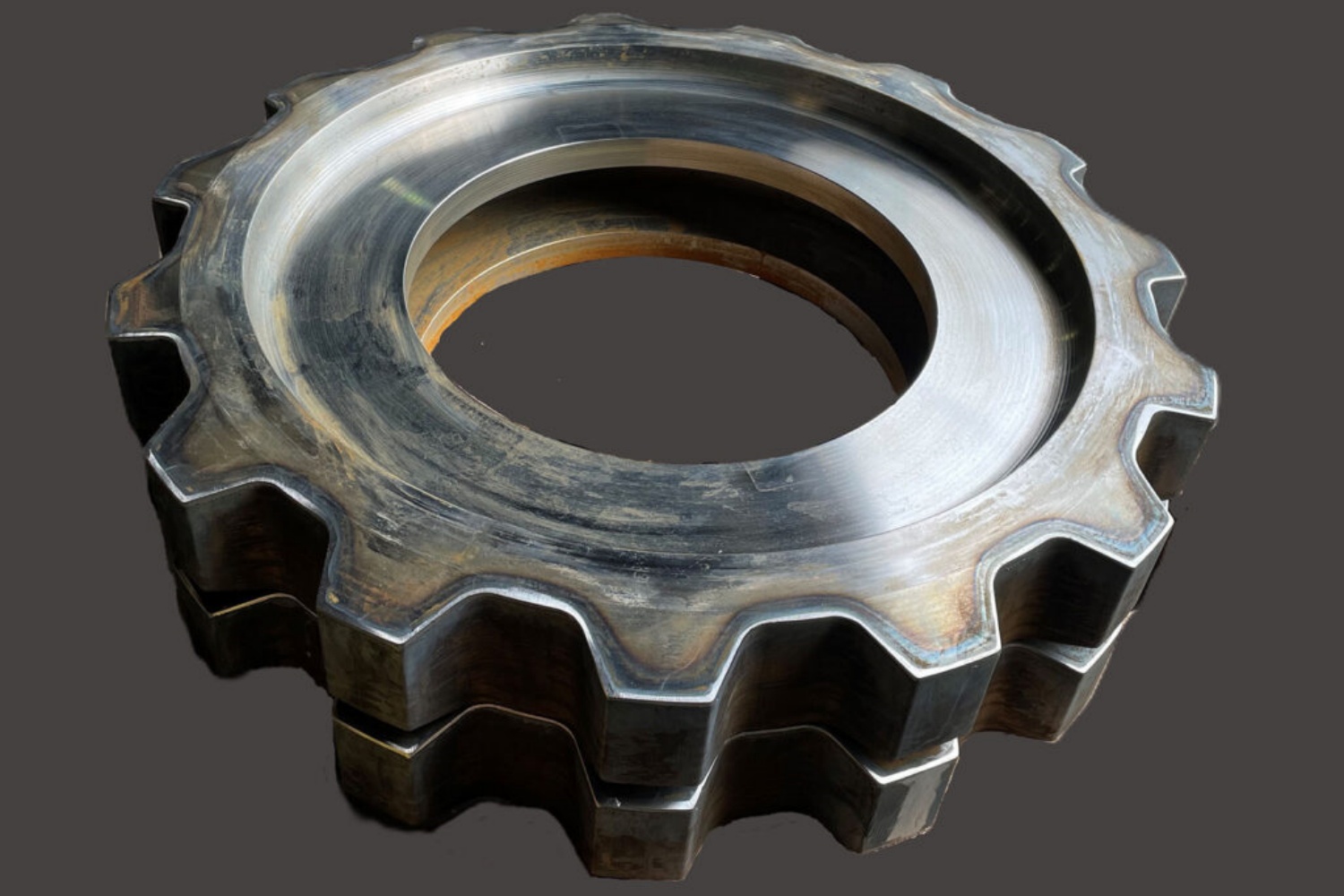

In mechanical transmission, sprockets ,v-pulley ,taper bush ,gear shaft, chain couplings ,gears are the most common and efficient transmission components. Here we introduce how many types of gear are the most common ones in this area?

Spur gears :Transmit power through parallel shafts. The teeth of the spur gear are parallel to the axis, which makes the gear to generate a radial reaction load on the shaft, rather than an axial load. Spur gears operate with a single line of contact between the teeth, so they tend to be noisier than helical gears. Spur gears break out of contact with one tooth and accelerate into contact with the next when the teeth roll in mesh, while the helical gears transmit torque more smoothly with more than one tooth in contact.

Helical gears are designed similar as spur gears and can be used to drive parallel or non-parallel/non-intersecting shafts. Additionally, the helical teeth are oriented at an angle, which makes multiple teeth to be in contact with one another at any given time, thus having a quieter and smoother operation.

Double Helical Gears / Herringbone Gears:

Herringbone gears are basically two helical gears glued together side by side with their teeth having opposite directions. This arrangement is designed to eliminate the thrust created in the single helical gear by making the loads cancel each other out. However, the cost of this type of gears is high because they are difficult to manufacture with the required precision.

Bevel gears :Running on intersecting axes, especially at 90 degrees, bevel gears are similar as helical gears, whose teeth are designed at an angle, thus making multiple teeth contact at the same time. All bevel gears are conical, but a variety of different bevel gears are available including: spiral bevel gears, straight bevel gears and crown bevel gears.

Worm gears:Usually consisting of a helical gear and a circular gear, worm gears are in pairs, and they run smoothly and quietly, as well as generate a lot of friction. In addition, worm gears are only available in non-parallel/non-intersecting shaft configurations and are ideal for high shock load applications.

Hypoid Gears:Hypoid gears are very similar to spiral bevel gears, with the main difference being that their axes of rotation do not coincide. Therefore, the design of teeth otherwise placed on hyperbolic conical parts must be made very carefully with regard to their angles. Often being used in applications where speed reduction/increase is required, hypoid gears are often found in vehicle drivetrains, where allowing for a more compact implementation, as the pinion does not have to be above the hypoid gear, but on the side of it.

Rack and pinion gears:Consisting of spur gears and racks, rack and pinion gears are also in pairs and are used in parallel axis configurations. This kind of design leads to generate high friction and stress.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]