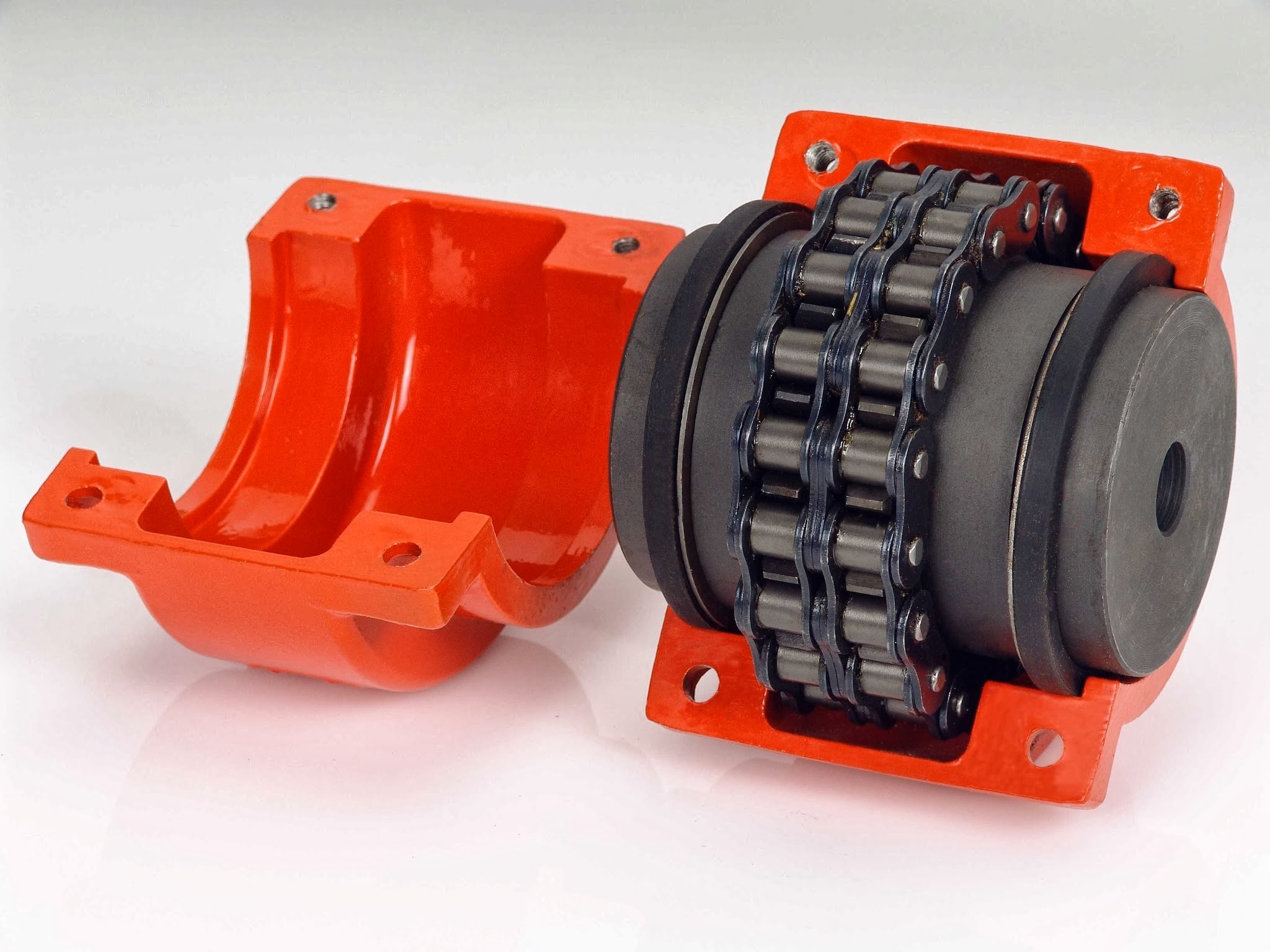

In the dynamic landscape of modern manufacturing, the efficient transfer of power is integral to the seamless operation of industrial machinery. Chain couplings, known for their robustness and reliability, play a critical role in ensuring the smooth transmission of power between various mechanical components. This article delves into the profound impact of chain coupling efficiency in manufacturing processes, highlighting its significance, benefits, and the pivotal role it plays in maximizing power transfer for enhanced industrial productivity and performance.

1. Ensuring Seamless Power Transmission

At the core of the manufacturing process lies the need for seamless power transmission to drive the various stages of production. Chain couplings facilitate this essential function by efficiently transmitting power from the driving to the driven components, ensuring a continuous and uninterrupted flow of energy throughout the machinery. By minimizing energy losses and maximizing power transfer efficiency, chain couplings contribute significantly to the overall productivity and operational reliability of the manufacturing process.

2. Robust and Reliable Power Transfer Mechanism

The robust construction and design of chain couplings enable them to withstand heavy loads, high torques, and demanding operational conditions commonly encountered in manufacturing environments. Their ability to effectively manage the transmission of substantial power ensures that the machinery operates with resilience and reliability, thereby minimizing the risk of operational disruptions and downtime. This robust and reliable power transfer mechanism forms the backbone of the manufacturing process, empowering industrial operations to proceed smoothly and consistently.

3. Customization for Specific Industrial Applications

The versatility of chain couplings extends to their customization capabilities, allowing for tailored solutions that cater to the specific power transmission requirements of diverse manufacturing processes. Whether it involves accommodating varying torque capacities, adjusting the coupling size, or modifying the chain configuration, customized chain coupling solutions are designed to align precisely with the unique demands of specific industrial applications. This customization ensures that the chain couplings seamlessly integrate within the machinery, facilitating optimized power transmission and operational efficiency.

4. Maintenance Economy and Durability

Efficient power transmission is closely intertwined with effective maintenance practices and operational longevity. Chain couplings, renowned for their durability and minimal maintenance requirements, contribute to the overall economy of the manufacturing process. Their robust construction and low maintenance characteristics reduce the need for frequent repairs or replacements, thereby minimizing operational costs and ensuring that the manufacturing process continues uninterrupted. This emphasis on maintenance economy and durability underscores the pivotal role of chain couplings in sustaining efficient and cost-effective industrial operations.

5. Resilience in Challenging Manufacturing Environments

The manufacturing environment often presents challenging conditions, including high temperatures, heavy vibrations, and exposure to various contaminants. Chain couplings, engineered to withstand such harsh operating conditions, exhibit exceptional resilience and performance, ensuring that the power transmission remains consistent and reliable. Their resilience in adverse environments minimizes the risk of premature wear and tear, contributing to extended equipment lifespan and enhanced operational sustainability in the manufacturing sector.

6. Precision Power Transfer Control

Precision control over power transmission is critical in maintaining operational stability and product quality within the manufacturing process. Chain couplings, designed with precision power transfer control mechanisms, enable industrial manufacturers to regulate the power flow with meticulous accuracy. By fine-tuning the power transmission parameters, including torque, speed, and rotational alignment, chain couplings facilitate precise control over the production process, ensuring that the manufactured products meet the required specifications and quality standards.

7. Facilitating Machinery Interconnection and Synchronization

Modern manufacturing processes often involve the interconnection and synchronization of multiple machinery components to achieve seamless production workflows. Chain couplings serve as the pivotal link in facilitating the coordination and synchronization of various machinery elements, allowing for smooth and integrated manufacturing operations. Their ability to connect diverse mechanical components and synchronize their movements enhances the overall efficiency and productivity of the manufacturing process, enabling streamlined and synchronized production cycles.

8. Contributing to Energy Efficiency and Sustainability

Efficient power transmission is synonymous with energy efficiency and sustainability in the manufacturing sector. Chain couplings, by ensuring that power is transmitted with minimal energy losses, contribute to the overall energy efficiency of the production process. Their role in optimizing power transfer and minimizing energy wastage aligns with the principles of sustainable manufacturing, fostering environmentally responsible industrial practices and reducing the carbon footprint associated with energy-intensive manufacturing operations.

9. Overcoming Manufacturing Challenges with Reliable Power Transmission

Manufacturing processes often encounter various challenges, including heavy loads, sudden torque fluctuations, and demanding operational dynamics. Chain couplings, equipped to handle these challenges with their robust design and reliable power transmission capabilities, enable industrial manufacturers to overcome these obstacles seamlessly. By providing stable and consistent power transmission, chain couplings empower manufacturing processes to operate efficiently, even under demanding and challenging manufacturing conditions.

10. Integrating Advanced Technologies for Enhanced Power Transmission

As manufacturing technology continues to evolve, chain couplings have evolved to integrate seamlessly with advanced technologies, including automation, digital control systems, and Industry 4.0 solutions. Their compatibility with these advanced technological platforms enhances their power transmission capabilities, allowing for real-time monitoring, predictive maintenance, and remote control functionalities. The integration of advanced technologies with chain couplings revolutionizes the power transmission landscape, paving the way for smart and connected manufacturing processes that are efficient, adaptive, and responsive to the dynamic demands of modern industrial production.

The impact of chain coupling efficiency in manufacturing processes is multi-dimensional, encompassing seamless power transmission, robust reliability, customization for diverse applications, maintenance economy, resilience in challenging environments, precision power transfer control, machinery interconnection, energy efficiency, and technological integration. By serving as the cornerstone of efficient power transmission in the manufacturing sector, chain couplings uphold the reliability, sustainability, and productivity of industrial operations, positioning themselves as indispensable components in the machinery landscape that drive operational success and manufacturing excellence.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]