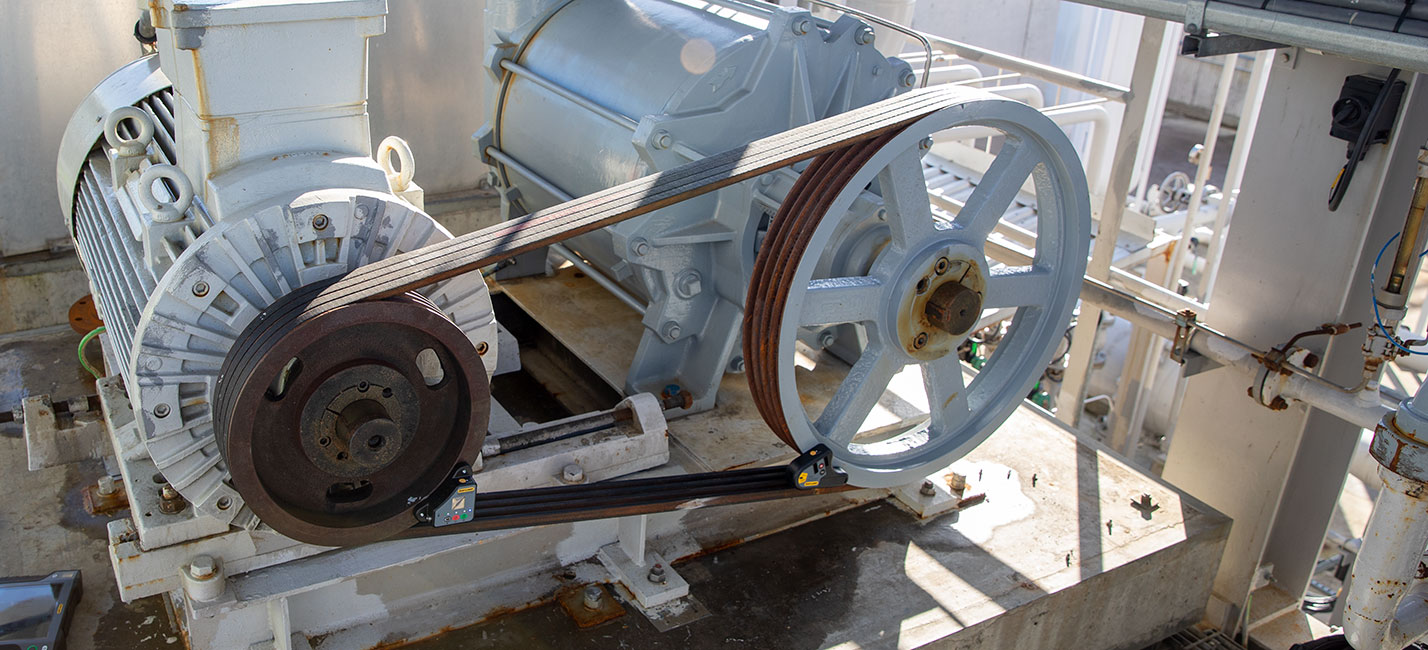

Pulleys are an essential component in many mechanical systems, and they rely on belts to transmit power from the driving pulley to the driven pulley. The right belt on pulley ensures that power is transmitted efficiently and reliably. Choosing the right belt for a pulley system can be a daunting task, but it is essential to avoid premature failure and ensure optimal performance.

Here are some guidelines to help you choose the right belt for your pulley system:

- Determine the type of pulley: The first step in choosing the right belt for your pulley is to identify the type of pulley. There are different types of pulleys such as V-belt, timing belt, and flat belt pulleys, and each requires a different type of belt. It is important to select the correct type of belt for your pulley to ensure that it can handle the load and speed requirements.

- Measure the pulley: Once you have identified the type of pulley, the next step is to measure the pulley’s dimensions accurately. The pulley’s pitch diameter, groove width, and groove depth are critical dimensions that must be measured to ensure the right belt fit. You can use a caliper or a measuring tape to get accurate measurements.

- Calculate the belt length: Once you have measured the pulley dimensions, you can calculate the belt length required for your application. The belt length calculation is a critical step in selecting the right belt for your pulley system. The length of the belt must be such that it provides adequate tension to prevent slippage and ensure that power is transmitted efficiently.

- Determine the belt type: The next step is to determine the type of belt needed for your application. Belts come in different materials such as rubber, polyurethane, and neoprene. The type of belt you choose depends on the load, speed, and environmental conditions of your application. For example, polyurethane belts are best suited for high-speed applications, while rubber belts are ideal for applications that require flexibility.

- Consider the belt width: The width of the belt is also an essential factor to consider when selecting the right belt for your pulley system. The width of the belt must match the pulley’s groove width to ensure optimal performance. A belt that is too narrow will cause excessive wear, while a belt that is too wide will not fit into the pulley groove.

- Choose the right manufacturer: Choosing the right manufacturer is also essential when selecting the right belt for your pulley system. A reputable manufacturer will provide high-quality belts that are designed to handle the load and speed requirements of your application. Always select a manufacturer that has a proven track record of producing reliable belts.

In conclusion, selecting the right belt for your pulley system is essential to ensure that power is transmitted efficiently and reliably. By following the guidelines above, you can choose the right belt for your application and avoid premature failure. Always remember to measure accurately, calculate the belt length, choose the right belt type, consider the belt width, and choose a reputable manufacturer.

CONTINUE READING

Related Posts

Power Transmission Efficiency Customized V-belt pulleys are essential in meeting the specific requirements of different agricultural applications. The design and […]

Industrial gears are a crucial component of various manufacturing and processing systems. When selecting industrial gears, two key factors to […]

Agriculture is a crucial sector that feeds the world and drives economic growth. As the demand for food increases, farmers […]