In the world of machinery, gears and sprockets are essential components that allow for efficient transmission of power. While they may seem similar at first glance, there are distinct differences between a gear and a sprocket.

Definition and Function

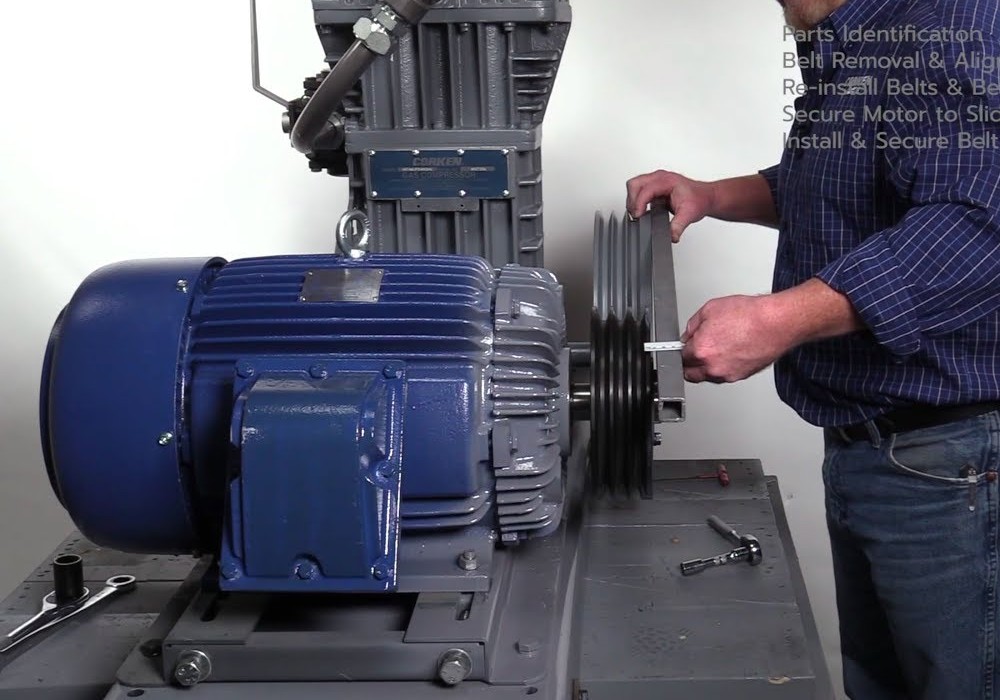

A gear is a toothed wheel designed to transmit torque and rotate at a specific speed. It is used to convert a high-speed input into a slower, but higher-torque output. Gears are typically found in machinery such as automobile engines, transmissions, and industrial equipment.

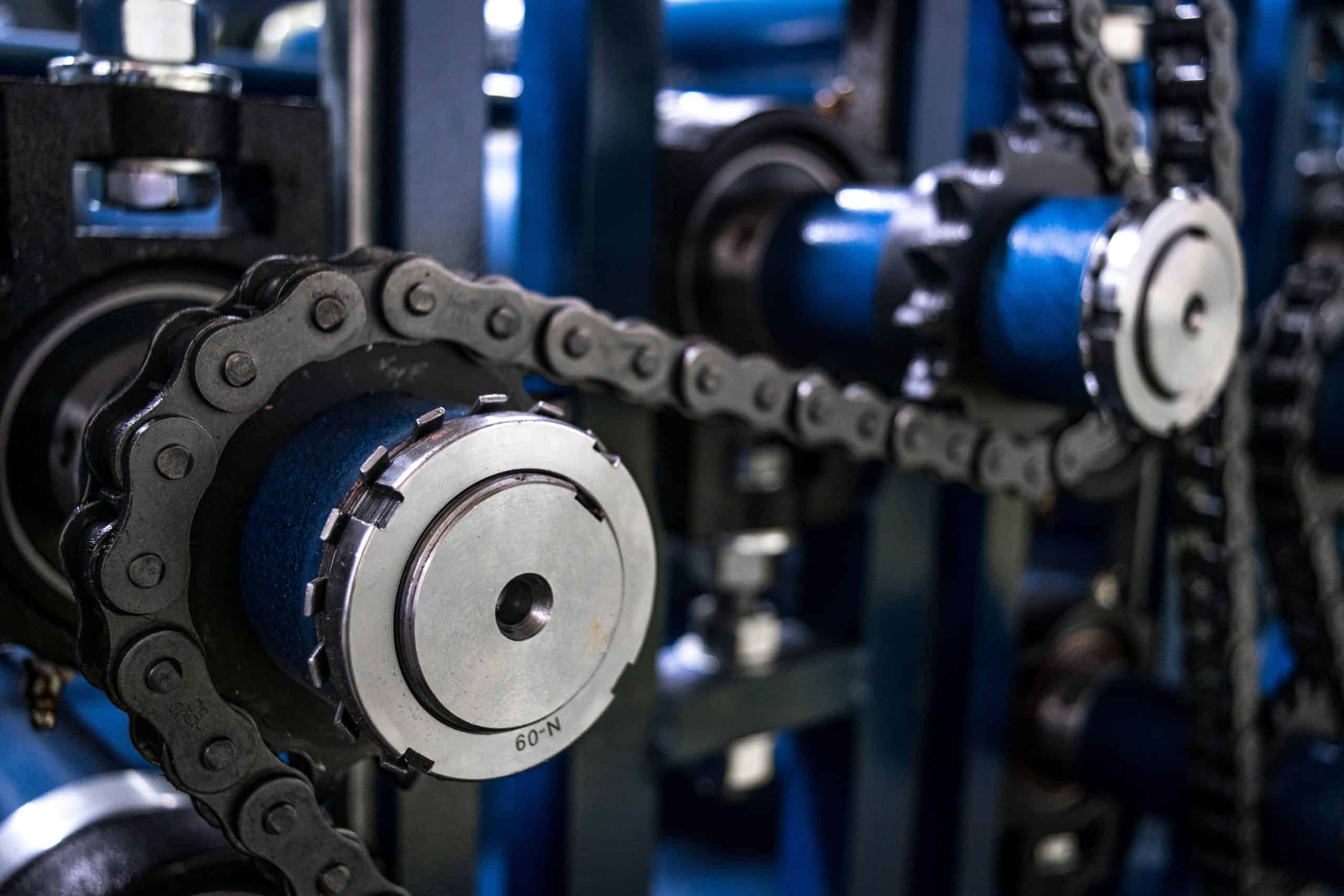

On the other hand, a sprocket is a toothed wheel with a specific number of teeth that meshes with a chain or belt to transmit power. It is used to convert linear motion into rotational motion or vice versa. Sprockets are commonly found on bicycles, industrial conveyor belts, and agricultural machinery.

Design and Structure

Gears are designed with different tooth profiles, such as spur, helical, or bevel, depending on the specific application requirements. They have a solid structure with teeth that are evenly spaced around the circumference. Gears can be made from a variety of materials such as steel, bronze, or plastic.

Sprockets, on the other hand, have a simpler design with fewer teeth and a smaller diameter than gears. They are typically made from steel or plastic and have a thin cross-section. Sprockets are specifically designed to mesh with chains or belts and provide a flexible means of power transmission.

Power Transmission Efficiency

Gears are generally more efficient in power transmission compared to sprockets. The engagement of gear teeth with each other provides a more secure coupling and reduces slippage. This results in more torque being transmitted through the gear system.

Sprockets, on the other hand, may experience some degree of slippage when meshing with chains or belts. This can result in power loss and reduced efficiency. However, sprockets are often used in situations where flexibility and space constraints are important considerations.

Application Suitability

Gears are commonly used in applications where high torque transmission and accurate speed control are essential. They are found in automobile engines, industrial machinery, and precision instruments requiring precise motion control. Gears provide a robust and reliable means of power transmission in these settings.

Sprockets are more suitable for applications where linear-to-rotary conversion is required or where space constraints limit the use of larger gears. They are commonly used on bicycles, industrial conveyor belts, agricultural machinery, and other situations where flexibility in power transmission is essential.

Maintenance and Repair

Gears require regular maintenance and lubrication to ensure smooth operation and extend their service life. Cleaning and inspection of the gear system should be done on a regular basis to detect any damage or wear that may require repair or replacement.

Sprockets also require regular inspection for wear or damage but are generally simpler to maintain compared to gears. Since sprockets are typically smaller and have a simpler design, they can be more easily replaced if damaged.

Gear vs. Sprocket

There are distinct differences between a gear and a sprocket. Gears are larger, more complex components designed for efficient power transmission in applications requiring high torque and accurate speed control. On the other hand, sprockets are smaller, simpler components used for linear-to-rotary conversion or in situations where space constraints limit the use of larger gears. Understanding the unique characteristics and suitability of each component is essential when selecting the appropriate component for your specific application requirements.

More: Embrace Quality and Precision: Choose Shanghai Oris for Your Industrial Sprockets Needs in the UK

CONTINUE READING

Related Posts

A V belt adjustable pulley is a type of pulley that can adjust the center distance between two pulleys by […]

A pulley is a vital component of power transmission systems that are used in various industrial applications. It is responsible […]

V-belt pulleys are an essential component of any machinery or equipment that requires power transmission. They are responsible for transmitting […]