In mechanical design, the corresponding technical knowledge is essential to design, the mechanical elements, gears. This is also suitable even if you choose to use gears that are already designed.

The gear knowledge that needs to be mastered includes various calculation formulas used in gear strength calculation and size calculation, gear types, gear technical terms, speed ratio and rotation direction of gear pair, tooth shape and thickness, backlash, ISO and AGMA standards related to accuracy grades, gear assembly accuracy, gear material and heat treatment, gear hardness, lubrication problems when using gears, countermeasures for problems like noise and damage, etc., geometric tolerances used in gear drawing and special geometric symbols used in mechanical drawing.

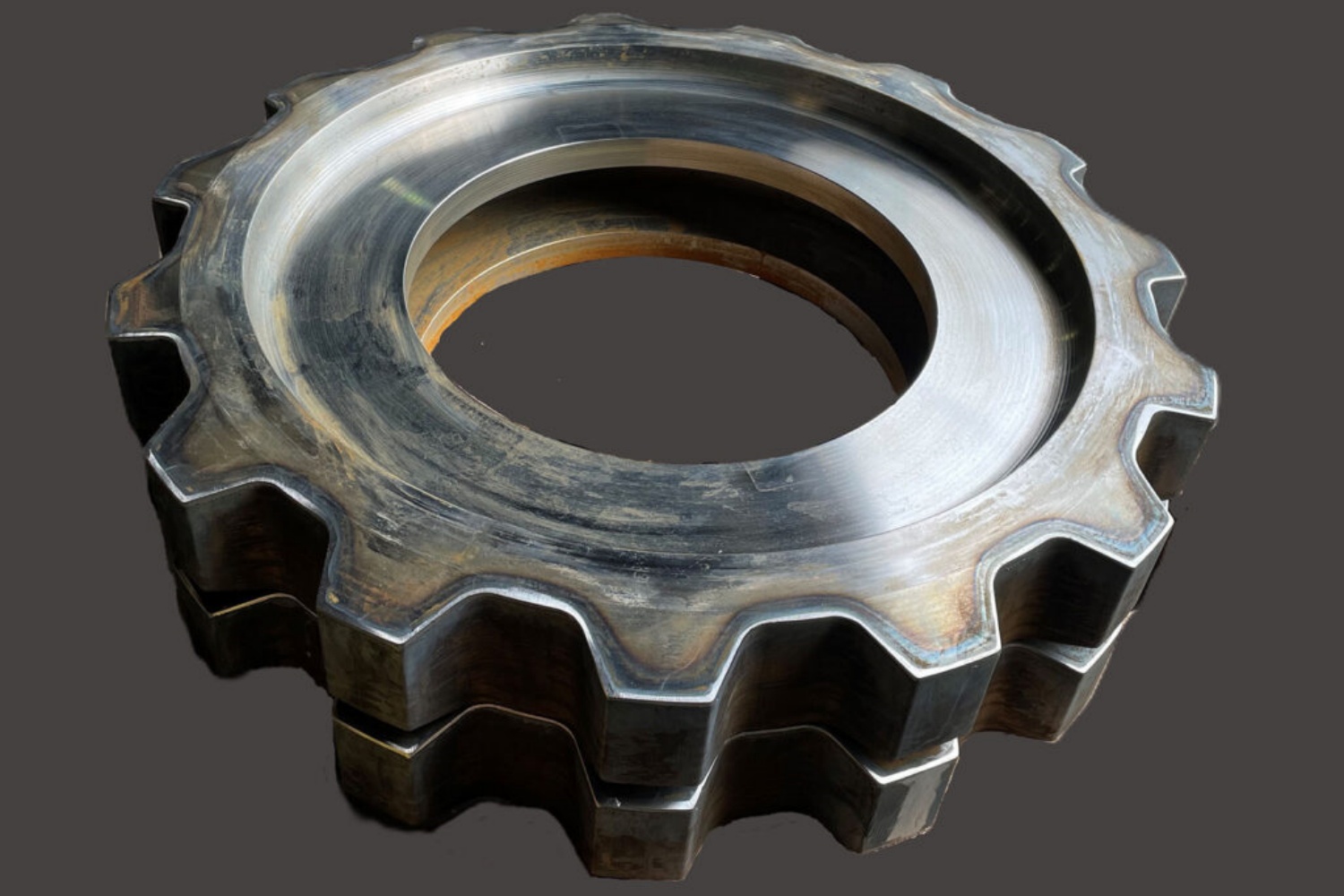

Gears are mechanical parts that must be used in pairs to function. The combination of the two can change the transmission direction and speed, with conveying the rotational force or rotational motion.

1. Using spur gears and helical gears to transfer rotation and power between two parallel shafts.

2. Change rotary motion to linear motion. In addition, it can also be used reversely to change from linear motion to rotary motion, which can be used in conjunction with spur gears and racks, or helical gears and helical racks.

3. When the rotation and power are transmitted between the two intersecting axes, the angle between the two intersecting axes is generally 90 degrees, and a conical bevel gear or an arc bevel gear can be used.

The angle between the two shafts is 90 degrees, and the staggered shaft helical gears or worm gears can be used when transmitting rotation and power between two shafts that neither intersect nor parallel.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]