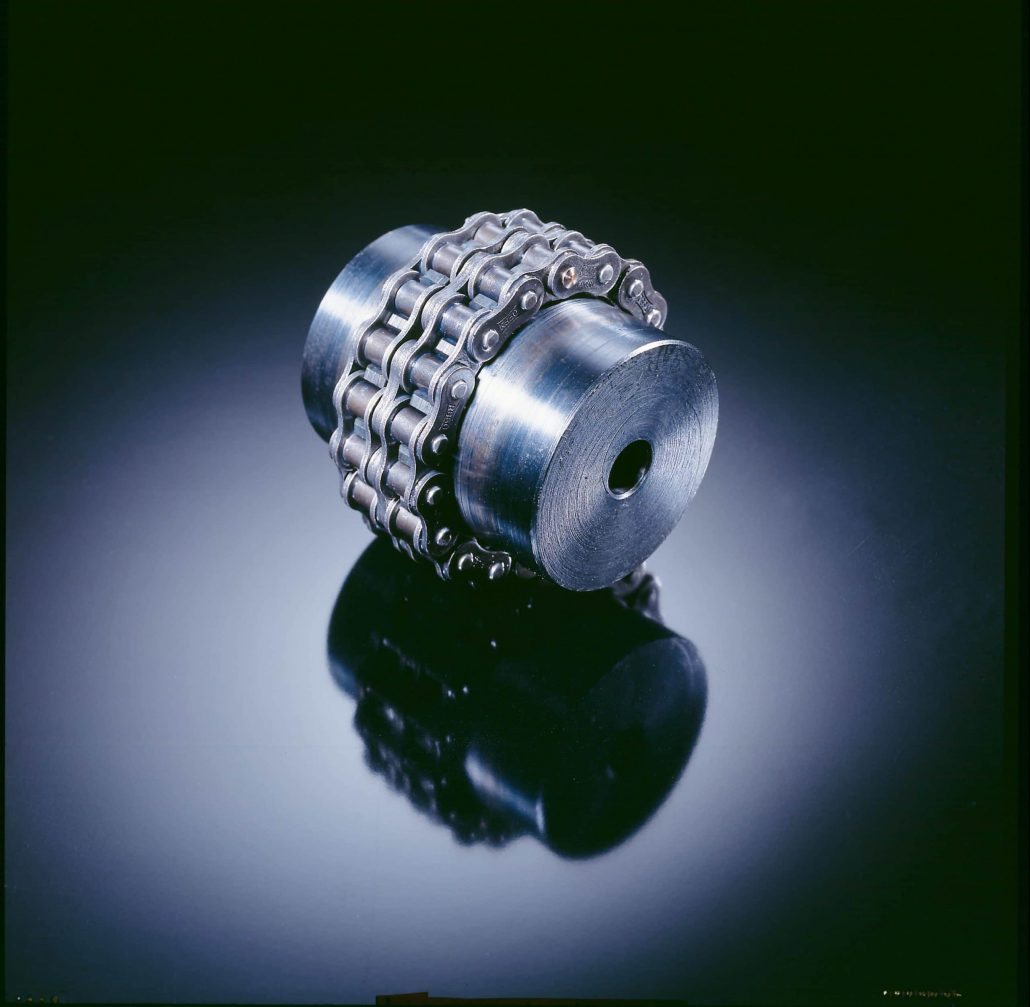

Chain couplings, a staple in mechanical power transmission, are known for their reliability and efficiency. However, like any mechanical component, they can encounter issues that need quick attention. We’ll discuss common problems associated with chain couplings and provide a troubleshooting guide to help address these issues effectively.

1. Misalignment

Problem: Misalignment between connected shafts can lead to chain coupling problems. Misalignment can be angular, parallel, or a combination of both, resulting in uneven wear and premature failure.

Solution: Properly align the shafts before coupling installation. Align both parallel and angular misalignment to minimize wear and ensure efficient power transmission.

2. Chain Elongation and Wear

Problem: Over time, chains in a chain coupling can elongate and wear due to friction and load, potentially leading to issues like backlash and reduced efficiency.

Solution: Regularly inspect the chain for signs of wear and elongation. Replace chains that have reached their wear limit. Ensure the chain is properly tensioned according to the manufacturer’s recommendations.

3. Lubrication Problems

Problem: Inadequate or improper lubrication can result in chain coupling issues, including chain and sprocket wear, increased friction, and heat generation.

Solution: Follow the manufacturer’s recommendations for lubrication type and frequency. Maintain a consistent and adequate lubrication schedule to ensure the smooth operation of the coupling.

4. Backlash

Problem: Backlash in a chain coupling can occur when there’s a gap between the chain and the sprocket teeth. This can lead to reduced precision and efficiency.

Solution: Check and adjust the chain tension to eliminate backlash. Properly tensioned chains ensure a snug fit between the chain and the sprocket teeth, reducing backlash.

5. Sprocket Misalignment

Problem: If the sprockets on both shafts are misaligned, it can lead to uneven loading and wear on the chain.

Solution: Ensure that the sprockets are aligned with each other and that they are concentric with the shafts. Proper alignment minimizes wear and prolongs the life of the chain.

6. Overloading

Problem: Subjecting a chain coupling to loads beyond its capacity can result in chain and sprocket damage and premature failure.

Solution: Choose the right-sized chain coupling for the application, ensuring it can handle the intended load. Regularly inspect the coupling for signs of overloading and replace components as needed.

7. Chain Jumping or Skipping

Problem: Chain jumping or skipping can occur when the chain doesn’t properly engage with the sprocket teeth. This can lead to intermittent or erratic operation.

Solution: Check for chain wear, sprocket wear, or inadequate chain tension. Address the issue by replacing worn components and properly tensioning the chain.

8. Corrosion and Contamination

Problem: Environmental factors can lead to chain and sprocket corrosion and contamination, resulting in premature wear and coupling problems.

Solution: Protect the chain coupling from harsh environments and corrosive substances. Use suitable protective measures, such as seals and covers, to prevent contamination and corrosion.

9. Routine Inspection and Maintenance

Problem: Neglecting routine inspection and maintenance can allow problems to go unnoticed, leading to more significant issues over time.

Solution: Implement a regular maintenance schedule that includes visual inspections, lubrication checks, and chain tension assessments. Promptly address any identified issues.

Chain couplings, when properly maintained and used, provide reliable and efficient power transmission in various applications. Recognizing and addressing common problems is essential for ensuring the longevity and performance of chain couplings. Regular inspections, maintenance, proper alignment, and lubrication practices can go a long way in preventing and resolving issues, keeping chain couplings running smoothly in diverse industrial settings.

CONTINUE READING

Related Posts

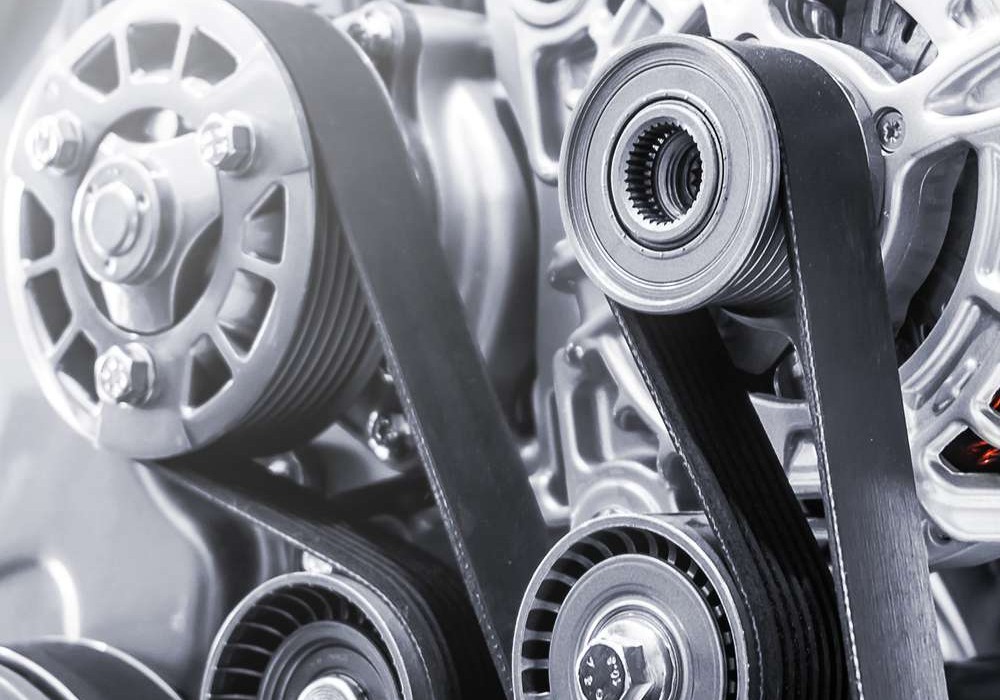

Serpentine and V-belt alternator pulleys are two types of pulleys used in automotive engines to transfer power from the engine […]

Engine pulleys and motor pulleys are both types of pulleys, but they serve different functions and are designed for different […]

Belts and pulleys are components used in power transmission systems to transmit power from one rotating shaft to another. Belts […]