The process of changing a pulley on a lawn mower will depend on the specific make and model of the mower, as well as the type of pulley that needs to be replaced. However, here are some general steps that can be followed to change a pulley on a lawn mower:

- Turn off the mower: Before you begin any work on the mower, make sure that it is turned off and that the spark plug wire is disconnected to prevent accidental starting.

- Locate the pulley that needs to be replaced: The pulley that needs to be replaced may be on the engine, transmission, or blade spindle, depending on the mower. Refer to the owner’s manual to determine the location of the pulley.

- Remove the belt: To remove the pulley, you will need to first remove the belt that is connected to it. This may involve loosening tensioners or removing covers to access the belt.

- Remove the old pulley: Once the belt is removed, use a wrench or socket set to remove the bolts that hold the pulley in place. You may need to use a pulley removal tool to loosen the pulley if it is stuck.

- Install the new pulley: Place the new pulley in the same position as the old one and use the wrench or socket set to tighten the bolts. Make sure that the pulley is properly aligned with the other components.

- Reinstall the belt: After the new pulley is in place, reinstall the belt and adjust the tension as needed. Refer to the owner’s manual for instructions on proper belt tension.

- Test the mower: Once the new pulley is installed and the belt is properly tensioned, start the mower and test it to ensure that it is running smoothly and that the new pulley is working as it should.

It’s important to note that the specific steps for changing a pulley on a lawn mower may vary depending on the make and model of the mower, and that it may be necessary to consult the owner’s manual or seek assistance from a professional if you are unsure about any aspect of the process.

How to make the belt pulley required by the mower ?

- Making a belt pulley for a mower requires a certain level of skill, experience, and specialized equipment. If you have access to a metal lathe and other machining tools, and feel confident in your ability to use them safely and effectively, you may be able to make a pulley for your mower. Here are some general steps that you can follow:

- Determine the specifications of the pulley: Before you start making the pulley, you will need to determine the size, shape, and other specifications required by your mower. These specifications can be found in the owner’s manual or by contacting the manufacturer.

- Choose the right materials: Select a suitable material for the pulley based on the required specifications, such as the size and speed of the pulley. Common materials used for pulleys include cast iron, steel, and aluminum.

- Cut the material to size: Cut the material to the required size using a metal saw or other cutting tool. Be sure to use safety equipment such as goggles and gloves.

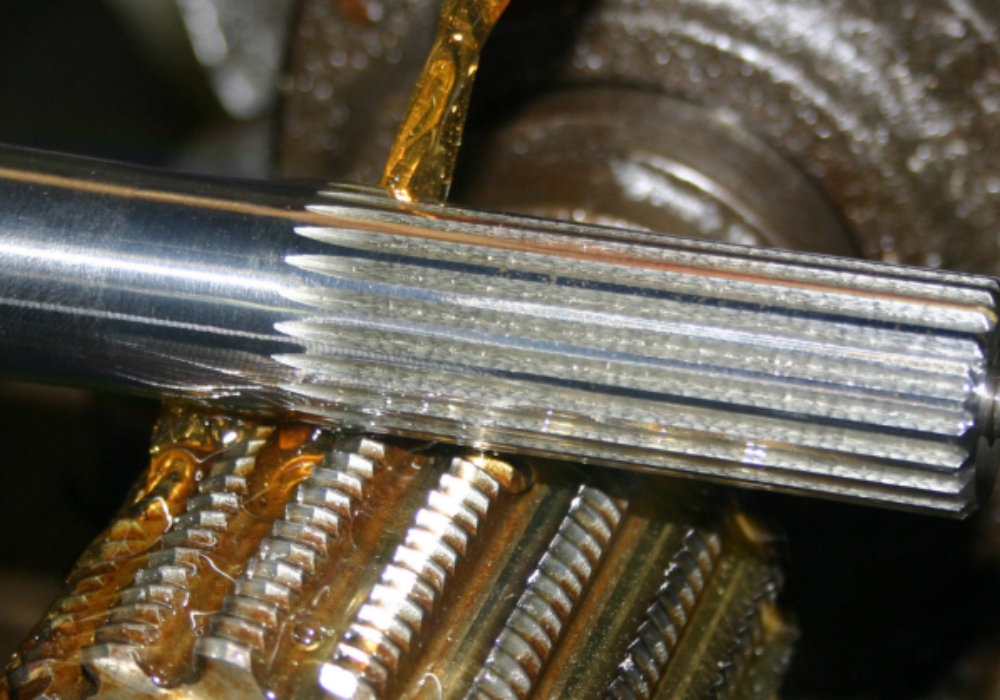

- Turn the pulley on a lathe: Use a metal lathe to turn the pulley to the required specifications. This involves shaping the material by removing excess material until it has the desired shape and size.

- Add keyways: If your mower requires a keyed pulley, you will need to add a keyway to the pulley to allow it to fit onto the shaft. This involves cutting a slot in the pulley to match the size of the key.

- Finish the pulley: Use a file or sandpaper to smooth the edges and surfaces of the pulley. This will ensure that the pulley fits properly and runs smoothly.

It’s important to note that making a pulley requires a certain level of expertise and specialized tools, and that it may be more practical to purchase a replacement pulley rather than attempting to make one yourself. Additionally, modifying or altering a mower can affect its safety and performance, so it’s important to ensure that any modifications are appropriate and in accordance with the manufacturer’s recommendations.

CONTINUE READING

Related Posts

In the world of machinery and mechanical systems, precision is key. Spline shafts play a crucial role in ensuring that […]

Spline shafts are critical components in various machinery and equipment, playing a pivotal role in power transmission and torque distribution. […]

Custom Gears: Where Precision Meets the Unique Demands of Your Industry In the intricate world of machinery and power transmission, […]