Motor pulleys play a crucial role in the operation of many types of machinery, from electric motors to internal combustion engines. They work by transferring power from the motor shaft to a driven component, such as a belt, chain, or gear. There are various types of motor pulleys available, each with its own unique design and application. In this article, we will explore the different types of motor pulleys, their functions, and tips for maintaining them.

Types of Motor Pulleys

- V-belt pulleys: These are the most common type of motor pulley and are used to transfer power from the motor to a V-belt. They have a V-shaped groove in the center of the pulley that matches the V-shaped cross-section of the belt.

- Timing belt pulleys: These pulleys are designed to work with a timing belt, which has teeth that mesh with the grooves of the pulley. Timing belt pulleys are used in applications where precise timing is required, such as in automotive engines and industrial machinery.

- Flat belt pulleys: As the name suggests, these pulleys are designed to work with flat belts. They have a flat surface that comes into contact with the belt, providing the necessary friction to transfer power.

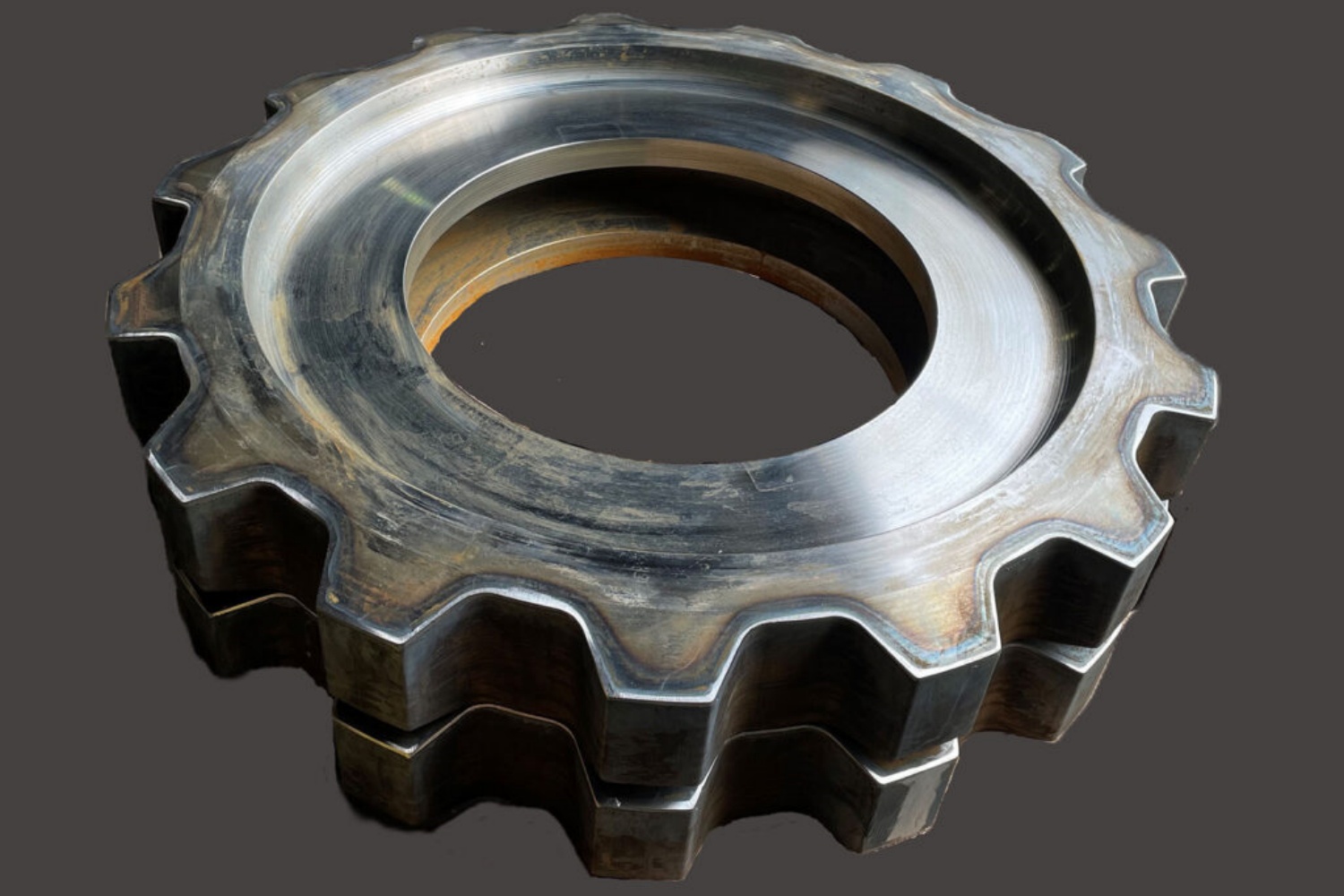

- Chain pulleys: These pulleys work with a chain rather than a belt. They have teeth on the outside of the pulley that mesh with the links of the chain, providing a positive drive.

Functions of Motor Pulleys

Motor pulleys serve several important functions in machinery:

- Transferring power: The primary function of a motor pulley is to transfer power from the motor to a driven component, such as a belt, chain, or gear.

- Increasing or decreasing speed: Motor pulleys can be used to increase or decrease the speed of a driven component. This is achieved by using pulleys of different sizes, which change the ratio of the pulley system.

- Providing torque: In addition to transferring power, motor pulleys can also provide torque to the driven component. This is important in applications where a high amount of torque is required, such as in heavy machinery.

Maintenance Tips for Motor Pulleys

Proper maintenance is essential for ensuring the longevity and optimal performance of motor pulleys. Here are some tips for maintaining motor pulleys:

- Regular cleaning: Motor pulleys should be cleaned regularly to remove any dirt or debris that can accumulate on the surface. This can be done using a soft brush or cloth.

- Lubrication: Proper lubrication is critical for the smooth operation of motor pulleys. Make sure to use the right type of lubricant for the specific type of pulley and application.

- Belt tension: The tension of the belt or chain is important for the proper functioning of motor pulleys. Make sure to adjust the tension according to the manufacturer’s specifications.

- Inspect for wear: Check the pulleys regularly for signs of wear or damage, such as cracks or grooves. Replace any worn or damaged pulleys as soon as possible to prevent further damage to the system.

Conclusion

Motor pulleys are essential components of many types of machinery, and proper maintenance is critical for their optimal performance and longevity. By understanding the different types of motor pulleys and their functions, as well as implementing proper maintenance procedures, you can ensure that your machinery operates smoothly and efficiently. Remember to always consult the manufacturer’s recommendations and seek professional help when necessary.

CONTINUE READING

Related Posts

In the dynamic landscape of mechanical engineering, spline shafts have played a pivotal role in power transmission and motion control. […]

In the world of industrial machinery, sprockets play a critical role in the efficiency, performance, and durability of various equipment. […]

Conveyor sprockets are vital in material handling systems, driving the chains and belts that transport products across various industries. In […]