Variable pitch V-belt pulleys are an essential part of power transmission systems. They are designed to regulate the speed of rotating equipment by changing the effective diameter of the pulley. This article will discuss the construction, working principle, benefits, and applications of variable pitch V-belt pulleys.

Construction of Variable Pitch V-Belt Pulleys:

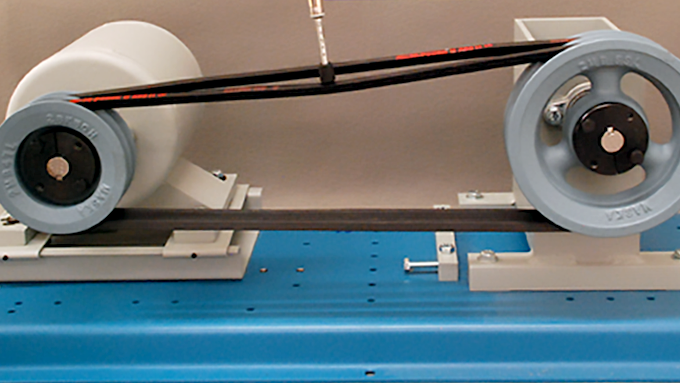

Variable pitch V-belt pulleys consist of two main components: the sheave and the hub. The sheave is the circular disk that is mounted on the motor shaft and receives the V-belt. The hub is the central part of the pulley that is bolted to the motor shaft. The sheave and the hub are connected by a taper lock bushing or a keyway.

The sheave of a variable pitch V-belt pulley is designed with two or more rows of V-grooves with varying diameters. The grooves are positioned at different angles to each other, allowing for the effective diameter of the pulley to change as the belt moves from one groove to another.

Working Principle of Variable Pitch V-Belt Pulleys:

Variable pitch V-belt pulleys work by changing the effective diameter of the pulley. This is achieved by moving the V-belt from one groove to another on the sheave. When the belt is in the smallest groove, the effective diameter of the pulley is the smallest, and the motor runs at the highest speed. When the belt moves to the larger grooves, the effective diameter of the pulley increases, and the motor speed decreases.

The pitch of the V-belt determines the distance between the centers of the V-grooves on the sheave. As the pitch of the V-belt changes, the effective diameter of the pulley also changes, allowing for precise speed control.

Benefits of Variable Pitch V-Belt Pulleys:

Speed Regulation: Variable pitch V-belt pulleys allow for precise speed regulation of rotating equipment. This makes them ideal for applications where speed control is critical, such as in HVAC systems, conveyor systems, and power transmission systems.

Energy Efficiency: By regulating the speed of rotating equipment, variable pitch V-belt pulleys help to improve energy efficiency. This is because the motor runs at the optimal speed, reducing energy consumption and prolonging the life of the motor.

Longer Belt Life: The ability to change the effective diameter of the pulley means that the belt experiences less wear and tear. This extends the life of the belt, reducing the frequency of belt replacement and maintenance costs.

Applications of Variable Pitch V-Belt Pulleys:

Variable pitch V-belt pulleys are used in a wide range of industrial applications, including:

HVAC Systems: Variable pitch V-belt pulleys are used in HVAC systems to regulate the speed of fans and blowers, improving energy efficiency and reducing noise levels.

Conveyor Systems: Conveyor systems require precise speed control to transport materials efficiently. Variable pitch V-belt pulleys are used in conveyor systems to regulate the speed of the motor, ensuring that the conveyor runs at the optimal speed.

Power Transmission Systems: Variable pitch V-belt pulleys are used in power transmission systems to regulate the speed of rotating equipment, such as pumps, compressors, and generators.

Conclusion:

Variable pitch V-belt pulleys are an important component of power transmission systems. They allow for precise speed regulation, improve energy efficiency, and extend the life of the belt. Their ability to change the effective diameter of the pulley makes them ideal for a wide range of industrial applications, including HVAC systems, conveyor systems, and power transmission systems. By understanding the construction, working principle, benefits, and applications of variable pitch V-belt pulleys, engineers can design efficient and reliable power transmission systems.

CONTINUE READING

Related Posts

In industrial machinery, V-groove pulleys are a critical component, transferring power efficiently and ensuring the smooth operation of various mechanical […]

Spur gears are among the simplest and most widely used gears in mechanical engineering and industrial applications. Their straightforward design […]

Taper lock bushes are essential components used to securely attach pulleys, gears, and other mechanical elements to shafts. Their design […]