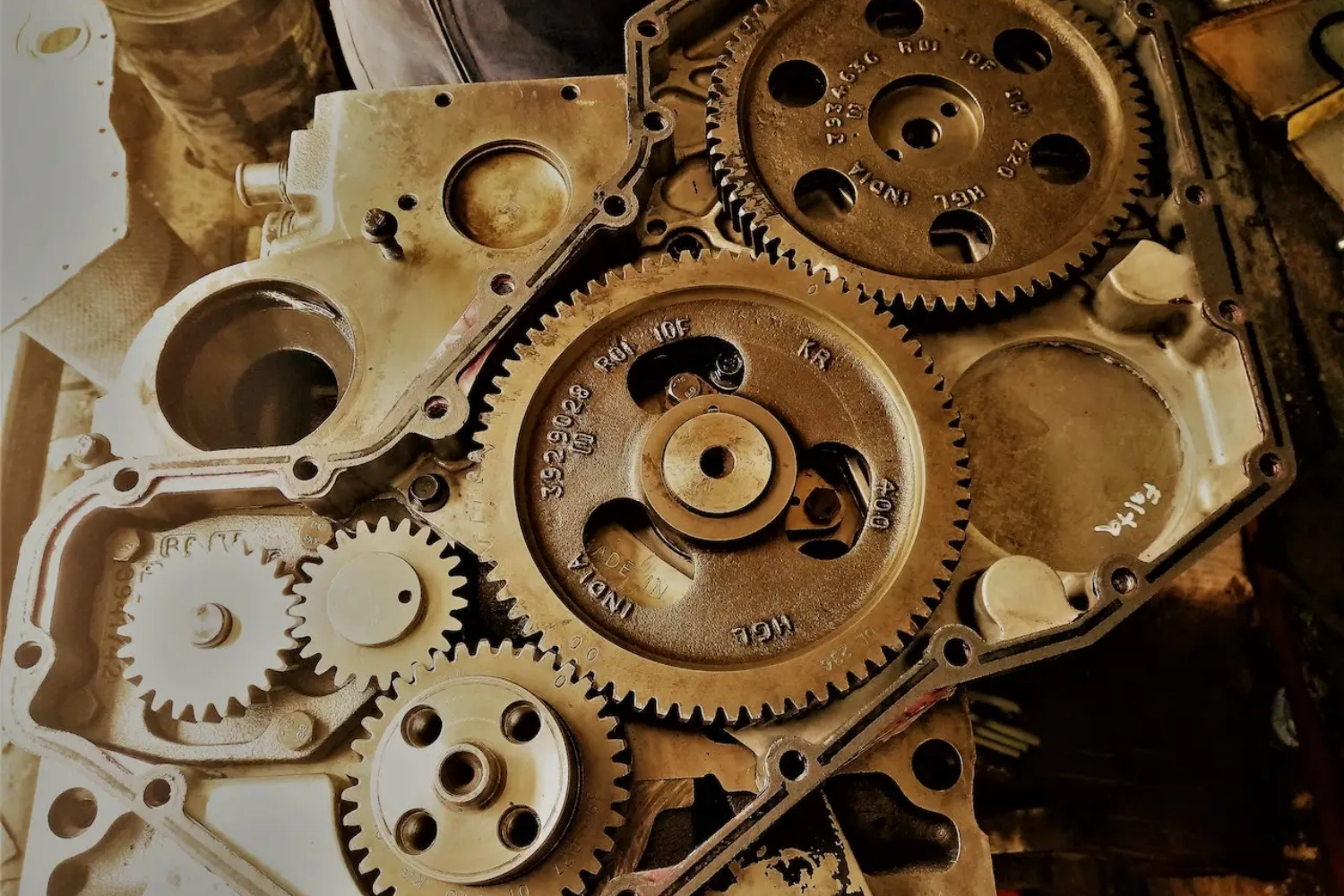

In the intricate machinery of today’s industrial landscape, the silent heroes driving precision and reliability are industrial spur gears. Oris, a beacon of excellence in gear manufacturing, stands at the forefront, wielding industrial prowess to craft spur gears that transcend the ordinary, meeting the unique demands across diverse applications.

At the heart of countless industrial processes, spur gears play a pivotal role in transmitting power smoothly and efficiently. Oris, a distinguished name in the world of gear manufacturing, has carved a niche for itself by seamlessly blending innovation, precision engineering, and a commitment to excellence in crafting industrial spur gears.

Crafting Precision:

Oris’ journey begins with an unwavering commitment to precision engineering. Crafting industrial spur gears demands a meticulous understanding of the application’s requirements. Each gear is meticulously designed to endure specific loads, speeds, and environmental conditions. This commitment to precision ensures that every gear meets and exceeds industry standards.

Materials Mastery:

The selection of materials is a cornerstone of Oris’ industrial prowess. Understanding that different applications demand distinct material properties, Oris navigates the delicate balance between strength, durability, and weight. From traditional steel alloys to cutting-edge composite materials, the material selection process contributes to the gears’ resilience and performance.

Advanced Manufacturing Techniques:

In the realm of industrial spur gear manufacturing, precision is synonymous with advanced techniques. Oris leverages state-of-the-art manufacturing technologies, including CNC machining, gear hobbing, and precision grinding, to shape each tooth with unparalleled accuracy. These advanced techniques result in gears that boast not only flawless performance but also extended operational lifespans.

Application Diversification:

Oris’ industrial prowess extends beyond the workshop floor to diverse applications. Whether in automotive systems, heavy machinery, or aerospace components, the versatility of Oris-crafted industrial spur gears is a testament to their commitment to meeting the unique demands of various industries. Case studies highlighting successful gear applications provide tangible evidence of Oris’ impact.

Quality Assurance Excellence:

Ensuring the reliability of industrial spur gears is a non-negotiable aspect of Oris’ commitment to excellence. Rigorous quality assurance measures, including dimensional checks, material analysis, and performance testing, are integral steps in guaranteeing that each gear leaving the Oris workshop is a paragon of quality.

Innovation as a Driving Force:

Oris doesn’t merely meet industry standards; it surpasses them through continuous innovation. The integration of cutting-edge technologies, such as simulation software and advanced coating applications, ensures that Oris-crafted industrial spur gears not only meet but anticipate the evolving needs of modern industries.

Environmental Responsibility:

In the era of sustainable manufacturing, Oris stands as a responsible industrial player. From material sourcing to waste reduction initiatives, Oris is committed to minimizing its environmental footprint. This commitment aligns with the broader industry trend towards eco-friendly practices.

As industries evolve and machinery becomes more sophisticated, the role of industrial spur gears in ensuring seamless power transmission cannot be overstated. Oris, with its unwavering dedication to precision, materials mastery, and innovation, has etched its mark in the industrial gear landscape. The impact of Oris’ industrial prowess resonates across diverse applications, making it a trusted name synonymous with reliability, performance, and excellence in crafting industrial spur gears.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]