit for any belt type, resulting in efficient power transmission and reduced wear on the belt.

CONTINUE READING

Related Posts

In today’s world, industry’s need for sustainable solutions has never been greater. With growing environmental concerns and global efforts to […]

In the field of agriculture, proper equipment is essential for achieving sustainable growth. Among the various components of agricultural machinery, […]

Chain couplings, an integral part of industrial machinery, play a crucial role in ensuring the smooth transmission of power. Their […]