Industrial gears are a crucial component in various machines and industrial processes. They are used for transmitting power and motion between different components. While industrial gears share many similarities, there are several differences that set them apart.

Design Differences

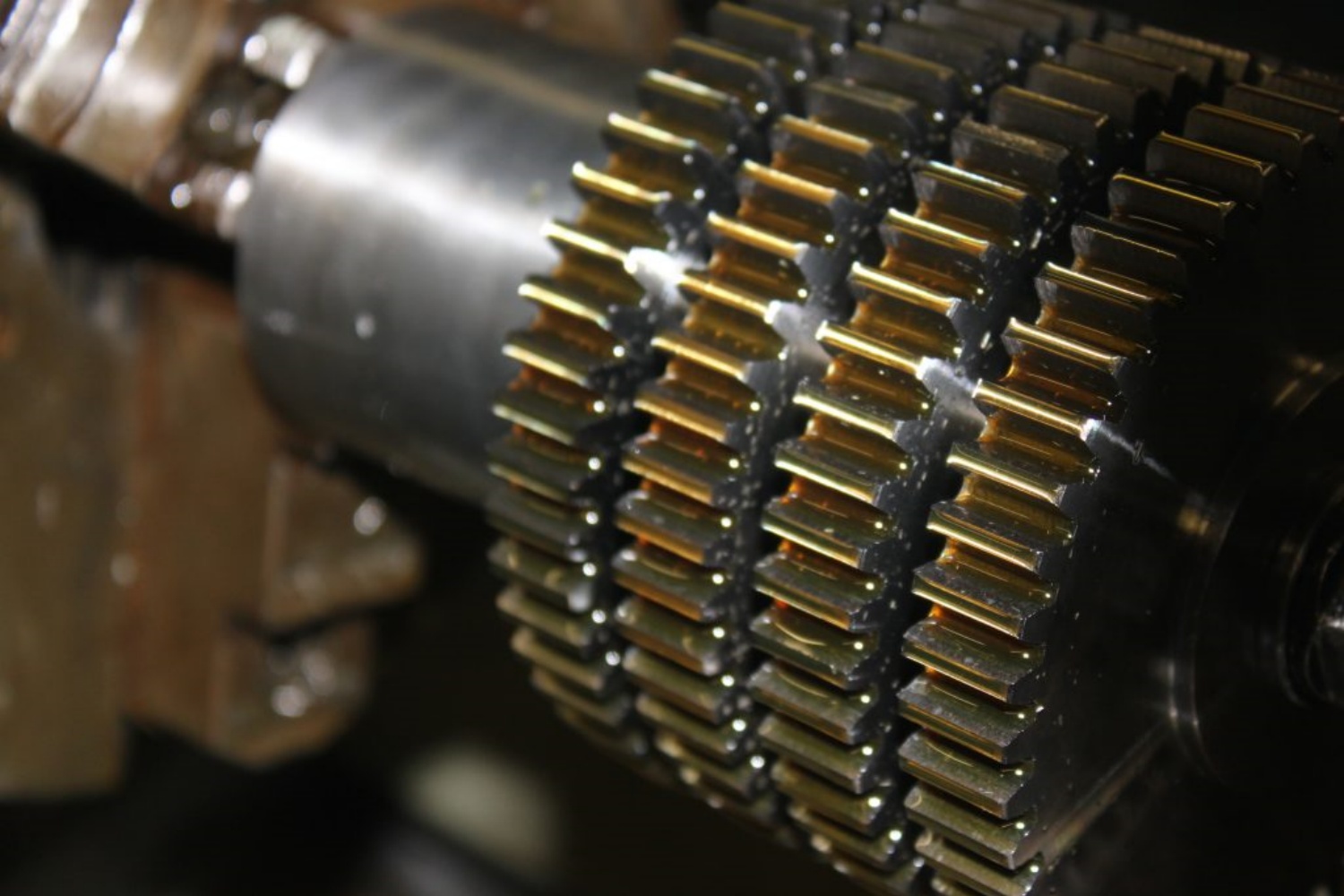

Industrial gears can be classified into two main categories: spur gears and helical gears. Spur gears have straight tooth profiles that mesh together in a way that allows for efficient power transmission. They are commonly used in applications where high loads and accurate alignments are required. Helical gears, on the other hand, have teeth that are slanted at an angle, allowing them to transmit power more smoothly. They are typically employed in applications where noise and vibration are critical factors.

Material Difference

Industrial gears are often made from high-quality materials to ensure durability and performance. The most common materials for industrial gears include carbon steel, alloy steel, and stainless steel. Carbon steel is often used for gears with high strength requirements, while alloy steel is preferred for high-speed and high-load applications. Stainless steel is commonly used in corrosive environments to prevent premature failure.

Application Difference

Industrial gears are used in a wide range of applications, including but not limited to:

Machinery: industrial gears are essential components in various machines, such as conveyor systems, cranes, and presses. They transmit power and motion between different components of these machines.

Energy: industrial gears are used in wind turbines, solar panels, and other renewable energy systems to convert rotational motion into useful energy.

Transportation: gears in automobiles and trains help transmit power from the engine to the wheels or tracks, enabling efficient propulsion.

Manufacturing: industrial gears are employed in factories and manufacturing plants to move products, operate machinery, and control processes.

Mining and Construction: large industrial gears are used in mining equipment and construction machinery to handle heavy loads and perform precision operations.

Difference in Operation

Industrial gears operate under a wide range of conditions, including high loads, high speeds, and varying environments. To ensure smooth operation, industrial gears must be lubricated properly. The type of lubricant used depends on the application and operating conditions. For example, grease is commonly used for lubricating low-speed, low-load gears, while oil is preferred for high-speed and high-load applications. Proper lubrication extends the lifespan of industrial gears and improves their overall performance.

Difference in Maintenance

Maintenance requirements for industrial gears vary based on application type and operating conditions. Generally speaking, industrial gears require periodic inspection to ensure proper alignment, tooth condition and lubrication levels. In some cases, maintenance intervals may need to be shortened due to heavy loads or high speed operation. Regular inspections can catch potential problems before they cause equipment failure or performance issues.

Industrial gears play a crucial role in various industrial applications. While they share many similarities, there are several differences that set them apart based on their design, material, application, operation, and maintenance requirements. Understanding these differences is essential for selecting the appropriate industrial gear for a specific application while ensuring optimal performance and durability.

More:Custom Gears: Where Precision Meets the Unique Demands of Your Industry

CONTINUE READING

Related Posts

V-pulleys are a crucial component in industrial applications, particularly in belt drive systems. They are responsible for transferring power from […]

The agricultural machinery sprocket is a crucial component in various farming practices, playing a significant role in the efficiency and […]

The spur gear, a fundamental component in numerous mechanical systems, has witnessed numerous iterations and enhancements over the years. Its […]