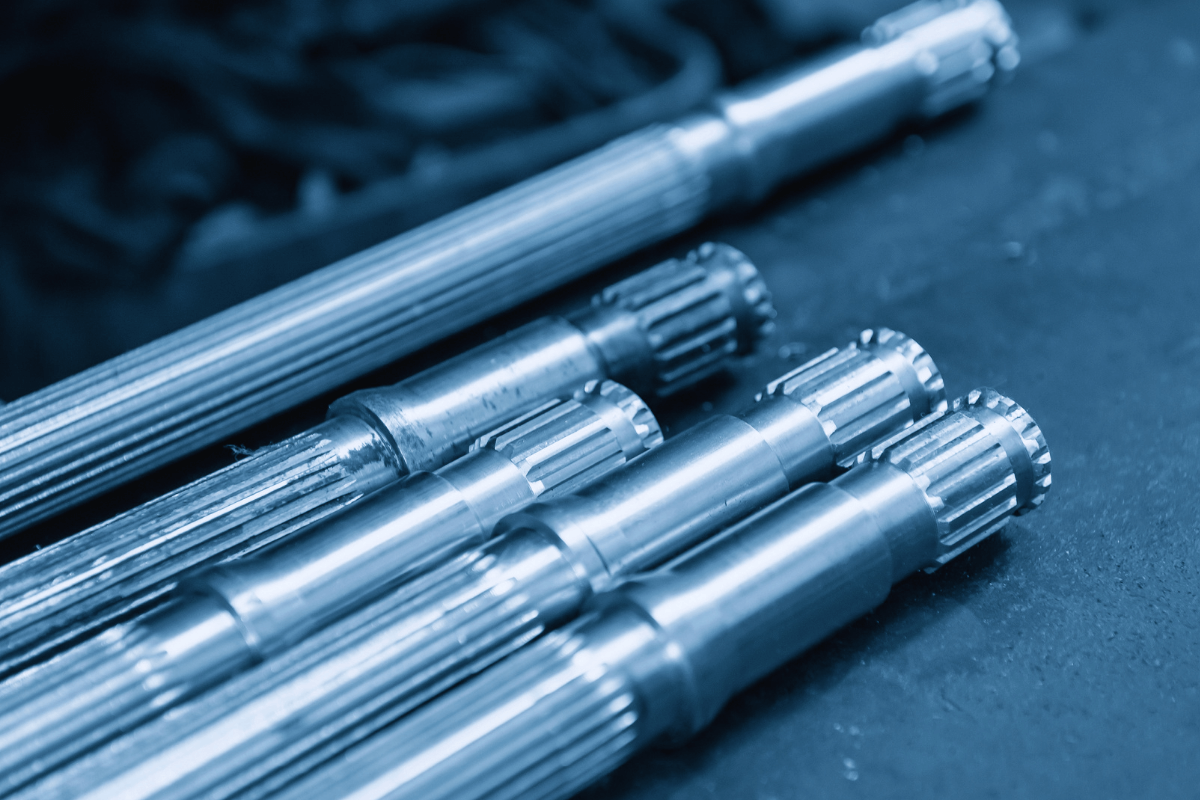

Spline gears are an essential component of many industrial and mechanical systems, playing a crucial role in power transmission and motion control. To ensure their longevity and reliability, it is essential to perform regular maintenance practices on these gears.

Understanding Spline Gear Design and Operation

Before performing any maintenance procedures, it is crucial to understand the design and operation of the spline gears. This knowledge will help in identifying potential weak points and areas that are prone to wear and tear. Understanding the materials utilized in gear construction, along with comprehending the types of loads and operating conditions they’re intended to manage, is crucial. Consequently, it facilitates effective maintenance planning.

Regular Inspections

Regular inspections are crucial for identifying any issues or potential problems with the spline gears. Regularly checking for cracks, wear, and other signs of damage can help detect problems early and prevent them from escalating into more significant issues. Inspections should be performed at regular intervals, taking into account the operating conditions and load factors experienced by the gears.

Cleaning and Lubrication

Cleaning and lubrication are essential for maintaining the smooth operation of spline gears. Regularly removing dirt, debris, and other contaminants from the gear teeth and bearing surfaces can help prevent premature wear and ensure proper lubrication. Appropriate lubrication not only decreases friction but also shields the gears from corrosion and other potential forms of damage.

Adjustment and Alignment

Regular adjustment and alignment of spline gears is crucial for maintaining their efficiency and reducing wear. If the gears are not properly aligned, uneven loading can result, leading to premature wear and potential failure. Regularly checking and adjusting the alignment of the gears ensures that they operate within their designed parameters, reducing stress and wear on critical components.

Monitoring Operating Conditions

Moreover, monitoring the operating conditions of spline gears is crucial for identifying potential issues or changes in performance. Keeping track of temperature, vibration, and other relevant parameters can offer valuable insights into gear health. Upon observing any unusual operating conditions or performance changes, prompt action should be taken to investigate and address the issue.

Preventive Maintenance Scheduling

Furthermore, preventive maintenance scheduling plays a pivotal role in proactively upholding the condition of spline gears. Establishing regular maintenance intervals, considering operating conditions, load factors, and gear age, is crucial. This approach encompasses cleaning, lubrication, inspection, adjustment, and other necessary procedures to ensure gear longevity and reliability.

Replacement Parts Management

Effective replacement parts management is crucial for maintaining the availability and performance of spline gears. Stocking replacement parts for timely repairs and replacements can help minimize downtime and maximize equipment availability. Additionally, knowledge of reliable suppliers and parts distributors can ensure access to high-quality replacement parts at competitive prices.

Spline gear maintenance practices are essential for prolonging lifespan and reliability. Understanding spline gear design and operation, regular inspections, cleaning and lubrication, adjustment and alignment, monitoring operating conditions, preventive maintenance scheduling, and replacement parts management are key factors in maintaining the performance and durability of these gears. Implementing these practices proactively can help reduce downtime, minimize equipment failures, and improve overall equipment availability.

More: Choosing the Right V-Pulley for Your Application: Key Factors to Consider

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]