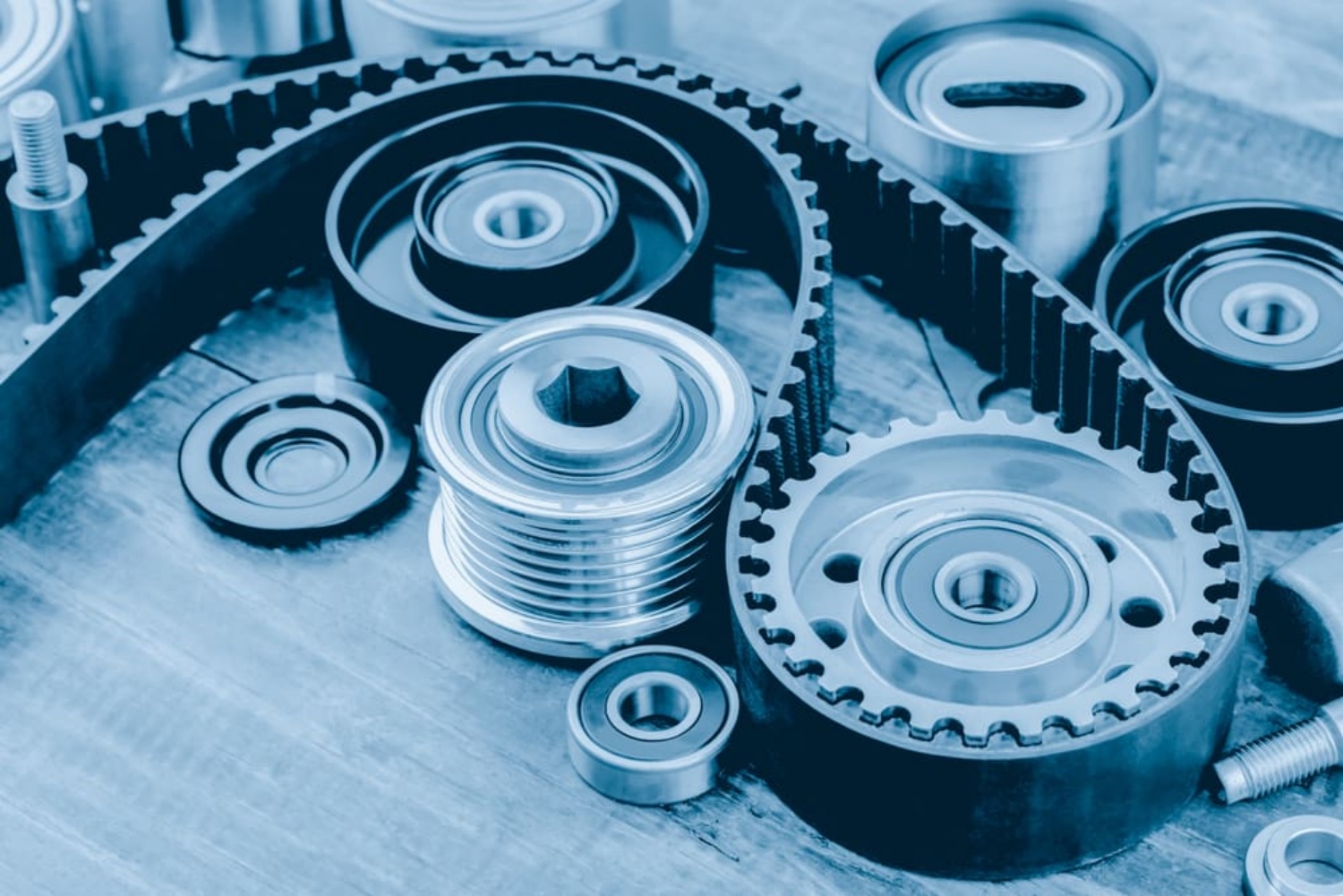

In the realm of industrial mechanics, the need for reliable and efficient transmission of mechanical power is paramount. Chain and sprocket systems stand out as a fundamental solution for translating the energy generated by motors and turbines into productive, rotating mechanical motion across various components of an industrial facility.

How Chain and Sprocket Drives Work

Chain and sprocket drives consist of a continuous assembly of chain links that mesh with toothed wheels, or sprockets. This setup is crucial for three core functions within industrial settings: transmitting power, conveying materials, and ensuring precise timing.

Diverse Applications of Chain and Sprocket Drives

- Conveyor Chain Drive: This type utilizes chains to move materials instead of traditional belts, making it ideal for industrial environments where large loads are moved rapidly and efficiently. The versatility of conveyor chain drives allows their integration into numerous types of conveyor systems.

- Hoisting and Hauling Chain Drive: Essential in material handling applications such as cranes and elevators, these drives leverage chains and sprockets to move heavy loads with high reliability and can handle significant radial forces.

- Power-Transmitting Chain Drive: Used in various machinery from cars to wind turbines, these drives transfer energy over large distances efficiently and economically, maintaining low production and maintenance costs.

Benefits of Using Chain and Sprocket Systems

Chain and sprocket drives offer distinct advantages over other mechanical transmission systems, including:

- Efficiency and Reliability: They do not suffer from slip or creep, providing a dependable power transfer mechanism that is more effective than belt drives.

- Versatility: Suitable for use in systems requiring reverse operation.

- Compact Design: These drives require less space compared to belt drives, facilitating easier installation and maintenance.

- Durability: Highly resistant to extreme temperatures and abrasive conditions, chain drives do not deteriorate from exposure to oils, greases, aging, or sunlight. They also perform well in wet conditions.

The chain and sprocket mechanism is an indispensable component in the toolkit of modern industrial systems, providing a robust, versatile, and efficient method for power transmission and material movement. For businesses looking to enhance their industrial processes with these durable systems, exploring high-quality sprockets and chains is a step towards achieving higher operational efficiency and reliability.

For quality and sturdy sprockets, consider reaching out to specialized providers who can offer a wide range of products tailored to meet the diverse needs of modern industries.

CONTINUE READING

Related Posts

In the realm of mechanical engineering and design, the terms “pulley” and “sheave” often surface, leading to a mix of […]

In the realm of industrial automation, the significance of gears and pulleys within the machinery cannot be overstated. These components […]

Industrial gears play a pivotal role in the operational efficiency and productivity of various industries. These components, often housed within […]