Shanghai Oris, a leading manufacturer in China, is well known for its precision-engineered idler sprockets, especially designed for ANSI roller chains.

Understanding the Basics of Idler Sprockets for ANSI Roller Chains

Idler sprockets, an integral part of any chain-driven mechanical system, are unpowered sprockets that guide or tension the chain. The ANSI roller chains, named for the American National Standards Institute that sets the standards for their design, are widely used in various industrial applications. ANSI roller chains rely on high-quality idler sprockets to maintain tension and alignment.

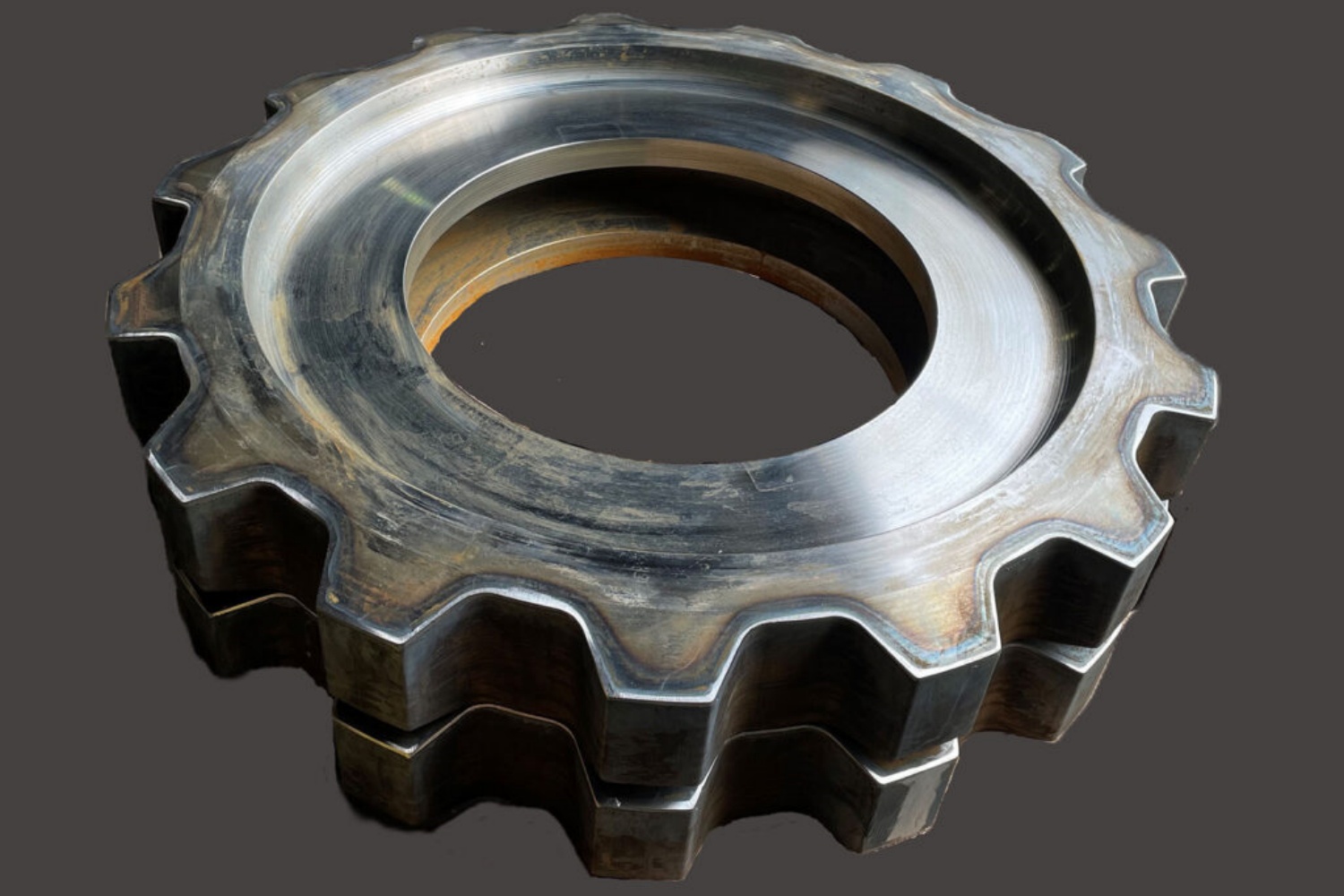

Shanghai Oris manufactures idler sprockets specifically designed for ANSI roller chains. These sprockets are engineered with precision, ensuring that they align perfectly with the chain links to prevent any slipping or skipping. The idler sprockets are typically made from high-strength materials to withstand the pressure exerted by the chain and the load it carries.

The Role of Idler Sprockets in ANSI Roller Chains

The idler sprockets serve two main functions in an ANSI roller chain: tensioning and guiding. As a tensioner, the idler sprocket ensures the chain remains tight, preventing any slack that could lead to inefficient operation or potential system failure. As a guide, the idler sprocket keeps the chain properly aligned with the drive sprocket, maintaining smooth and consistent operation.

A high-quality idler sprocket, such as those produced by Shanghai Oris, can significantly improve the performance of an ANSI roller chain. By ensuring proper tension and alignment, these idler sprockets reduce wear on the chain and other components, thereby increasing overall system efficiency and longevity.

Prolonging the Life of Your Idler Sprockets for ANSI Roller Chains

Maintenance is key to prolonging the lifespan of your idler sprockets. Regular inspection can help identify signs of wear or damage early, allowing for timely replacement or repair. Lubrication is also critical; a well-lubricated idler sprocket reduces friction, preventing overheating and wear.

Moreover, using high-quality idler sprockets, such as those manufactured by Shanghai Oris, can contribute significantly to extending the sprocket’s lifespan. These sprockets are designed with durability in mind, using robust materials and precise manufacturing techniques to ensure they can withstand the rigors of heavy-duty operation.

Idler sprockets for ANSI roller chains play a crucial role in enhancing the efficiency and longevity of chain-driven systems. As a trusted manufacturer, Shanghai Oris is committed to providing high-quality idler sprockets that meet the demanding standards of the industry. By understanding the role and maintenance needs of these components, users can significantly improve the lifespan and performance of their systems.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]