Taper lock bushes are essential components used to securely attach pulleys, gears, and other mechanical elements to shafts. Their design allows for easy installation and removal, making them a popular choice in various industrial applications. This guide outlines the steps for installing and removing taper lock bushes, ensuring that users can achieve optimal performance and longevity from their machinery.

Understanding Taper Lock Bushes

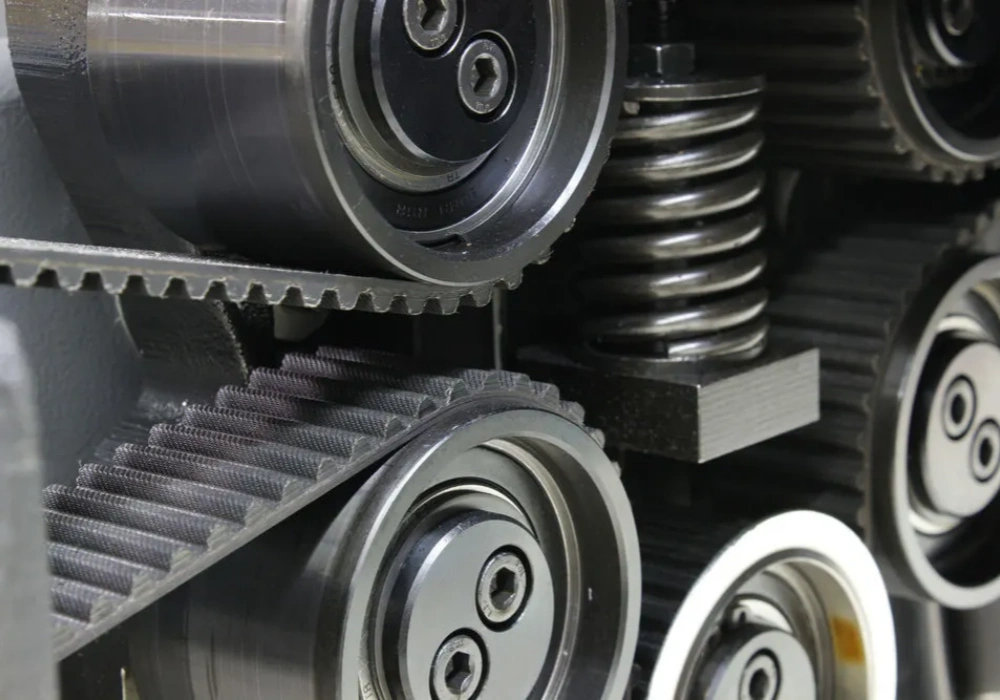

Taper lock bushes consist of a tapered inner bore and a corresponding outer surface that fits snugly into the driven component. This design creates a strong mechanical connection between the shaft and the component, ensuring efficient power transmission. Taper lock bushes are widely used in applications such as conveyor systems, motors, and industrial machinery.

Tools Required for Installation and Removal

Before starting the installation or removal process, ensure you have the following tools on hand:

- Taper lock bush

- Compatible pulley or gear

- Set screws or bolts

- Torque wrench

- Hammer

- Screwdriver

- Cleaning materials (cloth or brush)

Installing a Taper Lock Bush

Preparation: Begin by cleaning the shaft and the inner bore of the taper lock bush. Remove any dirt, rust, or debris to ensure a smooth fit.

Align the Components: Position the taper lock bush over the shaft. Ensure that the taper lock bush is aligned properly with the corresponding component (e.g., pulley or gear).

Insert the Bush: Gently slide the taper lock bush onto the shaft. Tap it lightly with a hammer if necessary, ensuring it fits snugly against the shoulder of the shaft.

Secure the Bush: Once the bush is in place, position the pulley or gear onto the taper lock bush. Align the set screws or bolts with the pre-drilled holes on the bush.

Tighten the Screws: Using a torque wrench, tighten the set screws or bolts to the manufacturer’s specifications. This ensures a secure connection between the bush and the component.

Final Checks: After installation, check for any misalignment or excessive play. Make adjustments as needed to ensure everything is properly seated.

Removing a Taper Lock Bush

Loosen the Screws: Start by loosening the set screws or bolts that secure the taper lock bush to the component. Use a screwdriver or appropriate tool to turn them counterclockwise.

Tap the Component: Once the screws are loosened, gently tap the component (pulley or gear) with a hammer. This action will help to free the bush from its seating.

Slide the Bush Off: Carefully slide the taper lock bush off the shaft. If it resists, you may need to repeat the tapping process or use a puller tool for assistance.

Clean the Shaft: After removing the bush, clean the shaft to remove any residual debris or dirt that may affect future installations.

Inspect for Wear: Examine the taper lock bush and the component for any signs of wear or damage. This inspection ensures that replacements can be made promptly if necessary.

Best Practices for Taper Lock Bush Maintenance

To maximize the lifespan and performance of taper lock bushes, consider the following best practices:

Regular Inspections: Periodically check the condition of the taper lock bushes and associated components. Look for signs of wear, looseness, or misalignment.

Proper Lubrication: Ensure that all moving parts are properly lubricated to minimize friction and wear during operation.

Follow Manufacturer Guidelines: Always adhere to the manufacturer’s recommendations for installation, removal, and maintenance. This ensures optimal performance and reduces the risk of failure.

Taper lock bushes are integral components in many mechanical systems, providing a reliable and efficient connection between shafts and driven components. By following the outlined steps for installation and removal, users can ensure that these bushes function effectively, leading to enhanced machinery performance and longevity. Regular maintenance and inspections will further contribute to the durability of taper lock bushes, making them a valuable choice in industrial applications.

CONTINUE READING

Related Posts

In the world of belts, two common types are the cogged belt and the V belt. Each type has its […]

Machining is a precision manufacturing process that involves removing material to create a desired part or component. The success of […]

V-pulley, also known as V-belt drive, is a common type of belt drive system that is widely used in various […]