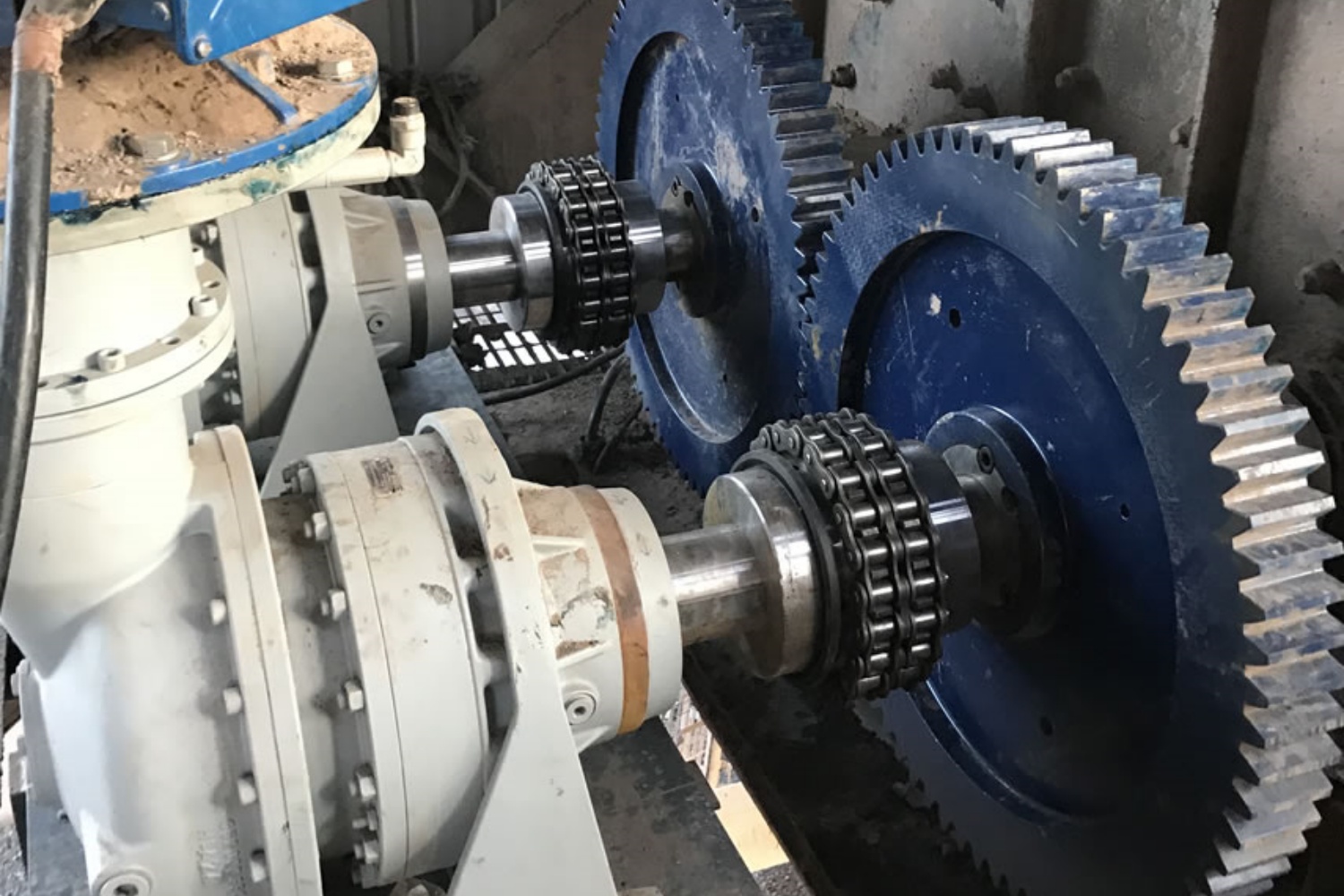

Roller chain couplings are widely employed in various industrial applications to efficiently transmit power between two shafts. Understanding their advantages is essential for selecting the appropriate coupling type for specific uses. Let’s explore the key benefits of roller chain couplings and their significance in industrial settings.

1. High Torque Transmission

Roller chain couplings excel at transmitting high torque loads between shafts with minimal power loss. The design of the roller chain enables smooth and efficient power transfer, even in high-torque applications such as heavy machinery, conveyor systems, and industrial drives. This capability ensures reliable operation and performance in demanding industrial environments, making roller chain couplings a preferred choice for high-torque requirements.

2. Misalignment Tolerance

A notable advantage of roller chain couplings is their ability to accommodate misalignment between connected shafts. Unlike rigid couplings that demand precise alignment for proper functioning, roller chain couplings can tolerate angular, parallel, and axial misalignments. This flexibility reduces the need for frequent adjustments and minimizes the risk of premature wear and failure. Consequently, equipment lifespan is extended, and maintenance costs are reduced.

3. Shock and Vibration Dampening

Roller chain couplings possess excellent shock and vibration dampening characteristics, making them ideal for applications where machinery is subjected to dynamic loads and varying operating conditions. The inherent flexibility of the roller chain allows it to absorb shocks and vibrations generated during start-up, sudden stops, or changes in load conditions. This capability protects connected equipment from damage and ensures smoother operation and enhanced reliability.

4. Easy Installation and Maintenance

Another significant advantage of roller chain couplings is their ease of installation and maintenance. These couplings typically consist of fewer components compared to other types of industrial couplings, simplifying the assembly process. Additionally, roller chain couplings require minimal lubrication and periodic maintenance, reducing downtime and maintenance costs associated with frequent servicing. This ease of installation and maintenance contributes to overall operational efficiency and productivity.

5. Cost-Effectiveness

Roller chain couplings provide a cost-effective solution for power transmission applications, particularly in industries where reliability, durability, and performance are essential. Compared to alternative coupling types such as gear couplings or elastomeric couplings, roller chain couplings often have lower initial costs and longer service lives. Their ability to withstand harsh operating conditions and transmit high torque loads efficiently makes them a cost-effective choice for many industrial applications.

Roller chain couplings offer numerous advantages that make them an attractive choice for power transmission in industrial settings. From high torque transmission and misalignment tolerance to shock absorption and cost-effectiveness, roller chain couplings provide reliable performance and durability in demanding operating environments. By understanding these advantages, engineers and maintenance professionals can make informed decisions when selecting coupling solutions for their applications, ultimately improving equipment reliability, minimizing downtime, and optimizing overall operational efficiency.

In summary, the advantages of roller chain couplings can be distilled into several key points:

- High Torque Transmission: Efficient power transfer even in high-torque applications.

- Misalignment Tolerance: Flexibility to accommodate various misalignments, reducing the need for frequent adjustments.

- Shock and Vibration Dampening: Absorbs shocks and vibrations, protecting equipment and ensuring smoother operation.

- Ease of Installation and Maintenance: Simplified assembly process with minimal lubrication and maintenance needs.

- Cost-Effectiveness: Lower initial costs and longer service lives compared to other coupling types.

These benefits underscore the versatility and practicality of roller chain couplings in a wide range of industrial applications. Whether in heavy machinery, conveyor systems, or other demanding environments, roller chain couplings provide a dependable and economical solution for efficient power transmission.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]