Industrial pulleys are an integral part of the machinery that powers the modern world. From manufacturing plants to construction sites, these pulleys ensure the smooth operation of equipment that needs to transmit force and motion. The editor will introduce beginners to the world of industrial pulleys, explaining their types, applications and how they contribute to complex mechanical systems.

Understanding Industrial Pulleys

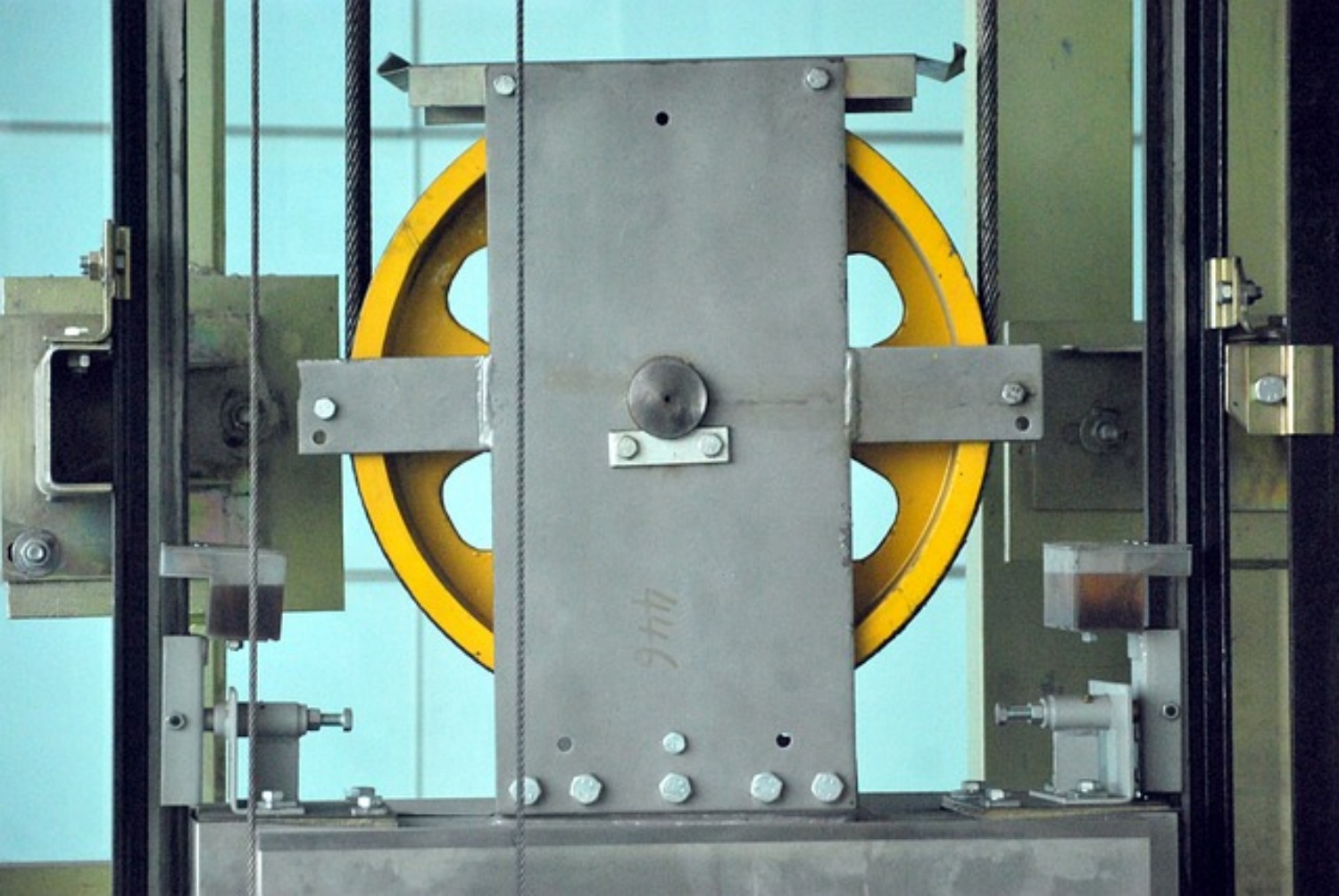

At its essence, an industrial pulley is a wheel on an axle or shaft designed to support the movement and change the direction of a force through a rope or belt. What sets industrial pulleys apart from their simpler counterparts is their robust construction, precision engineering, and the ability to handle heavy loads and transmit significant power across systems.

Types of Industrial Pulleys

Industrial pulleys come in various types, each suited to specific applications and operational requirements:

- Fixed Pulleys: These pulleys are mounted on a fixed axle and primarily change the direction of the force applied. While simple, they are essential in industrial settings for guiding cables and belts along a predetermined path.

- Movable Pulleys: Attached directly to the load, movable pulleys offer a mechanical advantage by distributing the load’s weight across multiple sections of the rope or belt, reducing the force needed to lift or move the load.

- Compound Pulleys: Combining fixed and movable pulleys, compound systems significantly reduce the effort required to move heavy loads. They are the backbone of many industrial machines, providing flexibility and efficiency in operations.

- Timing Pulleys: These are designed to synchronize movements within a system, ensuring precise alignment and timing between different parts. Timing pulleys are crucial in applications where accurate mechanical timing is necessary, such as in automated assembly lines.

Applications in Industry

Industrial pulleys are ubiquitous in the manufacturing and construction industries, among others. Their applications range from lifting heavy materials to transmitting power across machinery:

- Conveyor Systems: Pulleys are used to drive conveyor belts, moving goods and materials efficiently through manufacturing and packaging processes.

- Cranes and Hoists: In construction, pulleys are part of the lifting mechanisms that move materials to great heights, playing a critical role in building infrastructure.

- Automotive Systems: Timing pulleys in automotive engines ensure that the timing belt operates smoothly, maintaining the engine’s performance and longevity.

- Material Handling Equipment: Forklifts, elevators, and other material handling devices rely on pulleys to lift and transport heavy loads within warehouses and distribution centers.

Selecting the Right Pulley

Choosing the appropriate industrial pulley involves considering several factors, including the load weight, the type of movement required (linear or rotational), and the environmental conditions (such as exposure to chemicals or extreme temperatures). Material selection—whether metal, plastic, or composite—also plays a crucial role in the pulley’s durability and performance.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of industrial pulleys. Regular inspections can identify wear and tear, misalignment, or lubrication issues before they lead to system failures. Additionally, understanding the operational limits of pulleys and the systems they integrate with is crucial for maintaining a safe working environment.

Industrial pulleys are more than just simple mechanical devices; they are vital components that drive the complex machinery essential to various industries. For beginners entering the field of mechanical engineering or industrial design, gaining a solid understanding of pulleys is a step toward mastering the mechanics behind modern industrial operations. As we navigate through the complexities of industrial pulleys, we unlock the potential to innovate and improve the efficiency and safety of industrial systems worldwide.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]