Industrial gears play a pivotal role in the operational efficiency and productivity of various industries. These components, often housed within industrial gearboxes, are fundamental in translating engine power into usable force, thereby driving the machinery that is at the heart of industrial processes. This article delves into the formation, differences, advantages, and the significant roles industrial gears fulfill across different sectors.

Formation and Differences

Industrial gears are meticulously designed and manufactured to meet the rigorous demands of various industrial applications. The formation of these gears involves selecting appropriate materials and engineering designs that can withstand high torque, extreme temperatures, and continuous operation. Materials such as cast iron, steel, and aluminum are commonly used, each offering distinct advantages in terms of strength, durability, and resistance to wear and tear.

The differences among industrial gears primarily lie in their design and functionality. For instance, bevel gears are used to change the axis of rotation, which is crucial in machinery that requires a change in direction of power transmission. Helical gears, on the other hand, are designed to operate more smoothly and quietly, making them suitable for high-speed applications. The choice of gear depends on the specific requirements of the machinery and the industry it serves.

Advantages of Industrial Gears

Industrial gears offer several advantages that make them indispensable in various sectors. Firstly, they provide the ability to adjust torque and speed, enabling machinery to operate more efficiently and effectively. This adaptability is crucial in industries where precision and control over machinery speed are necessary for quality production.

Moreover, the durability and reliability of industrial gears ensure that machinery can operate under harsh conditions without frequent breakdowns. This reduces downtime and maintenance costs, thereby increasing overall productivity. Additionally, the versatility of gear designs allows for their use in a wide range of applications, from simple conveyor belts to complex manufacturing processes.

Role and Significance in Different Industries

The Paper Industry

In the paper industry, industrial gears are essential for running the machinery involved in production processes. The demand for paper products continues to grow, necessitating efficient and reliable gearboxes to drive the equipment that produces, cuts, and finishes paper goods. The variety of gearboxes used, including those made of different materials, ensures that the machinery can meet the specific demands of paper production.

The Cement Industry

The cement industry relies heavily on industrial gears, especially in high torque situations. With the anticipated growth in infrastructure projects, the demand for cement and, consequently, for industrial gearboxes is expected to rise. Gearboxes in this sector are tasked with altering torque to the maximum extent possible, ensuring that the machinery used in cement processing operates efficiently.

The Sugar and Steel Industries

Both the sugar and steel industries depend on a broad range of industrial machinery, which in turn relies on various types of gearboxes. These industries require gearboxes that can handle a wide range of torque and ratio capacities (sugar industry) and those that are strong, durable, and capable of enduring high temperatures (steel industry). The use of helical, spur, and bevel gearboxes in these sectors underscores the importance of industrial gears in maintaining operational efficiency and productivity.

Industrial gears and gearboxes are crucial components that significantly impact the efficiency, productivity, and reliability of machinery across various industries. Their ability to adapt torque and speed, coupled with their durability and versatility, makes them indispensable in the modern industrial landscape. As industries continue to evolve and expand, the role and significance of industrial gears are set to become even more pronounced, driving innovation and efficiency in industrial processes.

CONTINUE READING

Related Posts

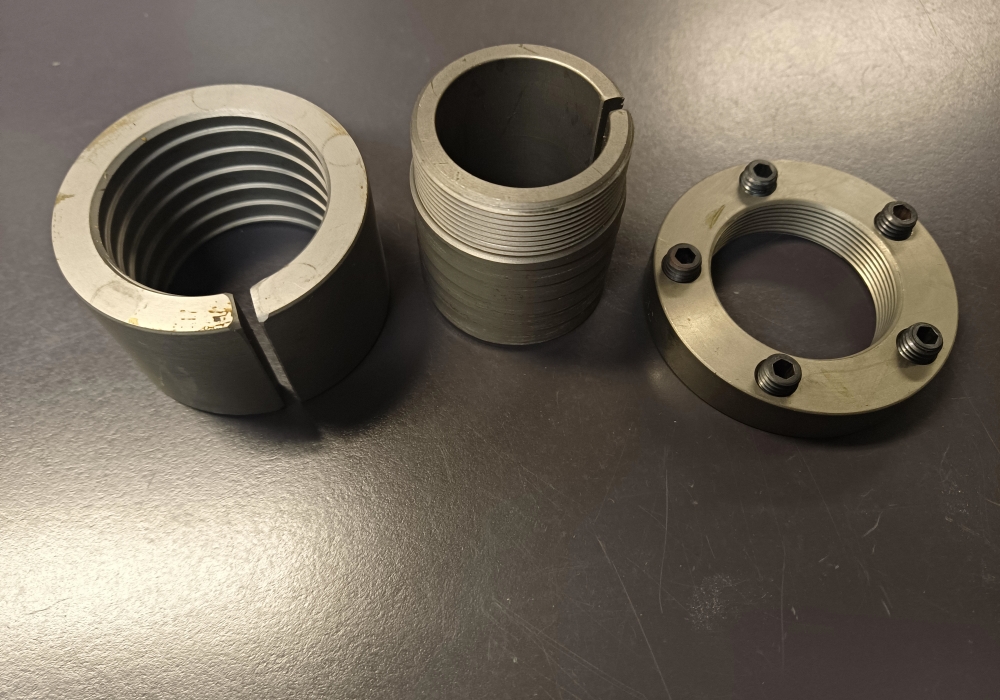

When it comes to connecting components on a shaft, two popular choices are Taper Lock Bushes and Keyed Bushings. These […]

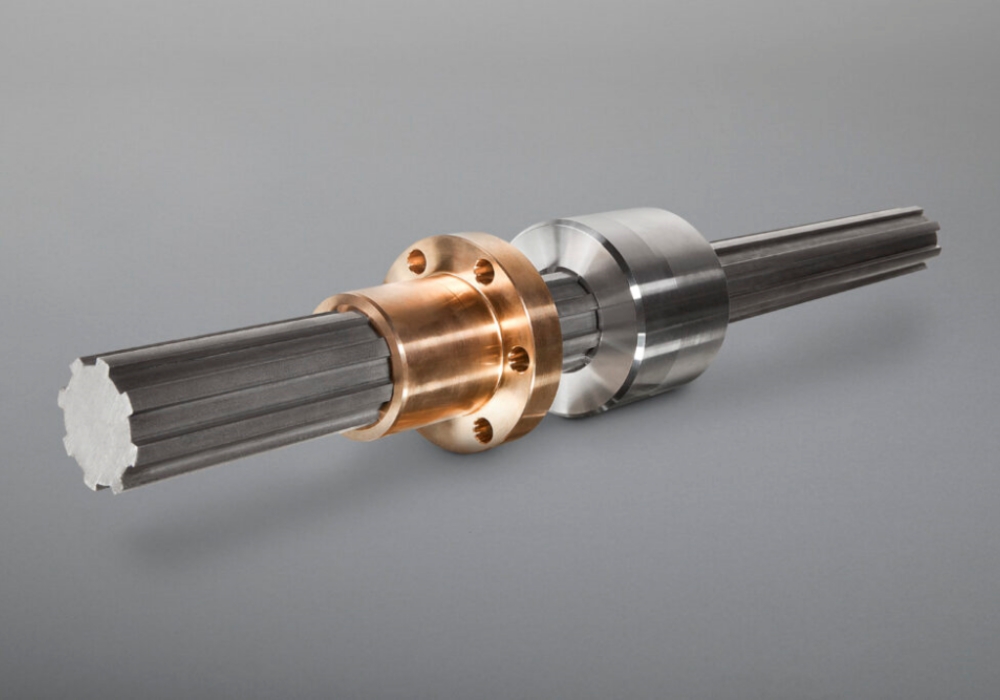

Spline shafts are essential components in various mechanical systems, providing the means to transmit torque and motion with precision. To […]

When it comes to transmitting torque and motion in machinery, the choice between spline shafts and keyed shafts is a […]