In the world of agriculture, the efficiency and reliability of machinery play a pivotal role in ensuring high productivity and minimal downtime. Among the various components that make up farming equipment, sprockets stand out as critical elements that drive the functionality of machinery. High-quality sprockets can significantly enhance the reliability and efficiency of farming equipment, leading to improved performance and reduced maintenance costs.

The Importance of Sprockets in Agricultural Machinery

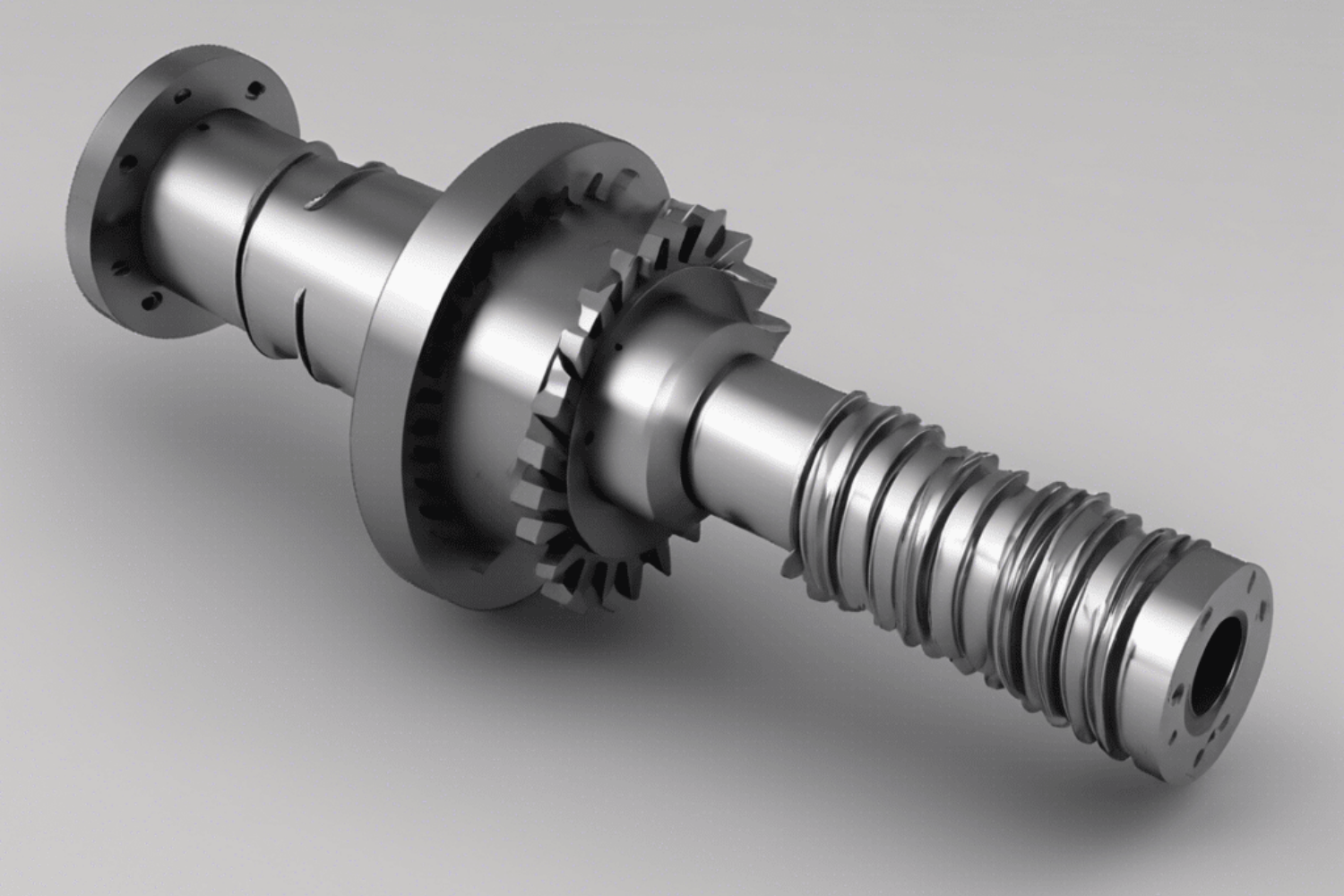

Sprockets are toothed wheels that interact with chains or belts to transmit rotational motion in machinery. In agricultural equipment, sprockets are utilized in various applications, including tractors, harvesters, and conveyor systems. They are responsible for the smooth operation of machinery, ensuring that power is efficiently transferred from the engine to the working parts of the equipment.

The Impact of High-Quality Sprockets

Using high-quality sprockets in farming equipment offers several benefits. Firstly, they provide superior strength and durability, which is crucial in handling the heavy loads and harsh conditions often encountered in agricultural settings. High-quality sprockets are typically made from robust materials such as hardened steel or cast iron, ensuring they can withstand wear and tear over time.

Furthermore, precision-engineered sprockets ensure a perfect fit with chains or belts, reducing the risk of slippage and misalignment. This precision not only improves the efficiency of power transmission but also minimizes the risk of unexpected breakdowns, which can be costly in terms of both time and money.

Design Considerations for Agricultural Sprockets

When designing sprockets for agricultural machinery, several factors need to be considered. The number of teeth, pitch diameter, and the profile of the teeth are crucial in determining the performance and compatibility of the sprocket with the rest of the machinery. The material choice is also vital, as it needs to be tough enough to withstand the rigors of farming operations while being resistant to corrosion and wear.

Advancements in Sprocket Technology

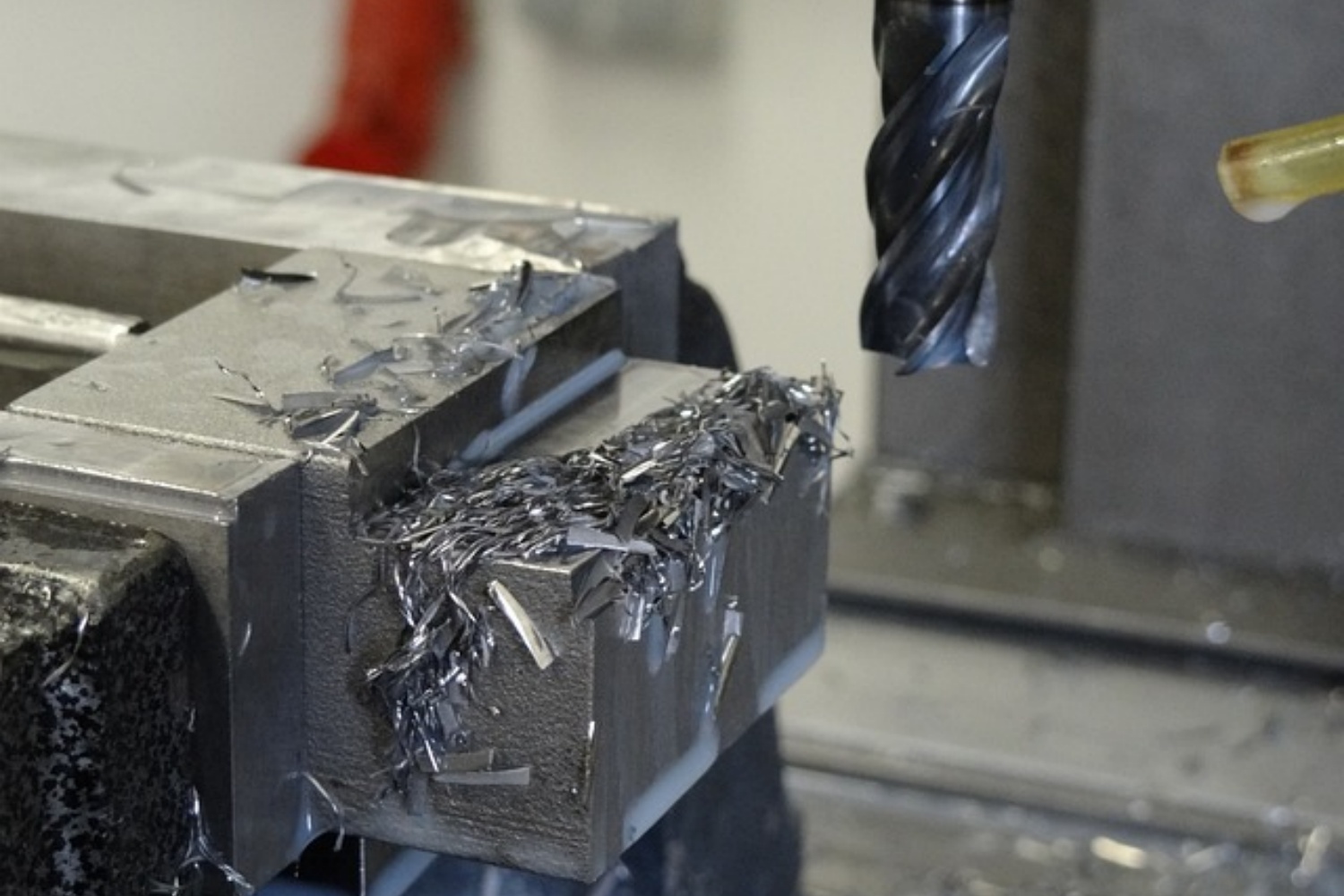

The agricultural industry has seen significant advancements in sprocket technology in recent years. Innovations such as surface hardening techniques and the use of high-grade alloys have led to the development of sprockets that are more durable and efficient. Additionally, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) has enabled the production of sprockets with higher precision and better performance characteristics.

Maintenance and Care of Sprockets

Proper maintenance and care are essential to extend the lifespan of sprockets and ensure the continuous reliability of farming equipment. Regular inspections should be conducted to check for signs of wear, such as tooth wear or damage, and misalignment. Lubrication of the sprockets and chains is also important to reduce friction and prevent premature wear. When replacing sprockets, it is crucial to select ones that match the specifications of the original equipment to maintain optimal performance.

High-quality sprockets are indispensable components in the realm of agricultural machinery. Their role in enhancing the reliability and efficiency of farming equipment cannot be overstated. By investing in well-designed, durable sprockets and adhering to proper maintenance practices, farmers and agricultural businesses can ensure the longevity and optimal performance of their machinery, ultimately leading to increased productivity and reduced operational costs.

CONTINUE READING

Related Posts

Machining plays a pivotal role in modern manufacturing, transforming raw materials into precise components essential for various industries. The process […]

Splined shafts are essential components in various mechanical systems, designed to transmit torque and rotational motion efficiently. Their unique design […]

In the realm of mechanical design and engineering, the choice between custom and standard gear sets is pivotal. This decision […]