In the world of mechanical engineering, the importance of power transmission components cannot be overstated. Among these, V-pulleys play a critical role in ensuring the smooth and efficient operation of machinery. Oris V-pulleys, renowned for their precision engineering and robust design, have become a staple in various industrial applications.

Understanding V-Pulleys

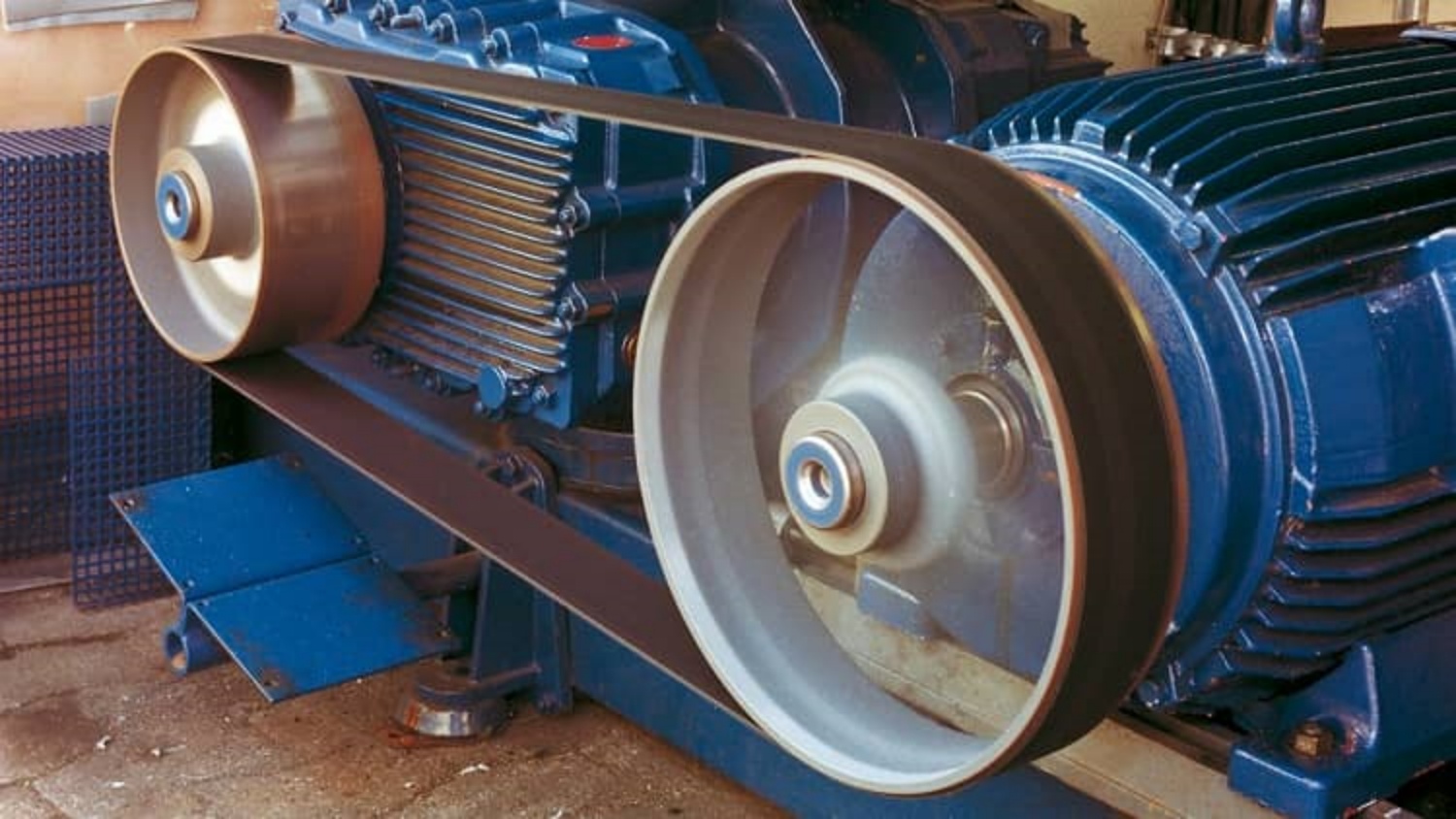

V-pulleys, also known as V-belt pulleys, are components used in belt drive systems where they transfer rotational motion from one shaft to another. The “V” in V-pulleys refers to the shape of the grooves in which the V-belt sits. These grooves are designed to provide a secure grip on the belt, minimizing slippage and maximizing the transfer of power. V-pulleys are widely used in applications ranging from automotive engines to industrial machinery due to their efficiency and reliability.

The Design Excellence of Oris V-Pulleys

Oris V-pulleys are distinguished by their meticulous design and superior materials. The key design features of Oris V-pulleys that contribute to improved machinery performance include:

Precision Machining

Oris V-pulleys are manufactured with high precision to ensure a perfect fit with V-belts. This precision machining reduces the chances of misalignment, which can cause wear and tear on both the pulley and the belt. A well-aligned pulley system operates more smoothly and with less friction, leading to enhanced efficiency and longer component life.

High-Quality Materials

The choice of materials in Oris V-pulleys is critical to their performance. Typically made from durable metals such as cast iron, steel, or aluminum, these pulleys are designed to withstand high levels of stress and strain. The use of high-quality materials ensures that Oris V-pulleys are resistant to wear and corrosion, which is essential for maintaining consistent performance over time.

Optimal Groove Design

The grooves in Oris V-pulleys are engineered to match the specific profile of V-belts perfectly. This optimal groove design enhances the grip on the belt, reducing slippage and ensuring efficient power transmission. The precise fit between the belt and the pulley groove is crucial for maintaining the tension and preventing the belt from slipping off during operation.

How Oris V-Pulleys Enhance Machinery Performance

The technical design features of Oris V-pulleys translate directly into several performance benefits for machinery. Here are some of the key ways in which these pulleys improve the efficiency and reliability of mechanical systems:

Improved Power Transmission Efficiency

One of the primary advantages of using Oris V-pulleys is their ability to transmit power more efficiently. The precise fit and high-quality materials reduce friction losses, ensuring that more of the input power is transferred to the driven component. This improved efficiency can lead to significant energy savings, especially in large-scale industrial applications.

Reduced Maintenance Requirements

The durability and wear resistance of Oris V-pulleys mean that they require less frequent maintenance compared to lower-quality alternatives. The high-quality materials resist corrosion and wear, reducing the need for regular replacements. Additionally, the precision engineering minimizes the risk of misalignment and slippage, which can cause excessive wear on belts and pulleys.

Enhanced Reliability and Longevity

Oris V-pulleys are designed to withstand harsh operating conditions, making them highly reliable components in mechanical systems. Their robust construction ensures that they can handle high loads and stresses without deforming or failing. This reliability translates into longer service life for both the pulleys and the belts, reducing downtime and increasing overall productivity.

Versatility in Applications

The versatility of Oris V-pulleys allows them to be used in a wide range of applications, from automotive engines to heavy industrial machinery. Their ability to handle different types of V-belts and adapt to various power transmission requirements makes them a versatile choice for engineers looking to optimize machinery performance.

Smooth Operation and Reduced Vibration

The precise machining and optimal groove design of Oris V-pulleys contribute to smoother operation and reduced vibration in mechanical systems. Reduced vibration not only enhances the performance and longevity of the machinery but also contributes to a quieter and more comfortable working environment. This is particularly important in applications where noise and vibration can affect the quality of work or the comfort of operators.

Case Studies and Real-World Applications

To illustrate the impact of Oris V-pulleys on machinery performance, consider the following real-world applications:

Industrial Conveyor Systems

In industrial conveyor systems, the efficiency and reliability of power transmission components are crucial for maintaining smooth and uninterrupted operation. Oris V-pulleys, with their high precision and durability, ensure that the conveyor belts run smoothly with minimal slippage and wear. This reduces downtime and maintenance costs, leading to increased productivity and cost savings.

Automotive Engines

In automotive engines, V-pulleys are used to drive various accessories such as the alternator, water pump, and air conditioning compressor. The high-quality materials and precision design of Oris V-pulleys ensure efficient power transmission and reliable operation of these accessories. This contributes to the overall performance and longevity of the engine, enhancing vehicle reliability.

Agricultural Machinery

Agricultural machinery operates in challenging environments, requiring robust and reliable components to handle heavy loads and harsh conditions. Oris V-pulleys, with their wear-resistant materials and optimal design, provide the necessary durability and efficiency for applications such as tractors and harvesters. This ensures that the machinery can operate effectively with minimal maintenance, reducing downtime during critical farming seasons.

Oris V-pulleys are a testament to the advancements in engineering and design that have significantly improved the performance of mechanical systems. Through precision machining, high-quality materials, and optimal groove design, these pulleys offer enhanced power transmission efficiency, reduced maintenance requirements, and increased reliability. Their versatility and ability to deliver smooth operation make them an indispensable component in a wide range of applications, from industrial machinery to automotive engines. By choosing Oris V-pulleys, engineers and machine operators can ensure that their systems run efficiently, reliably, and with minimal downtime, ultimately leading to improved productivity and cost savings.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]