In the intricate dance of machinery and mechanical systems, certain components operate quietly but play an indispensable role. Among these unsung heroes, industrial sprockets stand as essential elements that power a myriad of industrial applications.

The Backbone of Machinery

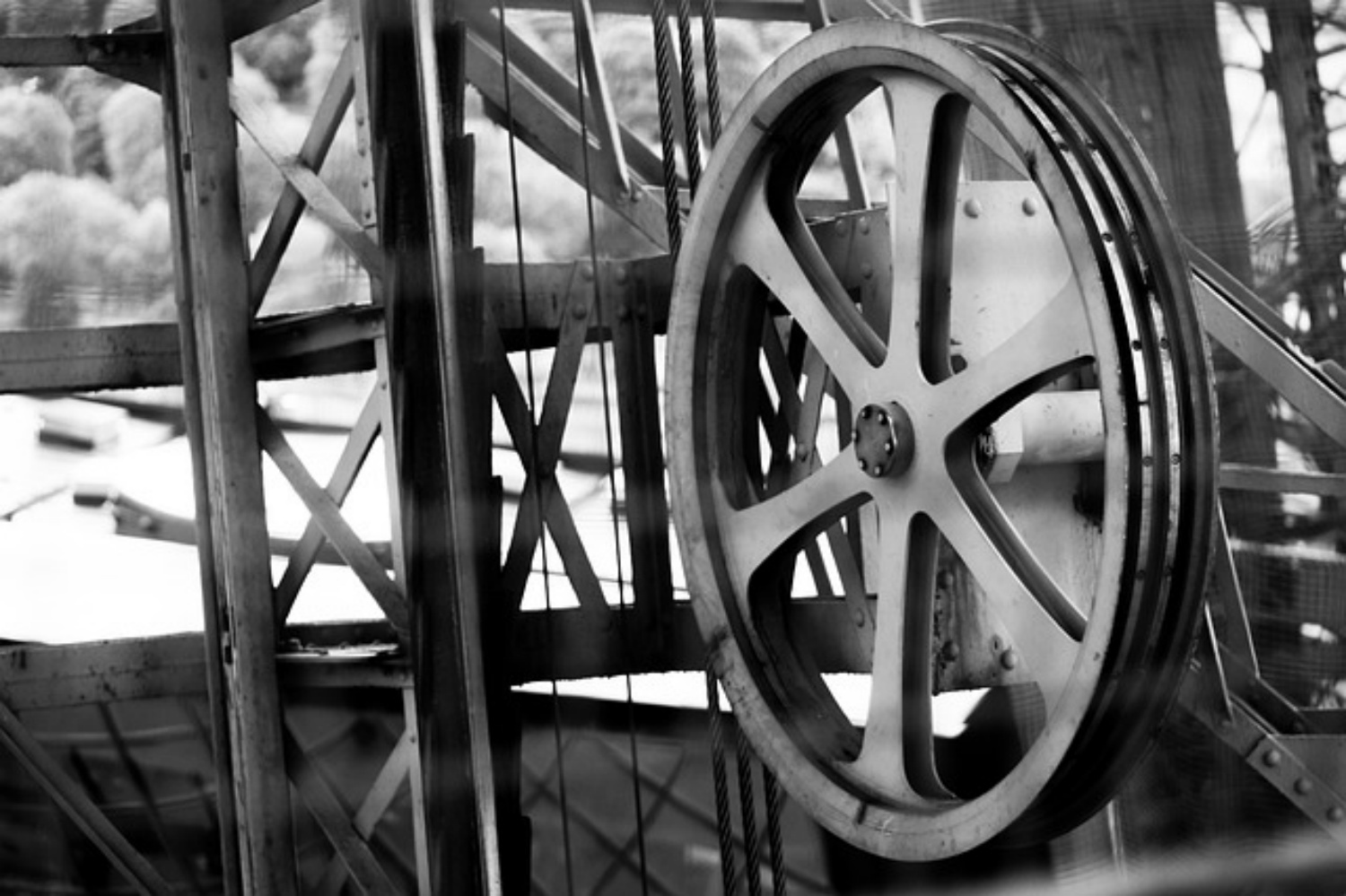

Industrial sprockets, often inconspicuous yet vital, serve as the backbone of various machinery, particularly in power transmission systems. They are fundamental in converting rotational motion between shafts, ensuring smooth and efficient operation in a multitude of industries, from manufacturing plants to agricultural equipment.

Essential Link in Power Transmission

At their core, industrial sprockets facilitate motion and power transmission through the use of chains or belts. By meshing with these transmission elements, sprockets enable the transfer of torque from one rotating shaft to another, facilitating the seamless movement of equipment and machinery.

Customized Configurations for Varied Needs

The versatility of industrial sprockets lies in their ability to be customized to suit specific applications. They come in a diverse range of sizes, tooth configurations, materials, and designs. Whether it’s high-speed conveyor systems, heavy-duty manufacturing machinery, or precision-based equipment, sprockets can be tailored to meet the unique demands of different industries.

Critical Role in Precision and Efficiency

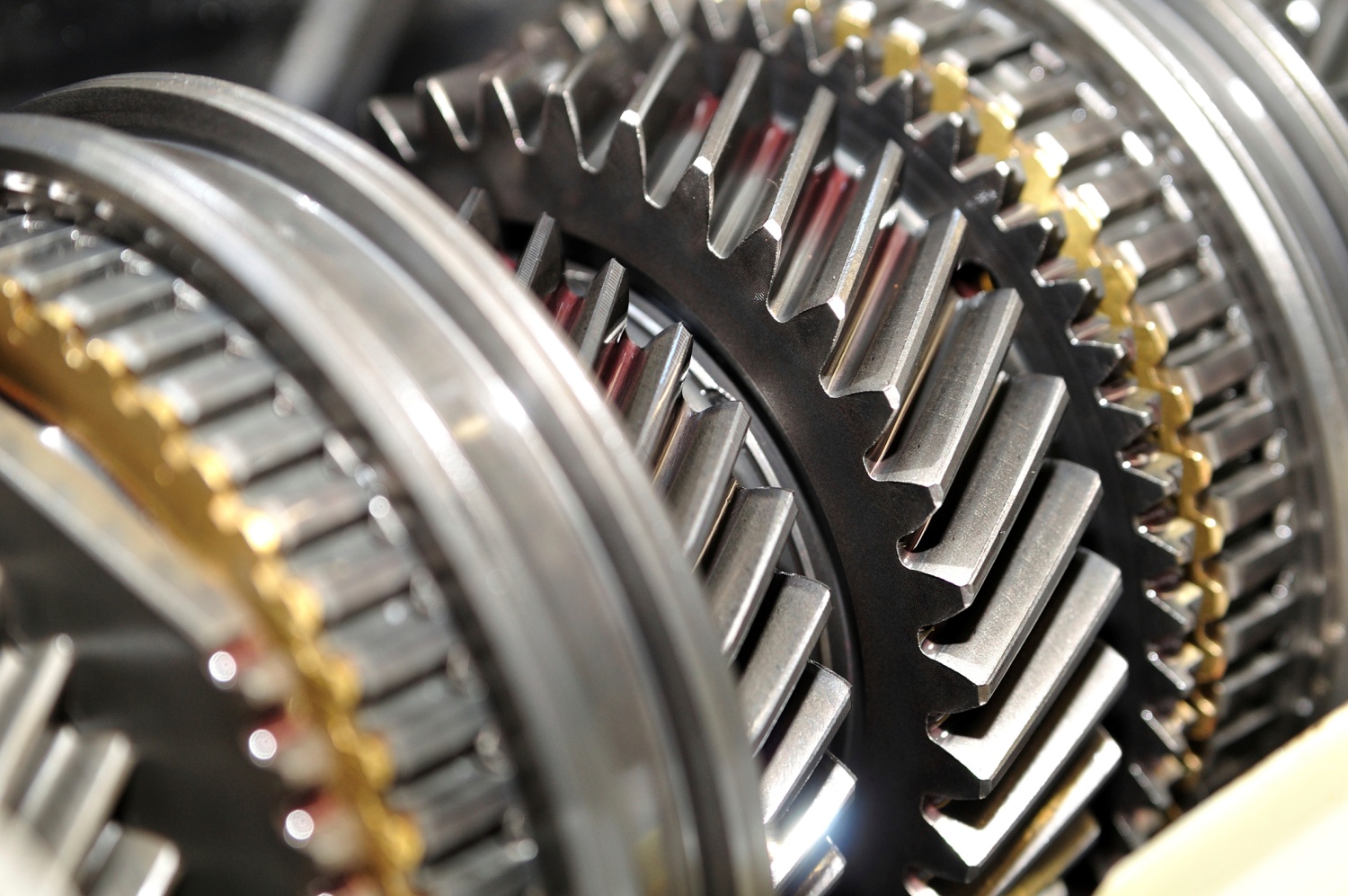

The precision engineering of industrial sprockets is paramount. Their accurately shaped teeth ensure a secure and efficient engagement with chains or belts, minimizing slippage and maintaining consistent power transmission. This precision contributes significantly to the overall efficiency and reliability of machinery, reducing wear and tear while optimizing performance.

Enduring Durability

Industrial sprockets are crafted from robust materials such as hardened steel, alloy steel, or stainless steel, offering durability and resilience to challenging operating conditions. Their sturdy construction allows them to withstand high loads, harsh environments, and prolonged usage, ensuring longevity and minimal maintenance requirements.

Silent Contributors to Operational Success

Often operating behind the scenes, industrial sprockets play a crucial role in ensuring the smooth functioning of machinery. Their reliability directly impacts production efficiency, reducing downtime and enhancing overall productivity. Despite their humble appearance, the absence or malfunction of sprockets can significantly disrupt industrial operations.

Industrial sprockets may not garner the spotlight, but their significance in the seamless operation of machinery across diverse industries cannot be overstated. They stand as silent heroes, driving efficiency, precision, and reliability in the industrial landscape, underscoring their indispensability in the realm of modern machinery.

More:Understanding the Design and Application of 1 Bore V Belt Pulleys

CONTINUE READING

Related Posts

Spur gears, the most straightforward and prevalent type of cylindrical gears, play a pivotal role in the world of machinery. […]

The agricultural sector has always been a cornerstone of human civilization, providing the necessary resources for survival and prosperity. As […]

Industrial pulleys are an integral part of the machinery that powers the modern world. From manufacturing plants to construction sites, […]