Cogged drive belts and pulleys are commonly used in power transmission applications, such as in industrial machines, automotive engines, and household appliances. The cogged drive system differs from the traditional V-belt and pulley system in the design of the belt and the pulleys, which affects their performance and applications.

In this article, we will discuss the differences between cogged drive belts and pulleys and their advantages and disadvantages.

What are cogged drive belts and pulleys?

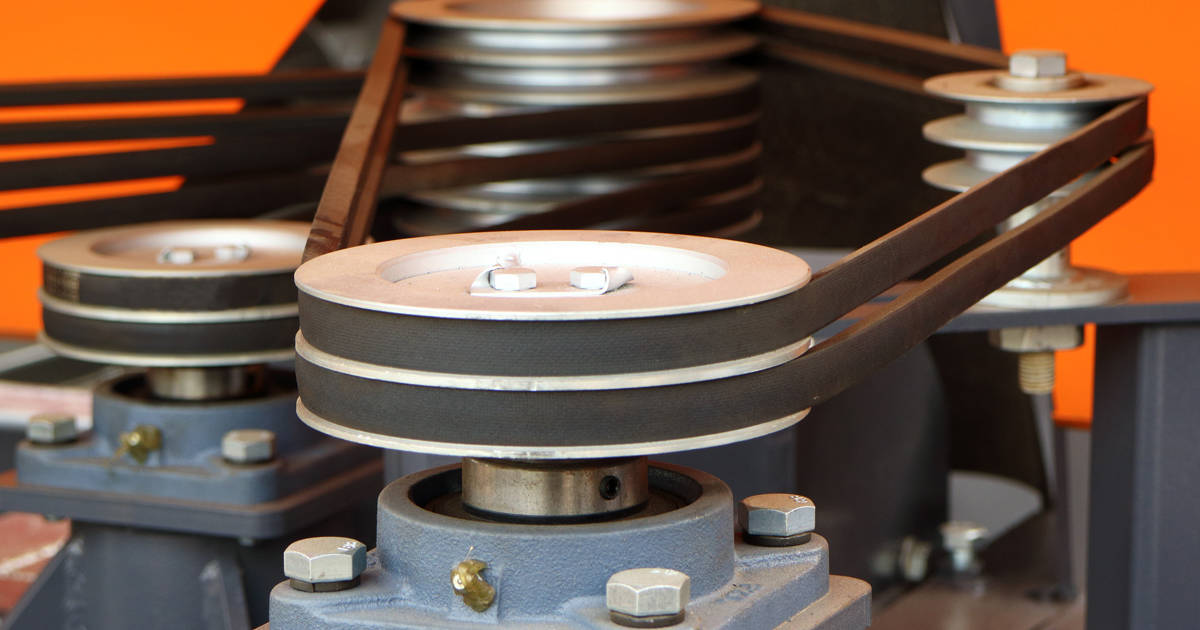

Cogged drive belts are also known as toothed or synchronous belts, due to their design of having teeth or cogs on the inner surface of the belt. The teeth mesh with grooves on the pulley, providing positive engagement and eliminating slippage. This design allows for a more precise and efficient power transfer compared to traditional V-belts.

Cogged drive pulleys have grooves that match the teeth on the belt, creating a positive engagement with the belt. The pulleys are designed to maintain accurate belt alignment and reduce the chances of the belt jumping off the pulleys.

Differences between cogged drive belts and pulleys and traditional V-belts and pulleys:

Design:

The traditional V-belt has a trapezoidal cross-section and relies on the wedging action between the sides of the belt and the pulley to transmit power. The cogged belt has teeth that engage with the grooves in the pulleys, providing positive engagement.

Power transfer:

The cogged belt and pulley system has a higher power transfer capacity than the traditional V-belt and pulley system. The positive engagement of the teeth on the belt and pulley allows for a more efficient power transfer and eliminates the slipping that can occur with V-belts.

Maintenance:

The cogged belt and pulley system requires less maintenance than the traditional V-belt and pulley system. The positive engagement of the teeth on the belt and pulley reduces wear and tear on the belt and pulley, resulting in longer life.

Noise:

The cogged belt and pulley system operates quieter than the traditional V-belt and pulley system due to the positive engagement of the teeth on the belt and pulley.

Advantages of cogged drive belts and pulleys:

Higher power transfer capacity:

The cogged drive system has a higher power transfer capacity than traditional V-belt systems due to the positive engagement of the teeth on the belt and pulley.

Efficient power transfer:

The positive engagement of the teeth on the belt and pulley allows for a more efficient power transfer, resulting in less energy loss and higher efficiency.

Longer life:

The cogged belt and pulley system requires less maintenance and has a longer service life compared to traditional V-belt systems, resulting in lower maintenance costs.

Quiet operation:

The positive engagement of the teeth on the belt and pulley results in quieter operation compared to traditional V-belt systems.

Disadvantages of cogged drive belts and pulleys:

Higher initial cost:

The cogged drive system has a higher initial cost than traditional V-belt systems.

Limited flexibility:

The teeth on the belt limit the flexibility of the system, making it less suitable for applications requiring high flexibility, such as in automotive engines.

Higher tension:

The positive engagement of the teeth on the belt and pulley requires higher tension on the belt, which can result in increased bearing and shaft wear.

Conclusion:

Cogged drive belts and pulleys offer several advantages over traditional V-belt systems, including higher power transfer capacity, efficient power transfer, longer life, and quiet operation. However, they also have some disadvantages, including higher initial cost, limited flexibility, and higher tension requirements.

The selection of the drive system depends on the application requirements, and factors

CONTINUE READING

Related Posts

In the rapidly growing food processing industry, the need for high-quality, precision equipment is more important than ever. As companies […]

In the realm of industrial machinery, gears play a pivotal role in the seamless operation of various systems. However, these […]

In the intricate dance of machinery, industrial sprockets play a pivotal role, transferring motion, torque, and power with precision. However, […]