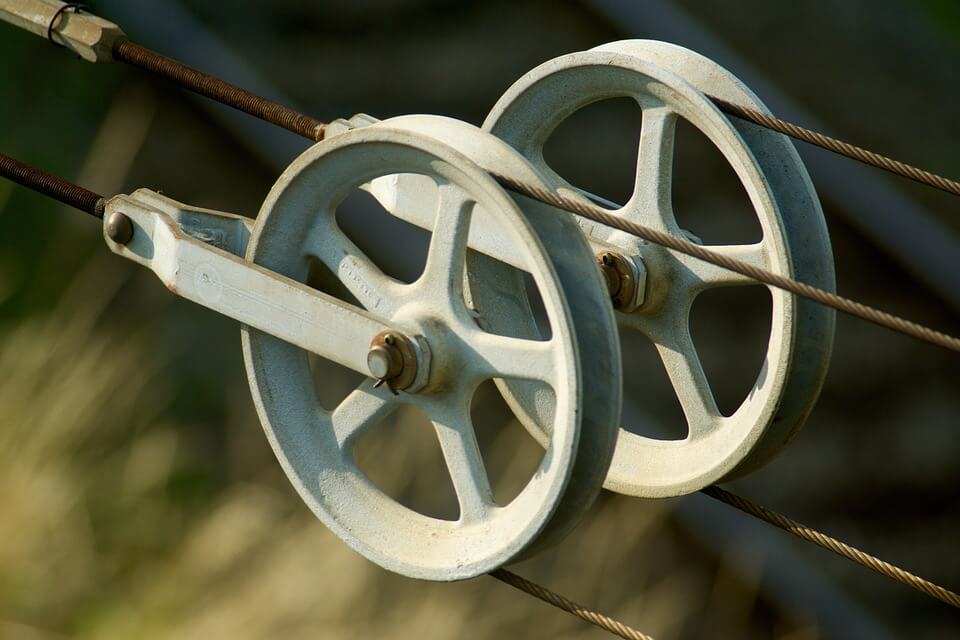

Pulleys play an important role in the power transmission process of various machines and devices. Among them, main drive pulleys, also known as primary pulleys, are particularly significant as they transmit power from the source to the driven component. These pulleys are designed to rotate at a constant speed and transfer torque from the motor to the driven equipment via a belt. In this article, we will discuss the advantages and benefits of using main drive pulleys in various applications.

Increased Efficiency

Main drive pulleys play a crucial role in ensuring maximum power transmission efficiency. They provide a smooth and consistent speed of rotation, which reduces the wear and tear on the belt and pulley system, as well as on other mechanical components. Moreover, the use of high-quality materials in main drive pulleys can help reduce friction and energy loss, leading to a more efficient power transmission system overall.

Improved Control

Main drive pulleys offer precise control over the speed and torque of the driven equipment. By adjusting the diameter of the pulley, the speed of the driven component can be easily controlled. Additionally, variable speed pulleys can be used to vary the speed of the driven equipment based on the changing requirements of the application. This level of control can help improve the efficiency and accuracy of many machines and processes.

Reduced Maintenance

Main drive pulleys are designed for maximum durability and longevity. They are often made of high-quality materials such as steel or aluminum, which can withstand the stress and strain of heavy-duty operations. By using a properly sized and designed main drive pulley, the load on the belt and other components is reduced, which can help extend their lifespan and reduce the need for maintenance or replacement.

Flexibility in Design

Main drive pulleys are available in a wide range of designs, sizes, and configurations, making them adaptable to different applications and environments. They can be customized to suit specific torque and speed requirements, as well as to fit into tight spaces or unusual layouts. Additionally, main drive pulleys can be used in conjunction with other pulleys to create a complex power transmission system.

Cost-Effective Solution

Main drive pulleys are often a cost-effective solution for many applications. They can be easily replaced if damaged or worn, and do not require complex installation or maintenance procedures. Additionally, the use of a main drive pulley can help reduce energy consumption and increase the lifespan of other mechanical components, leading to cost savings over time.

In conclusion, main drive pulleys are an essential component in many power transmission systems, providing increased efficiency, improved control, reduced maintenance, flexibility in design, and cost-effective solutions. By understanding the advantages and benefits of main drive pulleys, engineers and operators can make informed decisions when selecting and implementing power transmission systems for their applications.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]