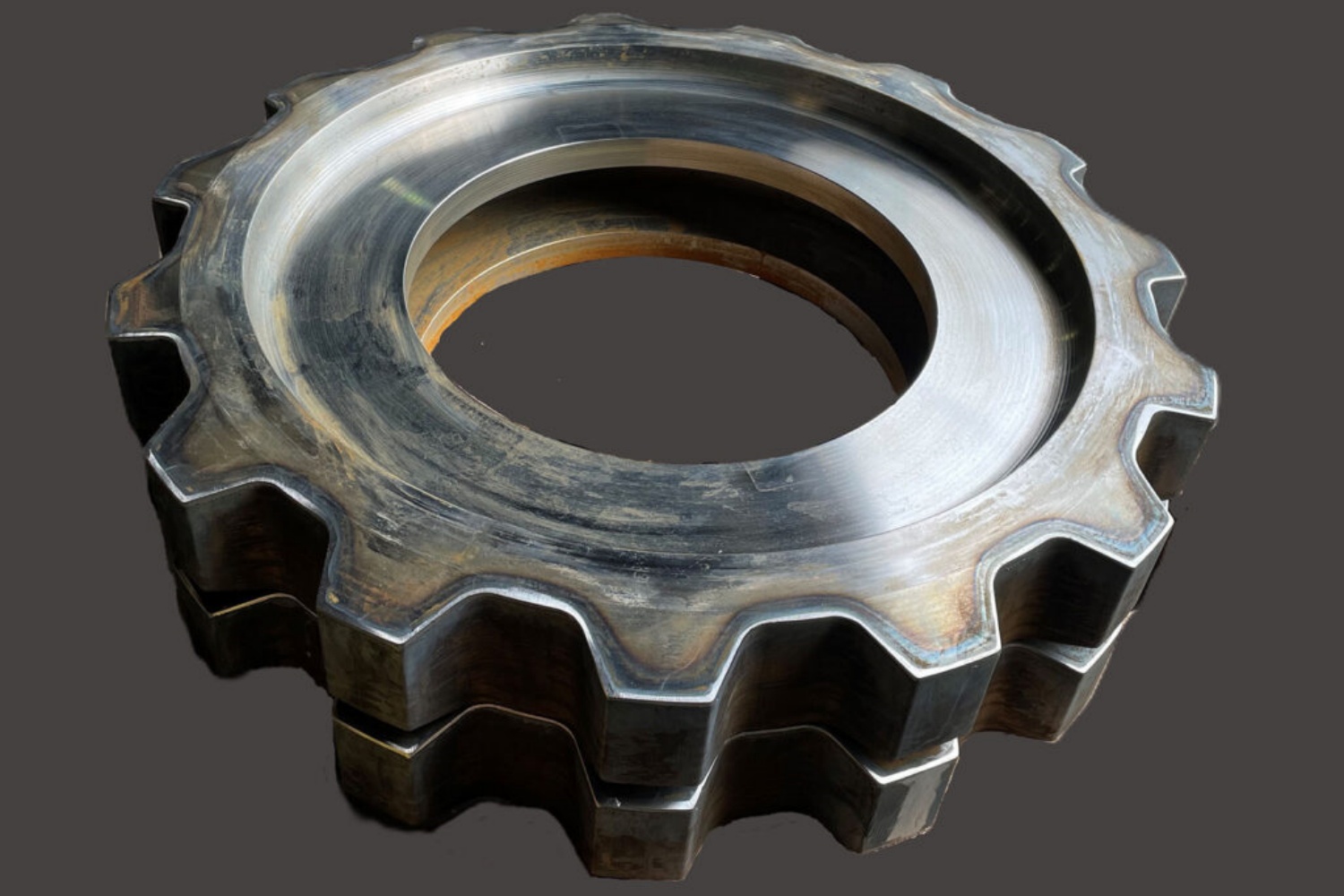

Although as an ‘inconspicuous’ gadget, mechanical gear will affect the operation of the entire machine if it could not function well. Therefore, it can be known that the maintenance of mechanical gears is very important, so how shall the maintenance of mechanical gears be done? Let’s check the following points together.

- Mechanical gears need to be regularly lubricated

The easiest way is to use lubricating oil. The frictional resistance generated during operation is reduced when the friction between the gears is decreased with the use of lubricating oil, which plays an important role in reducing the wear of the gears, so that the service life of the mechanical gears can be prolonged.

- External care of mechanical gears

Please pay attention to whether there is box to protect the mechanical gears during working. If there is no box protection, the gears should be equipped with a corresponding safety cover in time, which can prevent other objects from falling on the them, thereby avoiding the immediate damage of the mechanical gears.

- Precautions when assembling mechanical gears

To make the mechanical gears run better, when assembling them, it is necessary to ensure that the centerline of the moving shaft and the mechanical gear coincide, and the reference plane of the mechanical gear should be perpendicular to the centerline of the moving shaft, so that the mechanical gear will be running smoother.

The above are the maintenance methods of mechanical gears in daily life. If these points are noted, then the gears inside the machine can be used for a longer time, and there is no need to worry about the accident that the machine will stop running due to the failure of the mechanical gear.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]