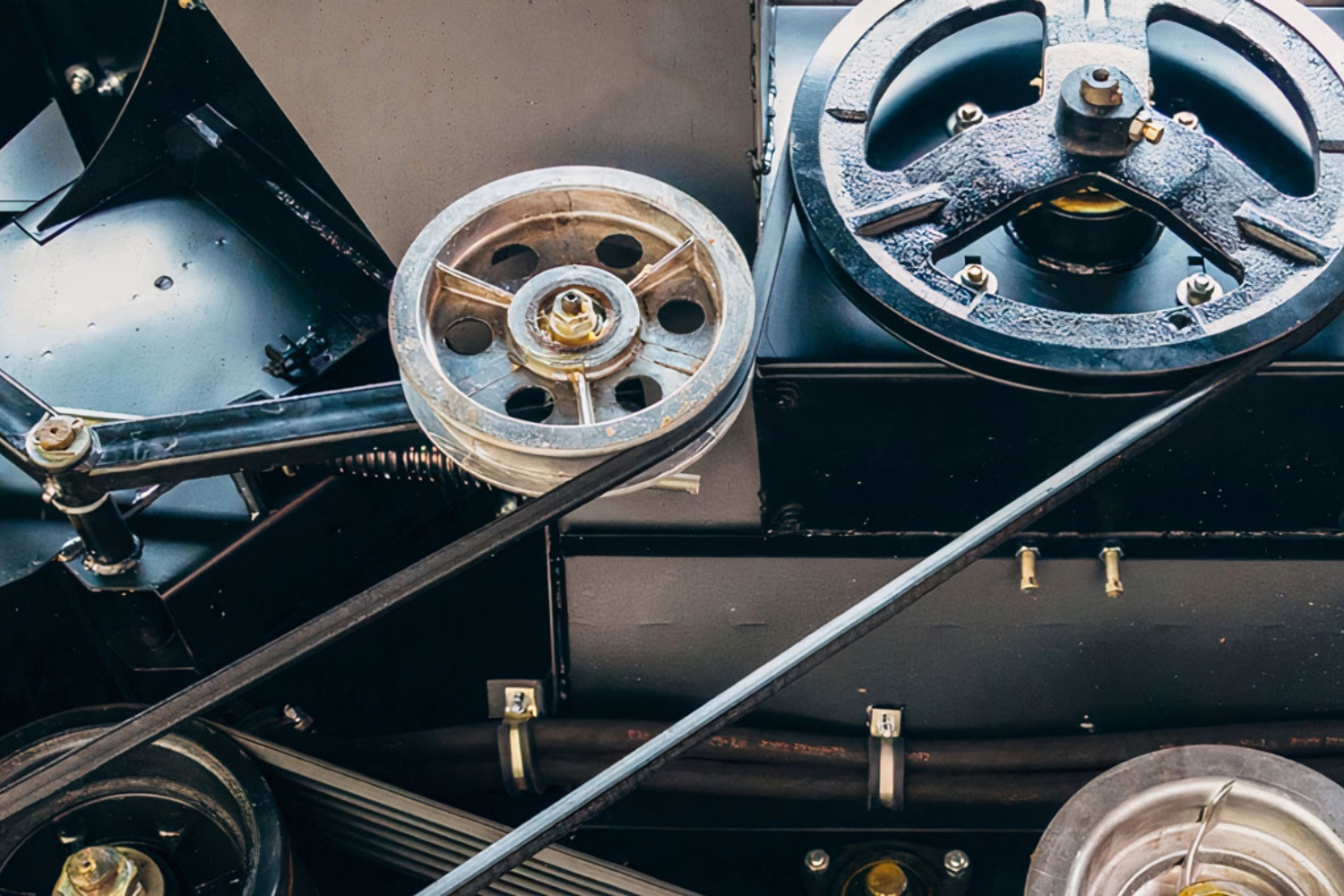

In the agricultural sector, the efficiency and reliability of machinery are paramount. V-belt pulleys play a crucial role in the operation of farm equipment, transmitting power from engines to various mechanical components. However, these belts can fail prematurely, leading to downtime and reduced productivity. Understanding the causes of V-belt pulley failure and implementing effective solutions is essential for maintaining the performance of agricultural machinery.

1. Rapid Sidewall Wear

Cause: Rapid sidewall wear in V-belts is often a sign of worn or damaged pulleys. Other factors such as exposure to extreme heat, oil, grease, moisture, and abrasive environments can also contribute to this type of wear.

Solution: Regularly inspect and replace pulleys when changing belts to ensure optimal performance. If the pulley wall appears bright and shiny, it’s time for a replacement.

2. Worn Cover on Back

Cause: Back wear usually results from the belt being forced onto the pulley or from slack within the belt causing it to vibrate against the idler during operation. Occasionally, defective or worn backside idlers can also lead to worn backside covers.

Solution: Ensure belts are correctly tensioned upon installation. Even belts designed as ‘fit and forget’ require re-tensioning within 24-48 hours of installation to maintain proper function.

3. Belt Soft and Swollen

Cause: Excessive exposure to oil or grease can cause V-belts to soften and swell, leading to improper fitting in the pulley groove. The use of belt dressing can also contribute to this issue.

Solution: Use belt guards to prevent contamination from foreign bodies, including oil and grease. Avoid belt dressings and consider using composite V-belts like Fenner PowerTwist belting, which are generally unaffected by oil, grease, water, and common industrial solvents.

4. Belt Slips and Squeals (Spin Burn)

Cause: Spin burn can result from worn or damaged pulleys, incorrect tensioning, using the wrong belt cross-section or type, excessive oil or grease, moisture, and insufficient wrap on a small pulley.

Solution: Check pulleys and belt tension, as under-tensioned belts and smooth pulleys can cause unnecessary wear. Re-tensioning the V-belt or replacing pulleys may be necessary.

5. Split Belt Cover

Cause: Forcing a belt onto a pulley or running V-belts with incorrect tension is a common cause of cover splits and other types of belt damage.

Solution: Regular belt tensioning and ensuring the correct size belts are used can help avoid this issue. Remove any foreign objects from the grooves that could cause damage.

6. Underside Cracked

Cause: Cracks typically appear on belts exposed to excessive heat, though small or misaligned pulleys and backside idlers can also cause cracking.

Solution: Consider using an EPDM rubber belt designed to withstand extreme temperatures without premature failure.

7. Missing Cogs

Cause: Missing cogs can lead to belt slippage and failure, often caused by excessive heat, too small or misaligned pulleys, or improper or prolonged storage.

Solution: Use belts designed for extreme temperatures and ensure pulleys are correctly aligned with a laser alignment tool to improve machine running.

8. Cracked Bushings

Cause: Cracked bushings indicate dangerous drive conditions, often resulting from excessive tension or the use of worn or damaged pulleys.

Solution: Avoid over-tensioning belts. Use a belt tension gauge to check and adjust tension to prevent bushing damage.

V-belt pulley failure in agricultural machinery can lead to significant downtime and reduced productivity. By understanding the common causes of failure and implementing the appropriate solutions, farmers and agricultural professionals can ensure their machinery operates efficiently and reliably. Regular maintenance, proper installation, and choosing the right belts and pulleys are key to maximizing the lifespan and performance of agricultural equipment.

CONTINUE READING

Related Posts

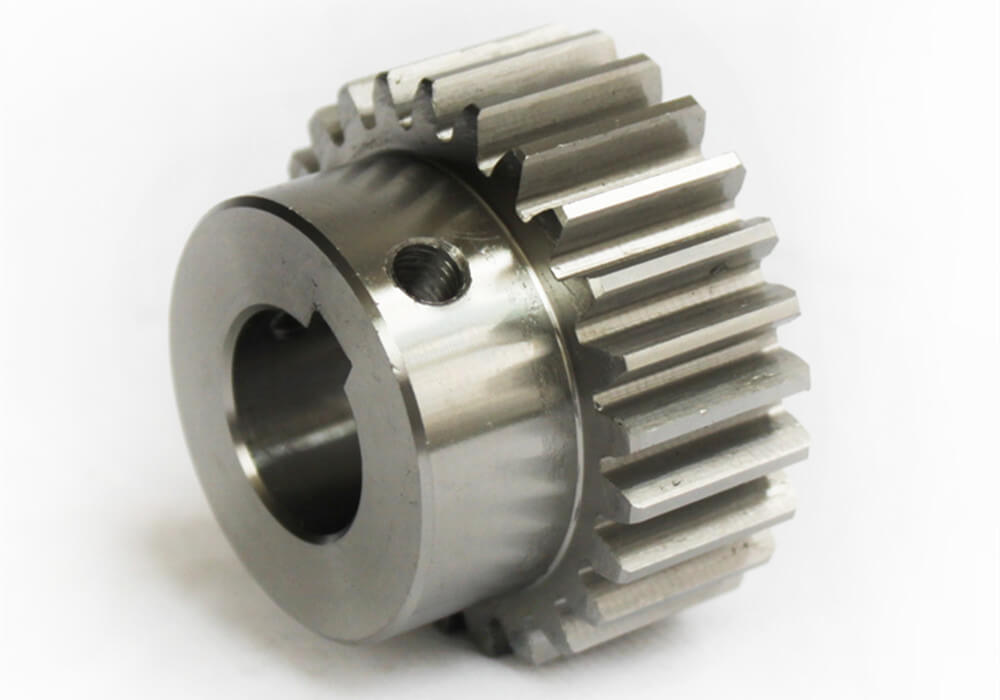

The gear structure is commonly seen in many products, which are ingenious in structure and powerful in function. However, gears […]

The materials for gears are requested with high strength, toughness and wear resistance because gears rely on their own structural […]

Although as an ‘inconspicuous’ gadget, mechanical gear will affect the operation of the entire machine if it could not function […]