In the world of machinery, understanding each component’s function is crucial for anyone involved in the field, whether professionally or as an enthusiast. Among these components, sprockets play a pivotal role in ensuring smooth and efficient operation. Despite their small size, sprockets are essential to the performance of various machines, and their significance necessitates a deeper understanding of their mechanisms and applications.

What are Sprockets?

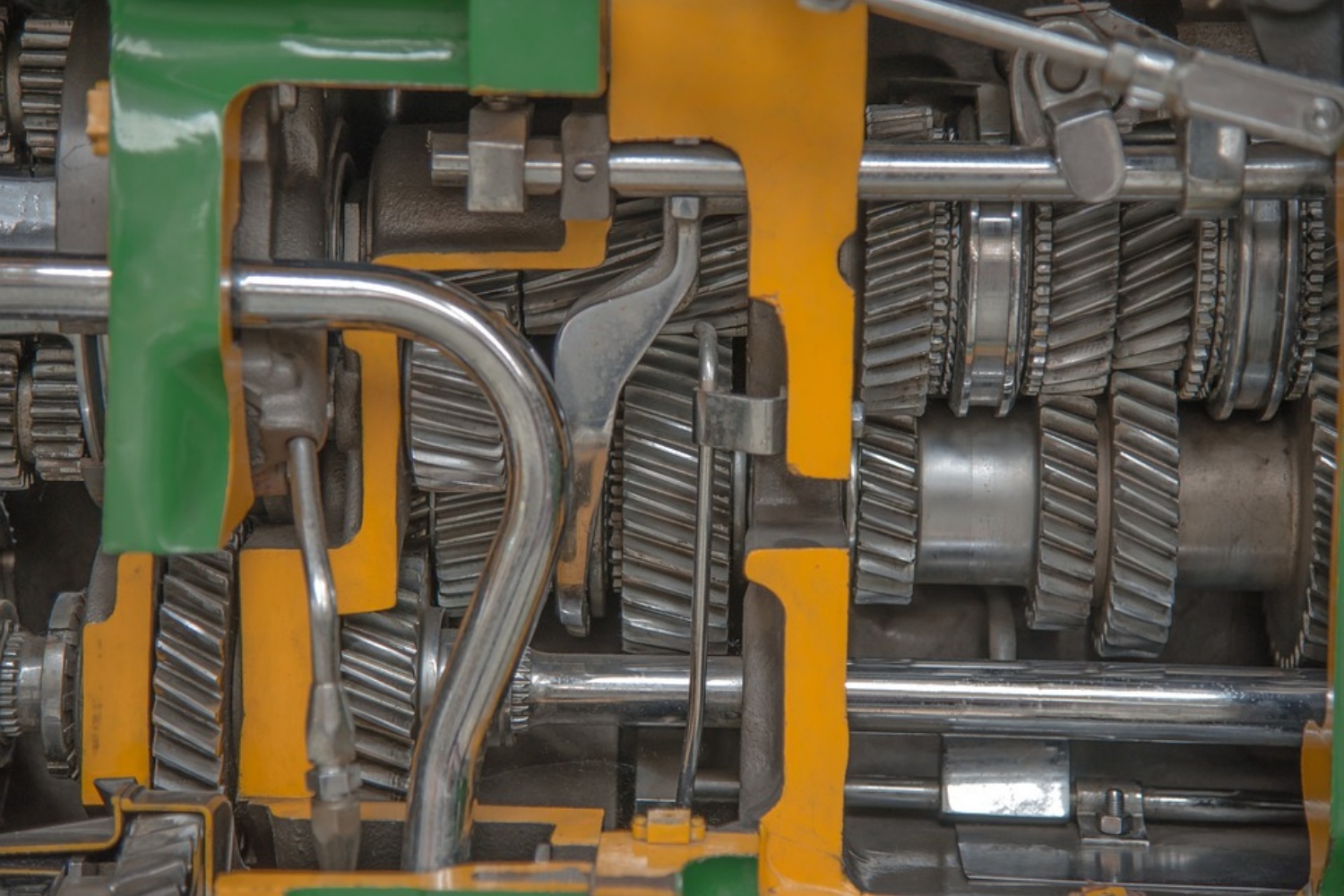

Sprockets are mechanical wheels with teeth or spikes designed to engage with a chain or belt, facilitating the rotation and movement of the wheel. This engagement ensures synchronized movement, allowing the sprocket and belt to operate efficiently together. It is crucial for the sprocket and the belt to share the same thickness to ensure optimal performance. Sprockets are universally similar in design and are extensively used in various industries, including automotive, cycling, and machinery, to mechanize multiple functions and applications.

Different Types of Sprockets

Sprockets come in various shapes, sizes, and tooth configurations, each tailored to specific applications. Here are the primary types of sprockets:

- Double Duty Sprockets: Featuring two teeth on every single pitch, these sprockets are designed for applications requiring higher durability and efficiency.

- Multiple Strand Sprockets: Used in situations where additional power and torque are necessary, these sprockets can accommodate multiple chains, providing enhanced strength and performance.

- Idler Sprockets: These sprockets are used with long chains to eliminate uneven load distribution, ensuring smoother operation and reducing wear and tear.

- Hunting Tooth Sprockets: With an uneven number of teeth, these sprockets are designed to last longer than other types, as the wear is distributed more evenly across the teeth.

Working Mechanism of Sprockets

The working mechanism of sprockets is relatively straightforward. Typically, a pair of sprockets is involved, with one acting as the “driver” and the other as the “driven.” These sprockets are connected by a chain or belt, and when force or motion is applied to the driver sprocket, it transfers power to the driven sprocket. This transfer of power can alter the torque or speed of a mechanical system, depending on the sprockets’ configuration.

Sprockets with more teeth can handle larger loads but also generate more friction, which can slow down movement. Over time, the notches in the sprockets wear down due to the chain passing over them. If the teeth become sharpened or caught, it indicates that the sprockets need replacement to maintain efficient operation.

Common Uses of Sprockets

Sprockets are employed in a wide range of applications, demonstrating their versatility and importance in various industries:

- Bicycles: One of the most common uses of sprockets is in bicycles, where they are used to pull a connected chain, translating the rider’s foot motion into the rotation of the wheels. This mechanism is fundamental to the functioning of a bicycle, allowing it to move forward.

- Tracked Vehicles: Sprockets are also crucial in tracked vehicles like tanks and agricultural machinery. They align with the links in the tracks and pull them, enabling the vehicle to move. This design allows tracked vehicles to traverse uneven terrain more effectively, as the vehicle’s weight is evenly distributed along the track.

- Film Cameras and Projectors: In the realm of film, sprockets are used to hold the film in place and move it during the process of taking pictures or projecting images. They ensure the film advances correctly, maintaining the proper sequence of frames in cameras and projectors.

Materials and Durability

Sprockets are typically made from durable materials such as steel, stainless steel, or aluminum. The choice of material depends on the specific application and the required durability. For high-stress environments, steel sprockets are often preferred due to their strength and resistance to wear. Aluminum sprockets, while lighter, are used in applications where weight reduction is essential without compromising performance.

Maintenance and Replacement

Proper maintenance of sprockets is essential to ensure their longevity and optimal performance. Regular inspection for signs of wear, such as sharp or worn-down teeth, is necessary. Lubrication of the chain or belt can also reduce friction and wear, prolonging the sprocket’s lifespan. When sprockets do show significant wear, timely replacement is crucial to prevent damage to other components and maintain the efficiency of the system.

Sprockets may seem like a small part of a machine, but their role is undeniably significant. From bicycles and tracked vehicles to film projectors, sprockets ensure the smooth and efficient operation of various systems. Understanding the different types of sprockets, their working mechanisms, and their applications provides valuable insight into the intricate world of machinery. By appreciating the importance of sprockets, professionals and enthusiasts alike can ensure their machines run smoothly and efficiently, ultimately enhancing performance and longevity.

CONTINUE READING

Related Posts

In industrial machinery, V-groove pulleys are a critical component, transferring power efficiently and ensuring the smooth operation of various mechanical […]

Spur gears are among the simplest and most widely used gears in mechanical engineering and industrial applications. Their straightforward design […]

Taper lock bushes are essential components used to securely attach pulleys, gears, and other mechanical elements to shafts. Their design […]