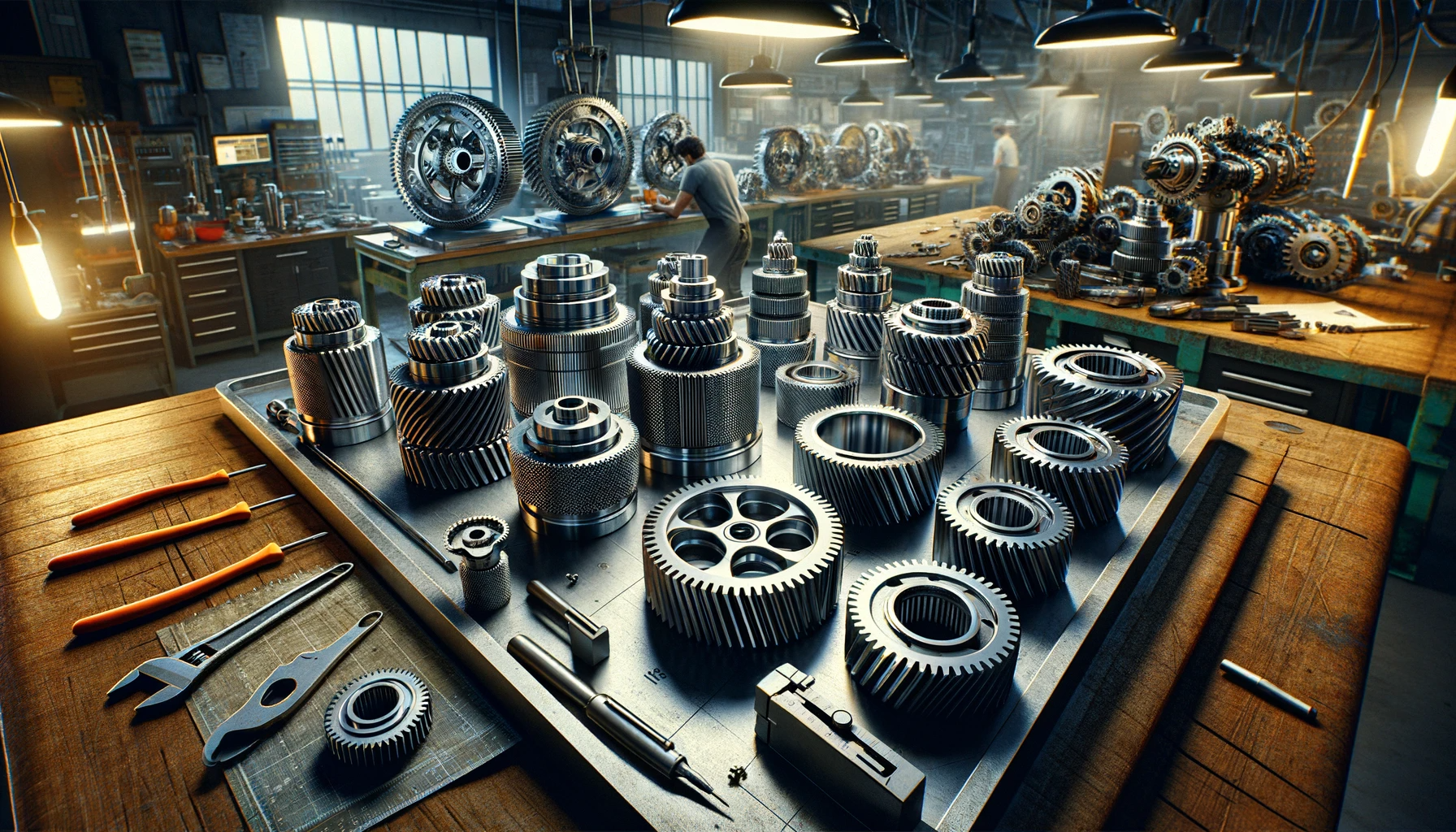

In the realm of machinery and industrial applications, achieving optimal performance often hinges on the precision and reliability of gears. As industries evolve and demand specialized solutions, the spotlight turns to the art of gear customization—a process that intricately navigates the complexities of tailored manufacturing.

In the ever-evolving landscape of industrial machinery, off-the-shelf solutions may fall short of meeting the unique demands of certain applications. This is where the significance of gear customization comes to the forefront.

Understanding Custom Gear Manufacturing:

Custom gear manufacturing is a multifaceted process that begins with a meticulous understanding of the application’s requirements. Whether it’s gearing for automotive systems, aerospace applications, or specialized machinery, the customization process commences with a detailed analysis of factors such as torque, speed, load distribution, and environmental conditions.

Material Selection:

One of the pivotal decisions in gear customization is the selection of materials. Different applications demand different material properties. From traditional steel alloys to advanced composite materials, manufacturers must weigh factors like durability, weight, and cost-effectiveness to arrive at the optimal material for the custom gears.

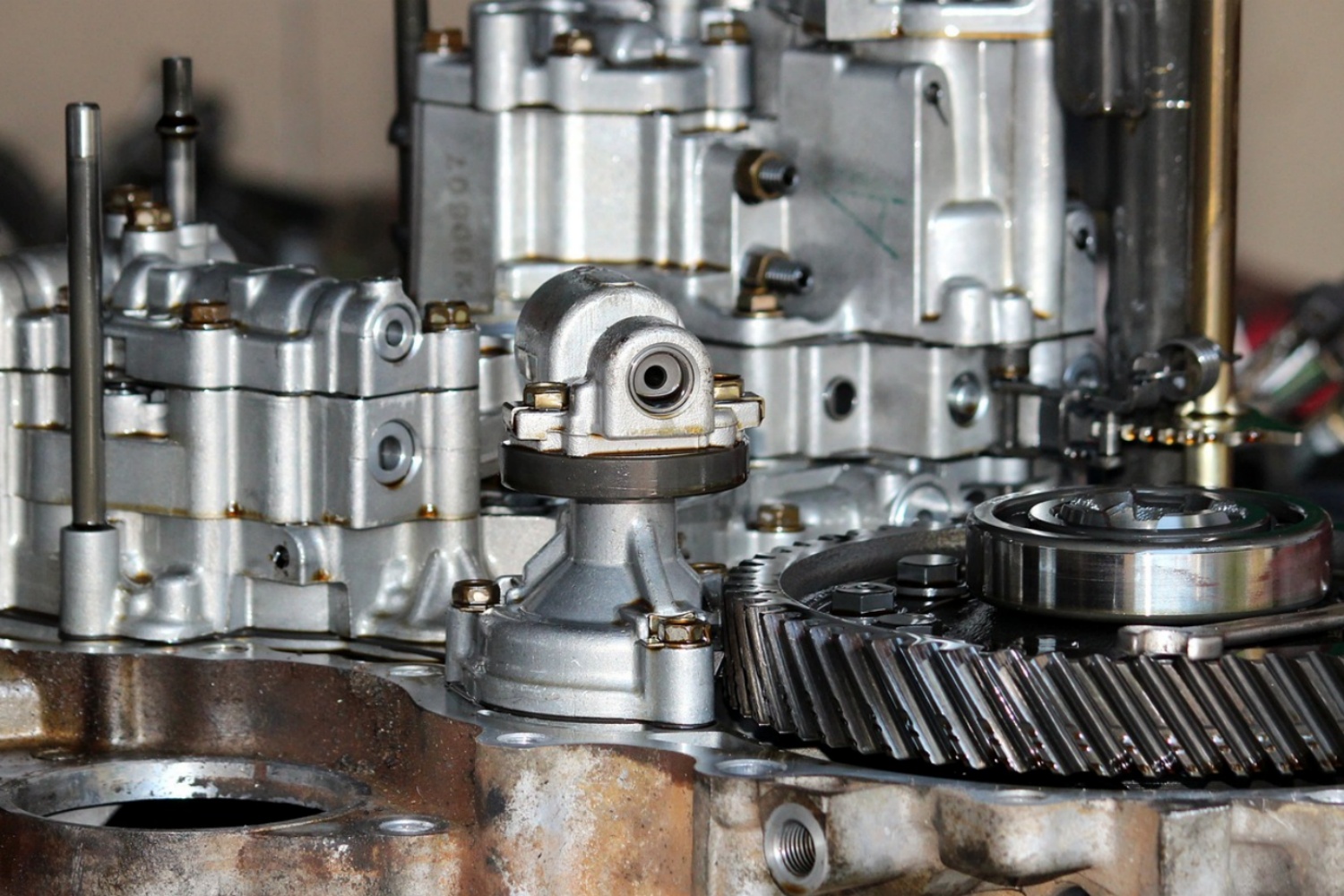

Precision Engineering:

The heart of gear customization lies in precision engineering. Unlike mass-produced gears, custom gears require a level of precision that often involves advanced machining processes. Computer Numerical Control (CNC) machining, gear hobbing, and grinding are some of the techniques employed to ensure each tooth is perfectly formed, contributing to smooth operation and longevity.

Gear Tooth Profile Design:

Custom gears often necessitate a specific tooth profile to accommodate the unique load distribution in a given application. The design process involves a careful balance between tooth strength, engagement characteristics, and minimizing noise and vibration. Advanced software and simulations play a crucial role in optimizing these profiles.

Heat Treatment and Finishing:

The customization journey extends to heat treatment processes tailored to the chosen material. Heat treatment not only enhances the hardness and strength of gears but also influences their wear resistance. Furthermore, finishing processes, such as precision grinding and coating applications, contribute to the final product’s longevity and performance.

Quality Assurance:

Ensuring the reliability of custom gears involves rigorous quality assurance measures. Precision inspections, including dimensional checks, material analysis, and performance testing, are integral steps to guarantee that each customized gear meets or exceeds the specified standards.

Case Studies:

Illustrating the article with real-world case studies provides tangible examples of successful gear customization. These could include instances where tailored gears have significantly improved efficiency, reduced maintenance costs, or enabled the machinery to operate in challenging environments.

As industries continue to push the boundaries of innovation, the role of customized gears becomes increasingly pivotal. Navigating the complexities of tailored manufacturing requires a harmonious blend of engineering expertise, cutting-edge technology, and a profound understanding of application-specific requirements. In this pursuit of perfection, gear customization emerges as a beacon, guiding industries towards unparalleled precision and performance.

CONTINUE READING

Related Posts

In the world of mechanical engineering, the importance of power transmission components cannot be overstated. Among these, V-pulleys play a […]

In the world of machinery, understanding each component’s function is crucial for anyone involved in the field, whether professionally or […]

Custom sprockets stand as testament to the precision and innovation inherent in modern engineering. Each custom sprocket begins its journey […]