In the realm of industrial automation, the significance of gears and pulleys within the machinery cannot be overstated. These components are pivotal in enhancing the efficiency, safety, and reliability of industrial robots, which are increasingly becoming integral to manufacturing processes worldwide. I will teach you about the critical role of pulleys and gears in industrial machines, emphasizing their meaning, the importance of maintenance, and guidelines for safe use.

The Essence of Gears and Pulleys in Industrial Machines

Gears and pulleys are fundamental in transmitting power and motion within industrial robots and machines. They enable these machines to perform a wide range of tasks with precision and efficiency. By converting rotational motion into linear motion, or vice versa, and by altering the speed and torque of the machine operation, gears and pulleys facilitate the execution of complex tasks that would be challenging, if not impossible, for human workers. This capability not only boosts productivity but also enhances the safety of the workplace by taking over tasks that are hazardous for humans.

Care and Maintenance: Ensuring Longevity and Performance

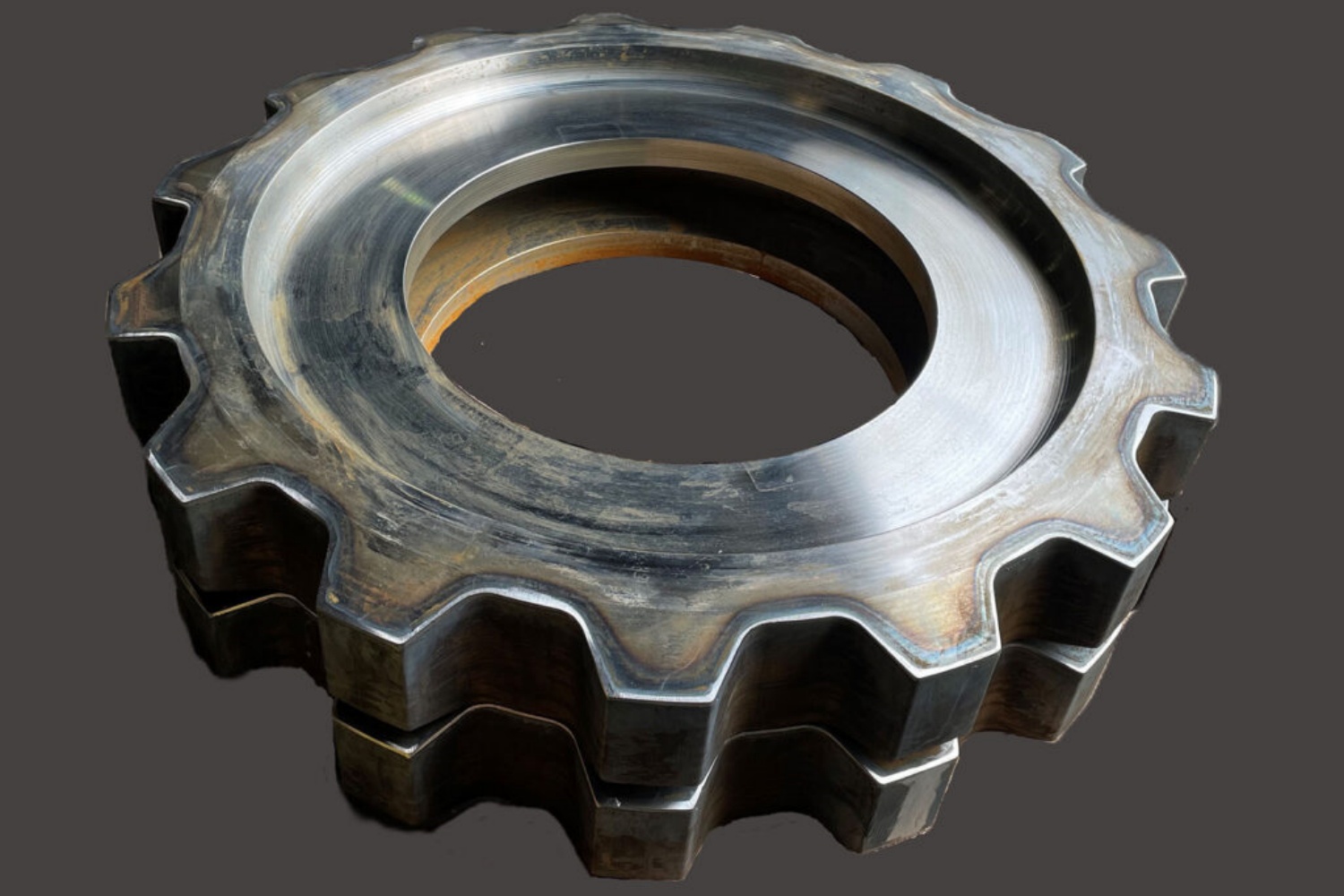

The longevity and optimal performance of industrial robots heavily depend on the regular maintenance of their gears and pulleys. Signs of wear and tear, such as poor belt tension, misalignment, and contamination, can significantly impair their functionality. Regular visual inspections are crucial, especially after periods of heavy use, to identify any potential issues early on. Daily checks for damage, wear, and the presence of dust, dirt, or debris are essential preventive measures. Additionally, monthly cleaning and ventilation of the robot’s controller, along with a thorough inspection while the robot is in motion, can preempt many operational problems.

Proper maintenance also involves addressing grease or oil leaks promptly, ensuring that all mechanical components are adequately lubricated. This not only prevents premature wear but also maintains the efficiency and reliability of the machine. By adhering to a rigorous maintenance schedule, industrial robots can continue to operate at peak efficiency, thereby minimizing downtime and maximizing productivity.

Safe Use: Guidelines and Best Practices

The safe use of gears and pulleys in industrial robots is paramount to prevent accidents and ensure the well-being of the workforce. This begins with the correct installation of new gears and pulleys, following the original equipment manufacturer’s (OEM) recommendations and tolerance specifications. Ensuring proper alignment, checking for radial and shaft run-out, and addressing any issues with the base of the robot are critical steps in the installation process. Utilizing laser alignment tools can significantly enhance the accuracy of this process, reducing the risk of misalignment and the subsequent wear or damage.

Moreover, when selecting replacement gears and pulleys, it is advisable to adhere to the OEM’s specifications or consult with experts like Illinois Pulley & Gear for custom solutions. This ensures compatibility and optimal performance of the industrial robot. Training personnel on the correct operation and maintenance procedures is also essential to prevent misuse or mishandling, which could lead to equipment failure or accidents.

Gears and pulleys play a pivotal role in the functionality and efficiency of industrial machines. Their importance extends beyond mere components; they are the heart of industrial robots, driving innovation, productivity, and safety in the manufacturing sector. Through diligent care, regular maintenance, and adherence to safety guidelines, the longevity and performance of these machines can be significantly enhanced. As the adoption of industrial robots continues to grow, understanding and implementing best practices in the maintenance and safe use of gears and pulleys will be crucial for manufacturers worldwide.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]