Selecting the appropriate V-pulley for your application is crucial to ensure optimal performance and efficiency in power transmission systems. With various factors influencing the selection process, it’s important to consider specific criteria that align with your application requirements. This article will outline the key factors to consider when choosing a V-pulley, helping you make informed decisions that result in reliable and efficient power transmission.

Load Requirements

One of the primary considerations when selecting a V-pulley is understanding the load requirements of your application. The load can be characterized by the torque and power transmitted through the pulley. Factors such as speed, torque fluctuations, and operating conditions play a role in determining the load capacity of the pulley. It’s crucial to assess the load demands accurately to choose a V-pulley that can handle the required power transmission without compromising performance or durability.

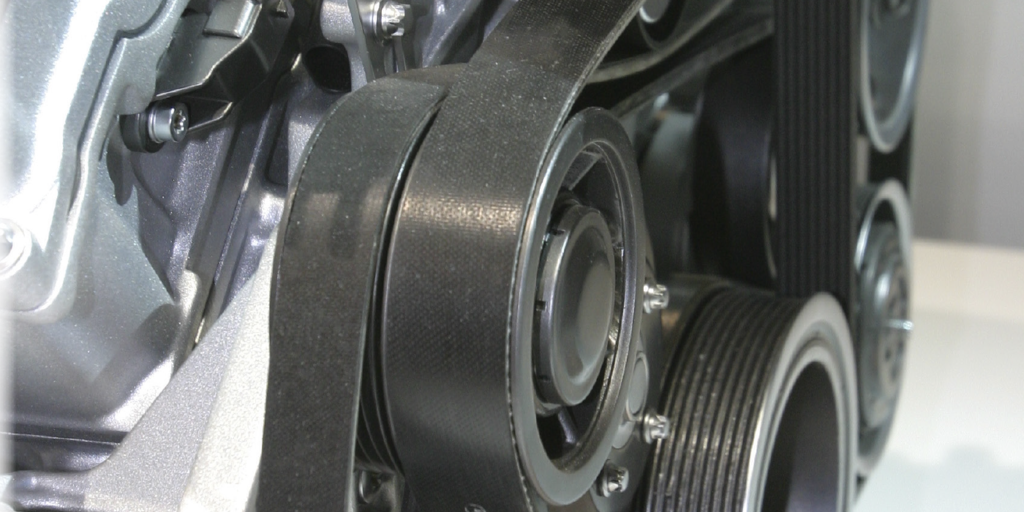

Belt Compatibility

The compatibility between the V-pulley and the belt is vital for efficient power transmission. Consider the type and size of the belt, ensuring it matches the groove profile and dimensions of the V-pulley. Factors such as belt width, thickness, and material should be evaluated to ensure proper engagement and grip between the belt and pulley. It’s essential to consult belt manufacturer specifications and guidelines to determine the appropriate V-pulley design that complements the belt characteristics.

Pulley Dimensions and Design

The dimensions and design of the V-pulley have a direct impact on its performance and efficiency. Consider the pulley’s diameter, groove profile, and number of grooves in relation to the belt size and application requirements. Smaller diameter pulleys offer higher speeds but may require increased belt tension, while larger diameter pulleys provide better belt grip and reduced belt stress. Additionally, the groove profile, such as V-shaped, flat, or round, affects belt engagement and power transmission efficiency. Choose a pulley design that maximizes belt contact area and minimizes slippage for optimal power transfer.

Material Selection

Selecting the right material for the V-pulley is essential for durability and longevity. Common materials include cast iron, steel, aluminum, and various composite materials. Consider factors such as strength, corrosion resistance, and weight when choosing the material. Cast iron is known for its strength and durability but may be heavier, while aluminum offers lightweight advantages but with reduced load capacity. Steel provides a balance of strength and weight, suitable for demanding applications. Composite materials offer advantages such as chemical resistance, reduced noise, and improved efficiency. Evaluate the specific requirements of your application and select a material that best suits the operational conditions and performance expectations.

Customization Options

In some cases, standard off-the-shelf V-pulleys may not fully meet the unique requirements of your application. Consider the availability of customization options to tailor the pulley to your specific needs. This can include modifications in dimensions, groove profiles, bore size, keyways, and surface treatments. Customized V-pulleys ensure precise fitment, optimal power transmission, and compatibility with existing equipment.

Conclusion

Choosing the right V-pulley for your application involves considering several key factors, including load requirements, belt compatibility, pulley dimensions and design, material selection, and customization options. By carefully evaluating these factors, you can ensure optimal performance, efficiency, and durability in your power transmission system. Consult with pulley manufacturers and experts, review technical specifications, and seek guidance from belt manufacturers to make informed decisions. By selecting the appropriate V-pulley, you can enhance the overall performance and reliability of your power transmission system.

CONTINUE READING

Related Posts

In the intricate dance of machinery, industrial sprockets play a pivotal role, transferring motion, torque, and power with precision. However, […]

In the intricate machinery that propels modern industries, the unassuming but critical component known as the industrial sprocket plays a […]

In the pulsating core of precision that powers industrial machinery, the intricate realm of industrial spline gears emerges as a […]