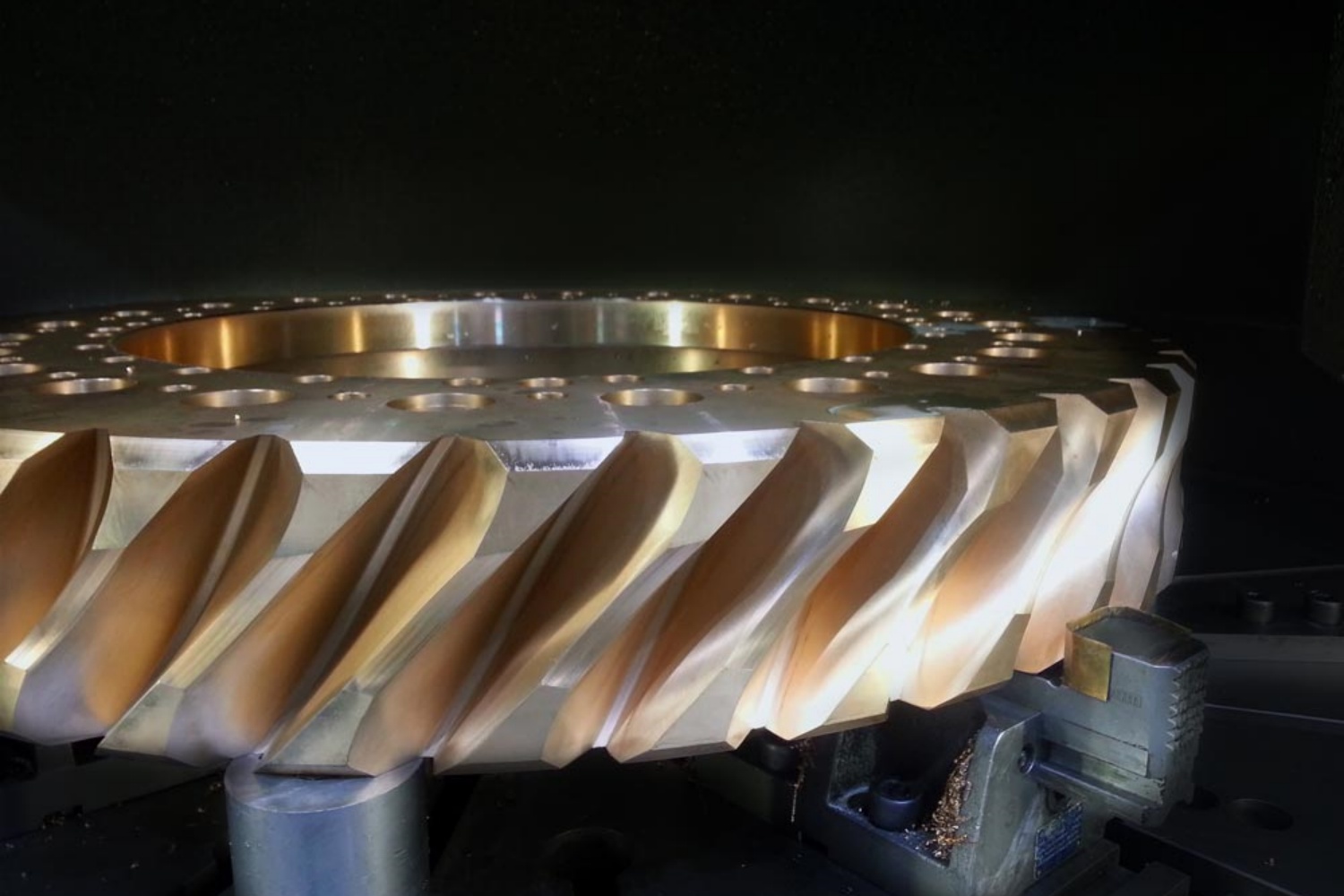

Copper alloys, particularly bronze, boast unique characteristics crucial for minimizing wear in gear applications, especially when paired with steel components. Within gear reducers and similar mechanisms, bronze gears frequently engage with steel worm gears or steel spur gears, leveraging the disparity in hardness between the materials. This deliberate combination reflects a principle akin to that governing bronze sleeve bearings and harder steel shafts, ensuring sacrificial wear of the bronze while preserving the integrity of the steel.

The choice of bronze to steel pairing offers several advantages:

- Sacrificial Wear: Bronze-to-steel interaction results in the erosion of the bronze surface while maintaining the steel’s integrity.

- Reduced Friction: Friction forces are significantly lower compared to steel-to-steel interactions.

- Wear Mechanism: At lower speeds, the surface roughness of mating parts leads to contact between asperities, causing wear. In bronze-to-steel pairs, the stronger steel asperities shear off the weaker bronze asperities, mitigating wear.

Engineering the Perfect Gear Bronze Alloy: Balancing Strength, Friction, and Wear Characteristics

To optimize these benefits, metallurgical and mechanical engineers have developed specific bronze alloys tailored to minimize wear while retaining essential properties. The ideal bronze alloy for gear applications should exhibit:

- Sufficient strength to withstand operational loads.

- A low coefficient of friction when paired with steel.

- Minimal wear under operating conditions.

While many bearing bronzes incorporate lead to reduce friction coefficients, excessive lead content can weaken the material. Therefore, for gear bronze applications, lead content must be carefully regulated. Some gear bronzes incorporate trace amounts of lead to enhance machinability while maintaining adequate strength.

Optimal Wear Properties in Copper Alloys for Gears: Exploring Aluminum, Manganese, and Tin Bronzes

The most favorable wear properties are observed in two primary groups of copper alloys:

- Aluminum and Manganese Bronzes: These alloys, characterized by a strong matrix embedded with hard phases, wear sacrificially against steel mating parts. However, their asperities may develop abrasive oxides over time, diminishing their long-term effectiveness.

- Tin Bronzes: Tin content up to approximately 10% enhances the strength and hardness of these alloys, inhibiting slip between crystal layers. Tin bronzes form a low-friction layer on mating steel parts, making them the preferred choice for nonferrous gears due to their superior wear characteristics.

Tin bronze’s effectiveness lies in the gradual deposition of bronze asperities onto steel surfaces during the “wearing-in” process, leading to decreased wear and friction forces over time.

Advancements in Gear Bronze Manufacturing: Innovations in Alloy Composition and Casting Techniques

The development of gear bronzes has resulted in a series of alloys specified under ASTM B 427-93A, each tailored to specific applications. Notably, Copper Alloy C92900 stands out for its diverse composition, including 2.5% lead content for machinability and 3.5% nickel content for enhanced corrosion resistance and improved casting properties.

However, producing gear bronzes through wrought processing methods such as extrusion or forging is impractical due to the high tin content, which causes billets to fracture. Instead, gear bronzes must be cast using specialized methods such as sand casting, chill casting, or continuous casting.

Continuous casting, in particular, has revolutionized gear bronze production since its inception in the 1950s. This method yields bar and tube products with small, uniform crystal sizes, resulting in superior mechanical properties and wear resistance compared to other casting methods.

The selection and development of gear bronze alloys, especially those with optimized tin content, play a crucial role in ensuring efficient and reliable gear operation across various industrial applications. Continuous advancements in casting technology continue to elevate the performance and durability of gear bronzes, reinforcing their status as indispensable components in the realm of mechanical engineering.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]