Cast metal refers to the metal material used for castings in casting production. It is an alloy composed of a metal element as the main component and other metals or non-metal elements are added, which is usually known as the casting alloy. The casting process of the tapered iron tapered sleeve pulley can be divided into three basic parts, namely casting metal preparation, casting mold preparation and casting processing.

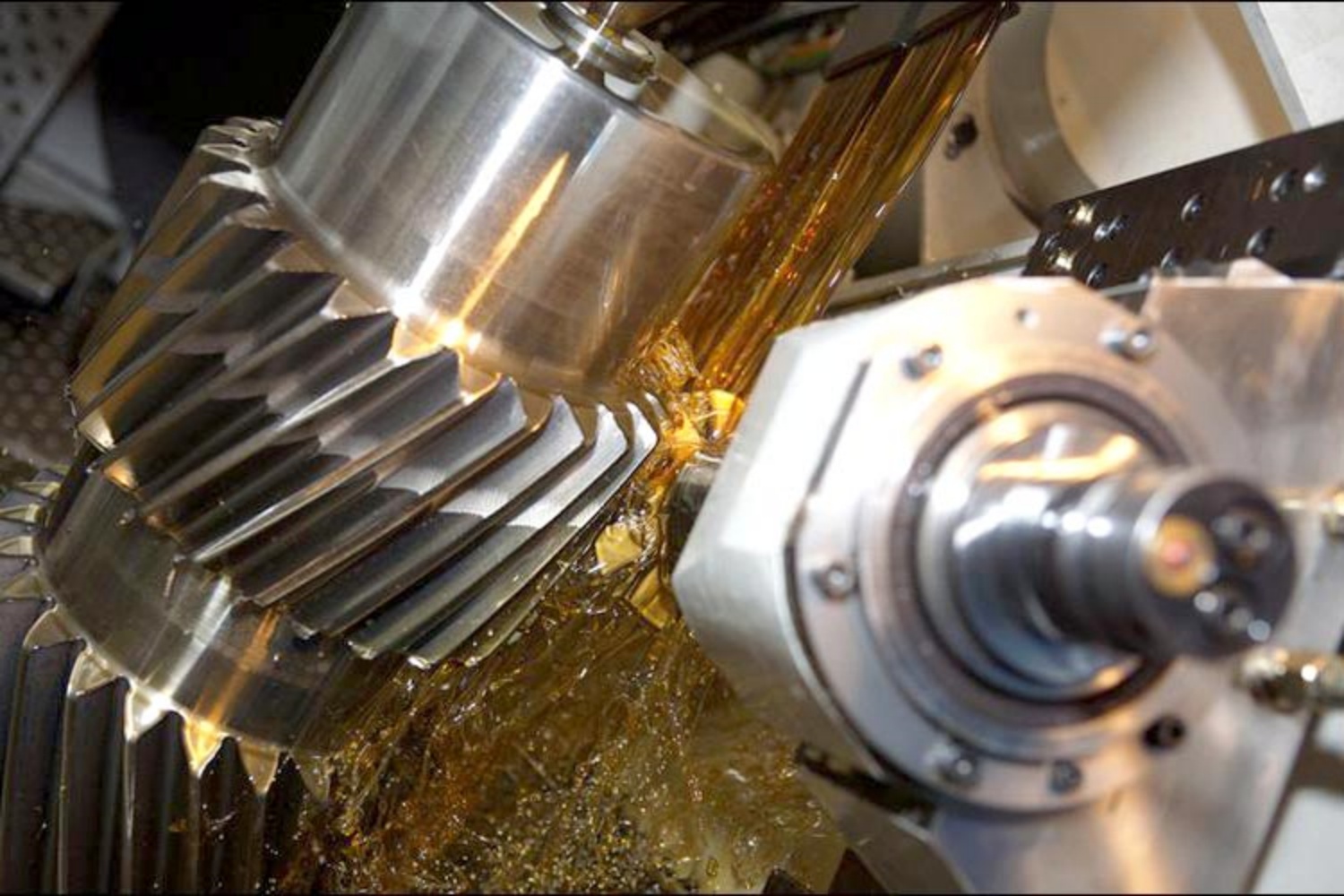

Metal smelting is not just pure melting, but also includes the smelting process, so that the metal poured into the mold meets the expected requirements in terms of temperature, chemical composition and purity. As a result, various inspection tests for the purpose of quality control are carried out during the smelting process, and the liquid metal can be poured only after reaching the specified indicators. The molten metal needs to be treated outside the furnace after it is released, such as desulfurization, vacuum degassing, refining outside the furnace, inoculation or deterioration treatment, when the requirements are more strict. Cupola, electric arc furnace, induction furnace, resistance furnace, reverberatory furnace, and others, are the commonly used equipment for smelting metal.

Diverse casting mold preparation contents will be applied based on the different casting methods. Taking the most widely used sand casting as an example, molding material preparation and molding core are the two major tasks in mild preparation. The various raw materials used in sand casting to form cores, such as foundry sand, sand binders and other auxiliary materials, as well as the moulding sand, core sand and coatings prepared from them are collectively referred to as moulding materials. The preparation is to select suitable raw sand, binder and auxiliary materials according to the requirements of the casting and the properties of the metal, and then mix them in a certain proportion into molding sand and core sand with certain properties, and the latter is specially designed for mixing chemical no-bake sands with continuous mixing and high speed.

There will be gates, risers and metal burrs after the casting is taken out from the pouring and cooling mold, and there are sands adhere to the sand-casting castings, so it must go through the cleaning process, which is normally done with the equipment, such as shot blasting machine, gate and riser cutting machine, etc. Sand casting shakeout cleaning is the first process with poor labor conditions, so it is requested to create convenient conditions for shakeout cleaning when choosing a molding method. When there are special requirements, some castings are also subjected to post-processing, such as heat treatment, shaping, anti-rust treatment, rough machining, etc.

CONTINUE READING

Related Posts

V-pulley production is a crucial aspect of the power transmission industry, where reliability and durability are paramount. A well-made V-pulley […]

In today’s world, sustainability has become a key factor in manufacturing practices, with companies increasingly realizing the need to operate […]

Spline gears are an essential component of many industrial and mechanical systems, playing a crucial role in power transmission and […]