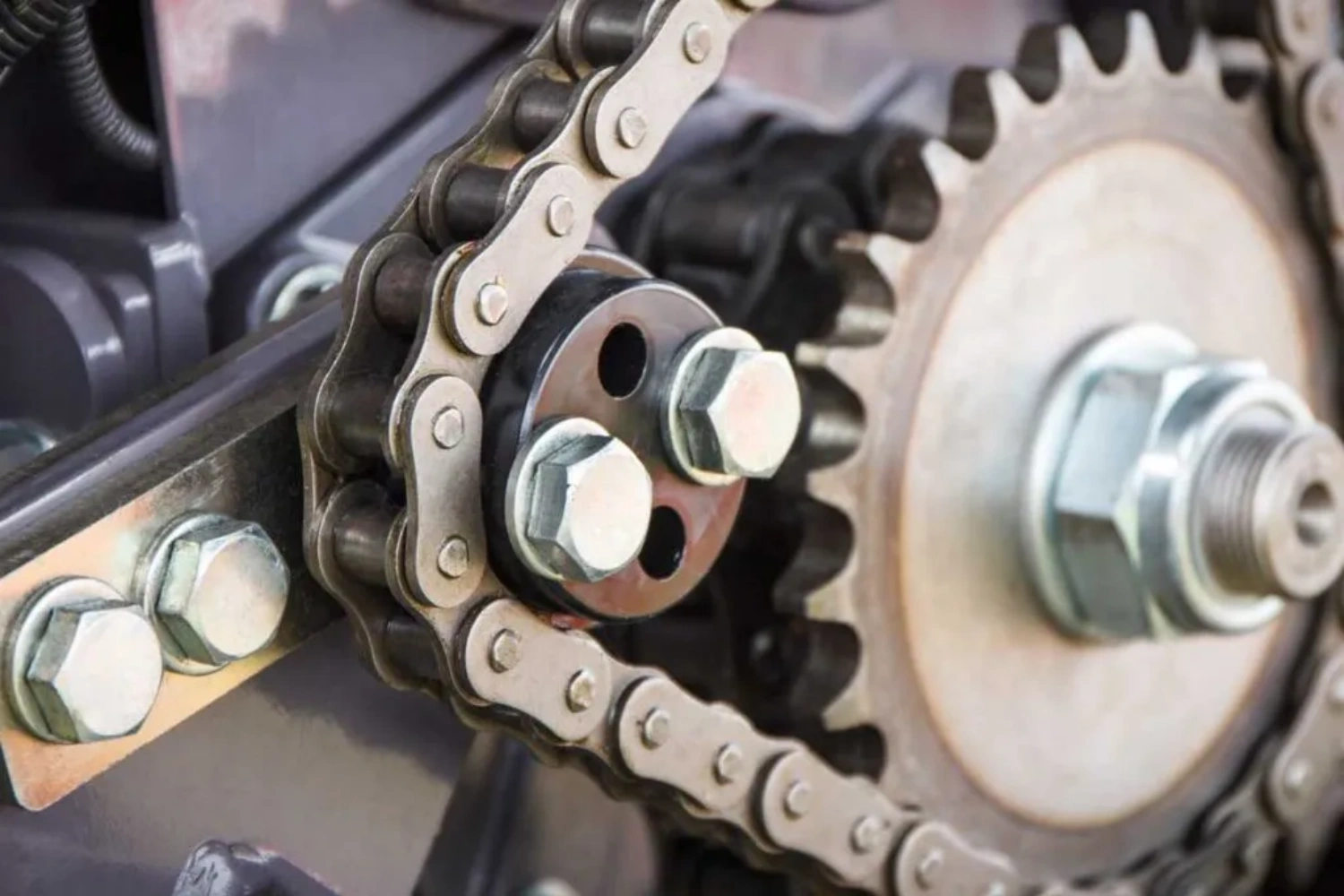

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. Whether used in conveyor systems, agricultural machinery, or heavy-duty manufacturing processes, sprockets are essential for transmitting motion and power in chain-driven systems. One of the most significant decisions for businesses is determining whether to use standard sprockets or invest in custom sprockets for their operations.

This article breaks down the key differences between custom and standard sprockets, highlighting the benefits and drawbacks of each to help you make the right choice for your machinery and operational needs.

Standard Sprockets: Affordable and Readily Available

1. Cost-Effectiveness Standard sprockets are typically more affordable than custom ones because they are mass-produced according to general specifications. This makes them readily available at lower prices, making them a common choice for businesses looking for cost-effective solutions.

2. Quick Availability One of the primary advantages of standard sprockets is their availability. Since they are produced in large quantities, standard sprockets can be quickly sourced from suppliers and installed with minimal lead time. This is ideal for operations that need quick replacements or upgrades.

3. Suitability for General Applications Standard sprockets are designed to fit common chain types and equipment. For businesses with straightforward operations where chain drives do not require highly specialized configurations, standard sprockets can perform well, ensuring smooth operation and reliable performance.

4. Consistency in Manufacturing Standard sprockets are produced under strict industry specifications, meaning they offer consistent performance and reliability. For operations that do not demand highly customized machinery, the uniformity of standard sprockets provides stability and predictability in performance.

Custom Sprockets: Tailored for Precision and Performance

1. Tailored to Your Needs Custom sprockets are specifically designed and manufactured to meet the unique requirements of your machinery and processes. They can be adjusted to accommodate unusual chain sizes, tooth configurations, and materials, which is crucial for businesses with specialized equipment or non-standard operational demands.

2. Optimized Performance When performance is a top priority, custom sprockets often deliver superior results. Their design is optimized for specific applications, allowing for precise power transmission, reduced wear and tear on chains, and improved overall efficiency. This is particularly important for high-load or high-speed systems where standard sprockets may fall short.

3. Durability and Longevity In many cases, custom sprockets are engineered from higher-quality materials or treated with specialized coatings to resist harsh environmental conditions, heavy loads, or abrasive elements. This leads to longer service life, fewer replacements, and reduced downtime, ultimately lowering the total cost of ownership.

4. Greater Flexibility in Design Unlike standard sprockets, custom sprockets allow for greater flexibility in design. This means you can specify factors such as hub diameter, tooth profile, and bore size to perfectly fit your machinery. Customization eliminates issues like chain slippage, misalignment, and uneven wear, common with improperly sized or generic sprockets.

5. Solving Complex Engineering Challenges For complex or unique industrial processes, standard sprockets often cannot meet the required technical specifications. Custom sprockets provide solutions for challenges such as tight space constraints, irregular chain configurations, or specialized motion requirements. Their precision engineering ensures that even the most intricate machinery can operate smoothly and efficiently.

Which Is Right for Your Operation?

When deciding between custom and standard sprockets, it’s important to evaluate your operational needs and long-term goals. Here are a few factors to consider:

1. Application Complexity If your machinery uses standard chains and runs in typical industrial conditions, standard sprockets may offer a perfectly adequate solution. However, if your system requires unique configurations or operates under extreme conditions (e.g., heavy loads, corrosive environments), custom sprockets will likely provide better performance and durability.

2. Budget Considerations Custom sprockets tend to have a higher upfront cost due to the design and manufacturing process. For operations with tight budgets or less critical equipment, standard sprockets can provide an affordable and effective option. On the other hand, businesses that require specialized performance may find that the investment in custom sprockets pays off over time through improved efficiency, reduced downtime, and longer service life.

3. Lead Time and Urgency If you need a quick replacement or upgrade, standard sprockets are often the better choice due to their immediate availability. Custom sprockets, by contrast, require a longer lead time for design, testing, and production, which may not be ideal for urgent repairs.

4. Long-Term Performance and Maintenance While standard sprockets offer a quick and affordable solution, custom sprockets may save you money in the long run by reducing wear, extending the lifespan of your chains, and minimizing the need for repairs. If maintenance and downtime are critical concerns, investing in custom sprockets could provide long-term operational benefits.

Both custom and standard sprockets offer distinct advantages, but the right choice depends on your specific operational requirements. Standard sprockets are an excellent option for businesses seeking quick, cost-effective solutions for general applications, while custom sprockets are ideal for those that need optimized performance, durability, and precise engineering for specialized equipment.

By carefully assessing your machinery’s needs, budget, and operational goals, you can make an informed decision that enhances both the efficiency and reliability of your power transmission systems. Whether standard or custom, sprockets are essential components in industrial operations. They play a key role in driving productivity and ensuring smooth processes.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]