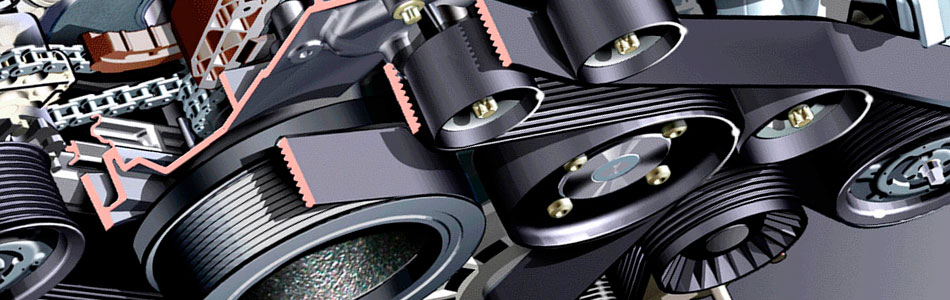

Pulleys are an essential component in mechanical power transmission systems, used to transfer power from one rotating shaft to another. Pulleys come in a variety of sizes, shapes, and designs, and each has its unique features and advantages. One type of pulley that is widely used in many industries is the three-groove pulley. In this article, we will explore the benefits and uses of three-groove pulleys.

What is a Three-Groove Pulley?

A three-groove pulley is a type of V-belt pulley that has three grooves on its circumference. The grooves are designed to accommodate multiple belts, providing a higher power transmission capability. The pulley’s design helps to distribute the load across multiple belts, increasing their efficiency and durability. Three-groove pulleys are available in different diameters, widths, and bore sizes, making them suitable for various applications.

Benefits of Three-Groove Pulleys

Increased Power Transmission Capacity: Three-groove pulleys are designed to transmit more power than single-groove pulleys. The multiple grooves provide more surface area for the belts to grip, resulting in a higher power transmission capability. This makes three-groove pulleys ideal for high-power applications.

Enhanced Belt Life: Three-groove pulleys distribute the load evenly across multiple belts, reducing the stress on individual belts. This results in a longer belt life and reduced maintenance costs. The multiple grooves also provide more contact area between the belts and the pulley, which reduces slip and wear.

Improved Efficiency: The design of three-groove pulleys allows for better belt tension, resulting in improved efficiency. The even distribution of the load across multiple belts reduces belt slip, which results in higher efficiency and less power loss.

Cost-Effective: Three-groove pulleys are cost-effective and offer good value for money. The increased power transmission capacity and longer belt life result in reduced downtime and maintenance costs.

Applications of Three-Groove Pulleys

Three-groove pulleys are used in a variety of industries and applications, including:

- Industrial Machinery: Three-groove pulleys are used in many industrial applications, including conveyor systems, compressors, and pumps. Their ability to handle high loads and transmit more power makes them ideal for heavy-duty applications.

- Automotive Industry: Three-groove pulleys are used in the automotive industry for various applications, including power steering systems and air conditioning compressors.

- Agricultural Machinery: Three-groove pulleys are also used in agricultural machinery, including tractors and combines. They are used to transfer power from the engine to various components, such as the fan, water pump, and alternator.

- HVAC Systems: Three-groove pulleys are used in HVAC systems, including air handling units and fan systems. They are used to transfer power from the motor to the fan, reducing the load on the motor and increasing efficiency.

Conclusion

Three-groove pulleys are an essential component in many mechanical power transmission systems. Their design provides increased power transmission capacity, improved efficiency, and longer belt life. They are used in a variety of applications, including industrial machinery, automotive, agricultural machinery, and HVAC systems. When selecting a three-groove pulley, it is important to consider the application’s requirements, including power transmission capacity, speed, and load. With proper selection and maintenance, three-groove pulleys can provide reliable and efficient power transmission for many years.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]