A sprocket is a wheel with cog-type buckle teeth, which is used to mesh with a block with an accurate pitch on a link or cable. A solid or spoked gear that meshes with a (roller) chain to pass movement.

The sprocket is a wheel used for chain transmission, and there are teeth that mesh with the chain on the edge. Sprockets are different from gears, which will directly contact other gears, while the sprocket will contact the chain instead of other sprockets. The sprocket is also different from the pulley, which has a smooth edge, while the surface of the sprocket has teeth that match the chain.

What role does the tooth profile of the sprocket play?

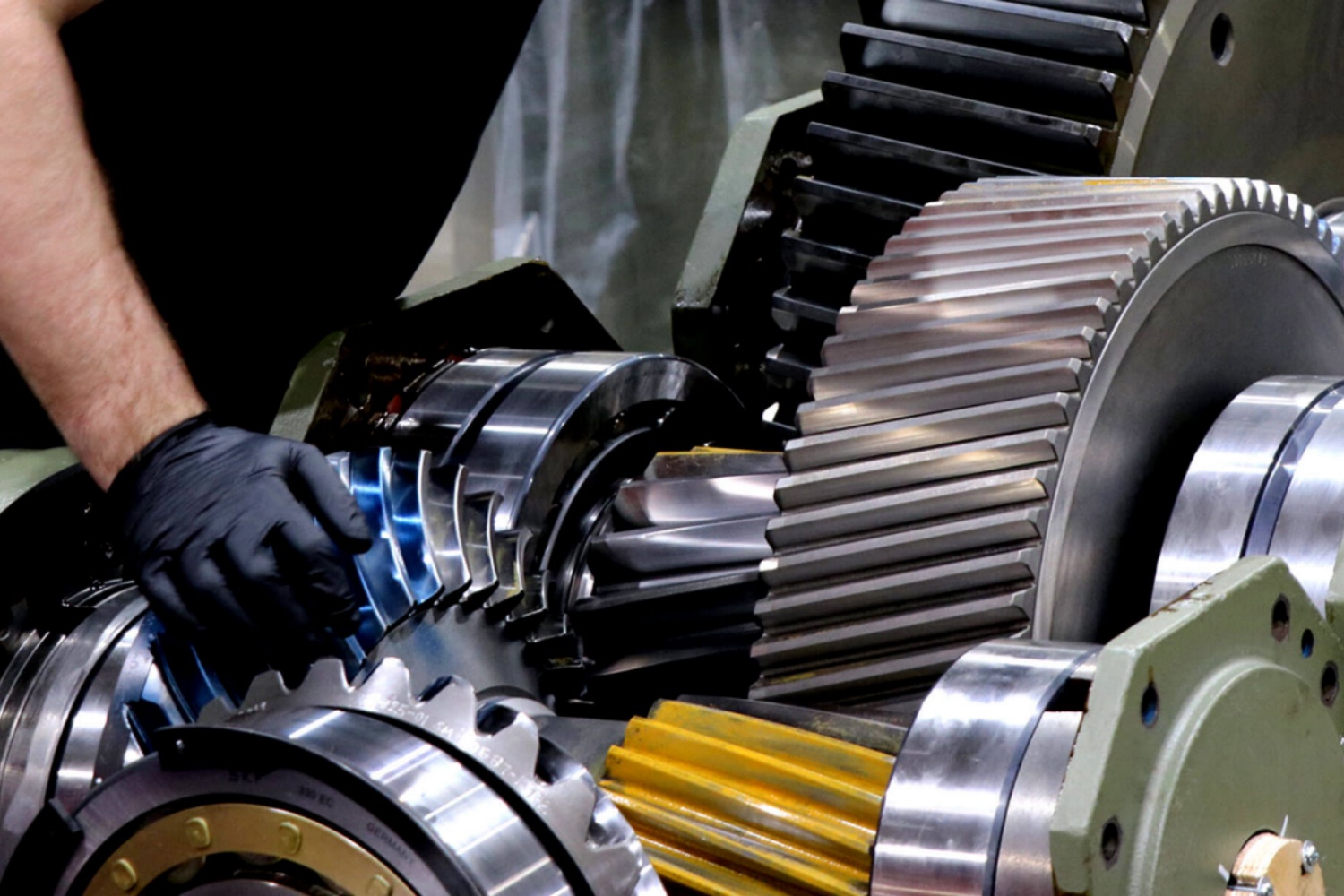

The sprocket itself is a bit similar to the shape of a gear, and it can achieve a very good effect when used in many situations that require medium- and high-speed rotation. So why is it necessary to design it into a gear row shape, and what effect can it play after being designed like this?

You can see that its shape is very similar to the shape of the gear during the usage, but this kind of toothed sprocket is very flexible when being used. It can ensure that the entire link can rotate steadily and smoothly while being used, and can reduce the stress generated by the link and gear in the process of combining as much as possible. What’s more, it can avoid well some problems caused by the wear of the sprocket. And this kind of toothed sprocket is also very convenient to process, it can be processed into a straight arc or a double arc and other tooth shapes of different shapes, which is very helpful for the use links.

Currently this method for transmission is a very efficient technology, which is also in continuous development and innovation. At the same time, it reduces the cost of maintenance and other aspects to a very large extent, so it has been applied well in various mechanical fields.

The above is a short introduction of the role played by the tooth shape of the sprocket. Actually, the tooth-shaped sprocket is also designed to achieve a better conveying effect during the use of the parts. However, the tooth-shaped sprocket needs to be regularly maintained and inspected while being used. It needs to be replaced in time if the tooth is found to be seriously damaged.

CONTINUE READING

Related Posts

In the intricate machinery that propels modern industries, the unassuming but critical component known as the industrial sprocket plays a […]

In the pulsating core of precision that powers industrial machinery, the intricate realm of industrial spline gears emerges as a […]

In complex industrial machinery, precision and reliability are crucial. Oris Gear Solutions serves as a beacon of innovation, seamlessly combining […]