Spur gears stand as the quintessential cog in the machinery of various industries, serving a multitude of applications with simplicity, efficiency, and reliability. Their straightforward construction, comprised of interlocking toothed wheels, facilitates the seamless transmission of power, rendering them indispensable across diverse sectors. In this comprehensive overview, we delve into the intricacies of spur gears, exploring their functionalities, advantages, applications, and challenges.

Understanding Spur Gears:

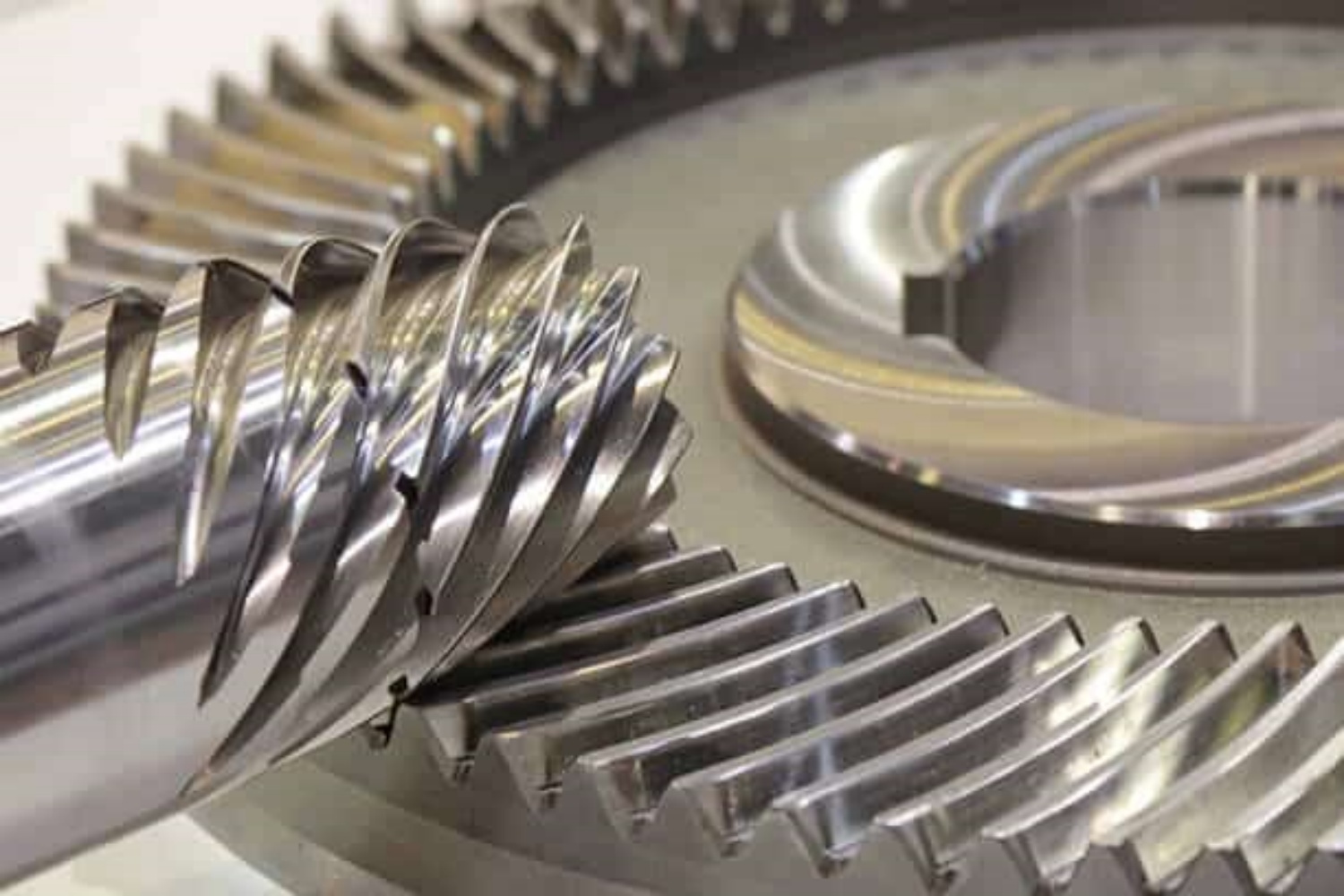

Spur gears, characterized by parallel shafts and straight teeth, operate by meshing perpendicularly to transmit power from one gear to another. Their design simplicity and ease of manufacture underscore their widespread usage in countless applications. From optimizing rotational speed to bidirectional power transmission, spur gears offer versatility and efficacy unparalleled by their counterparts.

Advantages and Disadvantages:

The advantages of spur gears are manifold. Their simplicity in design and manufacturing renders them cost-effective solutions for various industries. With transmission efficiencies reaching up to 98%, they stand as paragons of power transfer efficiency. Moreover, their durability withstands horizontal and dynamic loads, while their versatility allows deployment across a spectrum of applications.

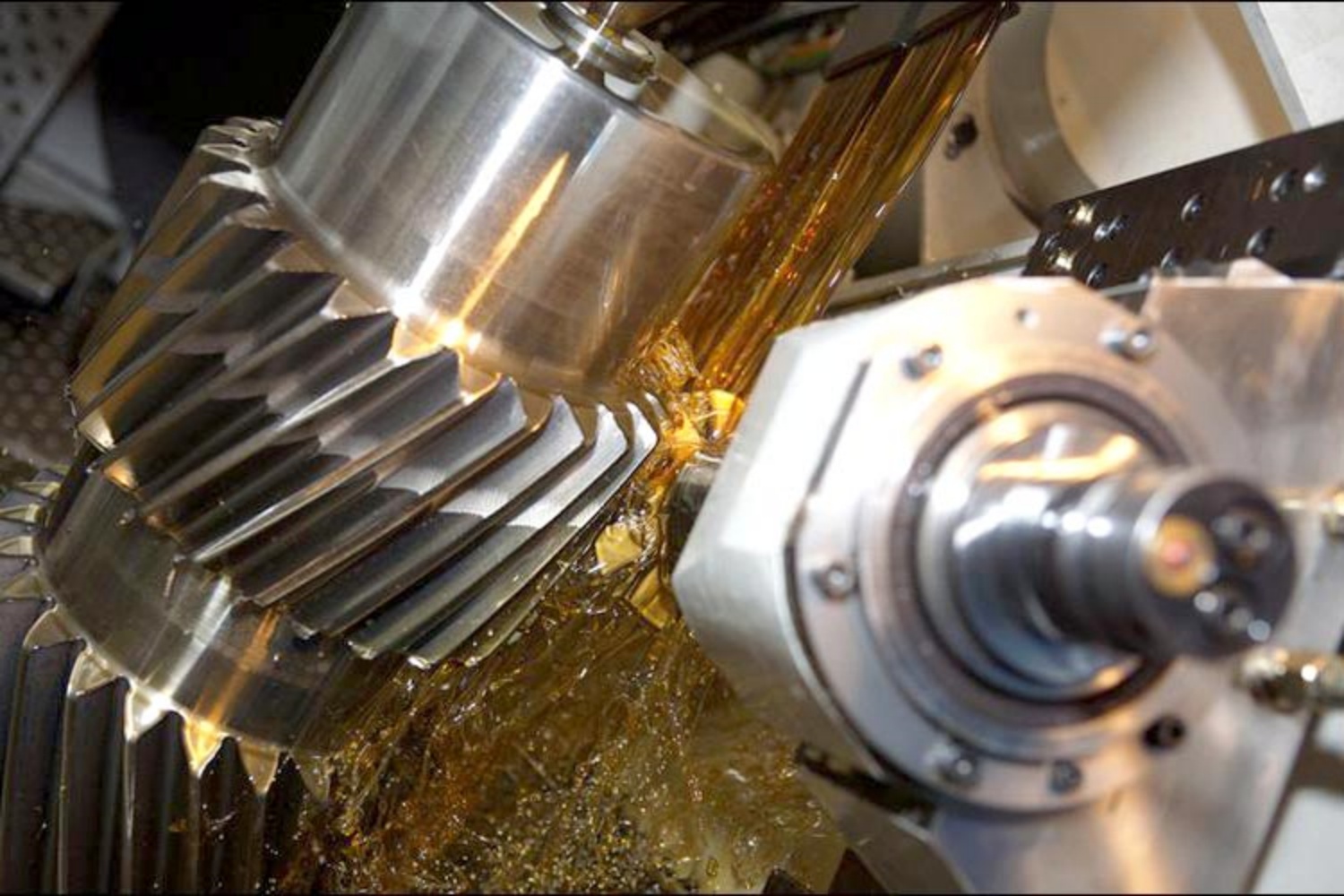

However, spur gears are not without their limitations. Operating at high speeds, they can emit considerable noise, posing challenges in noise-sensitive environments. Backlash, the inherent play between gear teeth, can induce vibration and noise, compromising gearing accuracy. Additionally, the centrifugal force generated at elevated speeds limits their practicality, necessitating careful consideration in high-speed applications.

Spur Gear Applications Across Industries:

The ubiquity of spur gears spans myriad industries, each benefiting from their unique attributes:

- Agriculture: Spur gears find application in farm equipment such as tractors, combines, and irrigation systems, optimizing agricultural processes.

- Automotive: From transmissions to power steering systems, spur gears form the backbone of automotive machinery, ensuring efficient power transfer and maneuverability.

- Construction: Construction machinery relies on spur gears for functionalities ranging from lifting to earthmoving operations, enhancing productivity and precision.

- Electro-Electronics: In generators, motors, and robotics, spur gears facilitate seamless power transmission, driving innovation in electro-electronic devices.

- Food and Beverage: Spur gears power food processing equipment, from mixers to conveyor belts, streamlining production in the food and beverage industry.

- Mining: Drills, conveyors, and crushers in mining machinery leverage the robustness of spur gears to withstand rigorous operational demands.

- Oil and Gas: Spur gears play a vital role in oil and gas drilling and production equipment, ensuring reliable performance in challenging environments.

- Power Generation: Turbines and generators rely on spur gears for efficient power generation, contributing to the global energy infrastructure.

- Textiles: Spinning and sewing machines in textile manufacturing benefit from the precision and durability of spur gears, enhancing production efficiency.

Selecting Spur Gears:

When considering spur gears for an application, factors such as efficiency, durability, and versatility are paramount. Spur gears excel in delivering power efficiently while withstanding horizontal loads and movement, making them ideal candidates for a myriad of industrial settings.

Overcoming Challenges:

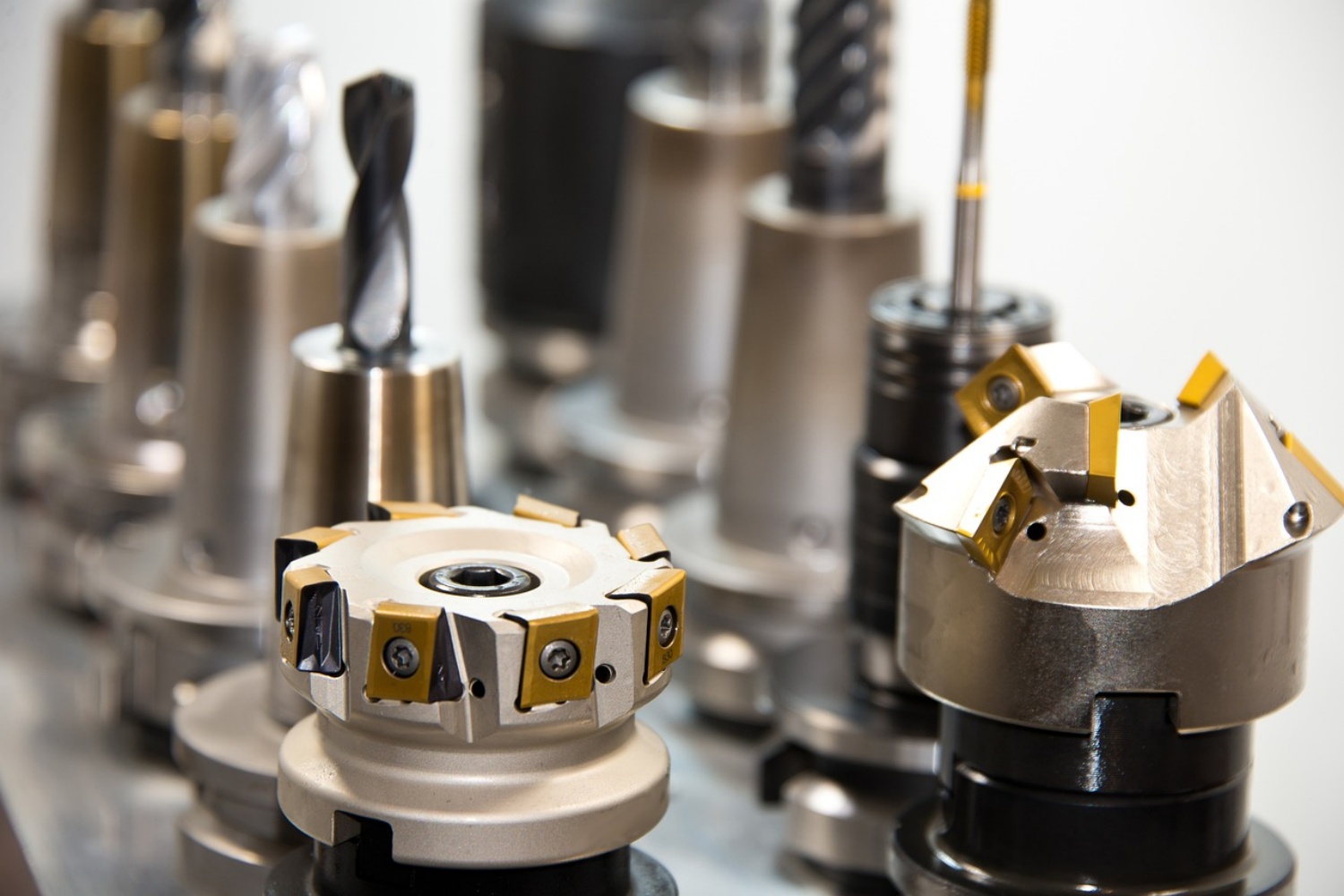

The challenges posed by spur gears, including noise and backlash, necessitate proactive mitigation strategies. Precision machining techniques and meticulous lubrication can mitigate noise levels, while gear designs with reduced pitch and materials with low thermal expansion coefficients can minimize backlash, ensuring smooth and accurate operation.

Spur gears epitomize efficiency, reliability, and versatility, serving as linchpins in the machinery of modern industries. While their advantages are manifold, challenges such as noise and backlash underscore the importance of tailored solutions and meticulous maintenance. Nevertheless, with strategic implementation and innovation, spur gears continue to drive progress across diverse sectors, cementing their status as indispensable components in the industrial landscape.

CONTINUE READING

Related Posts

V-pulley production is a crucial aspect of the power transmission industry, where reliability and durability are paramount. A well-made V-pulley […]

In today’s world, sustainability has become a key factor in manufacturing practices, with companies increasingly realizing the need to operate […]

Spline gears are an essential component of many industrial and mechanical systems, playing a crucial role in power transmission and […]