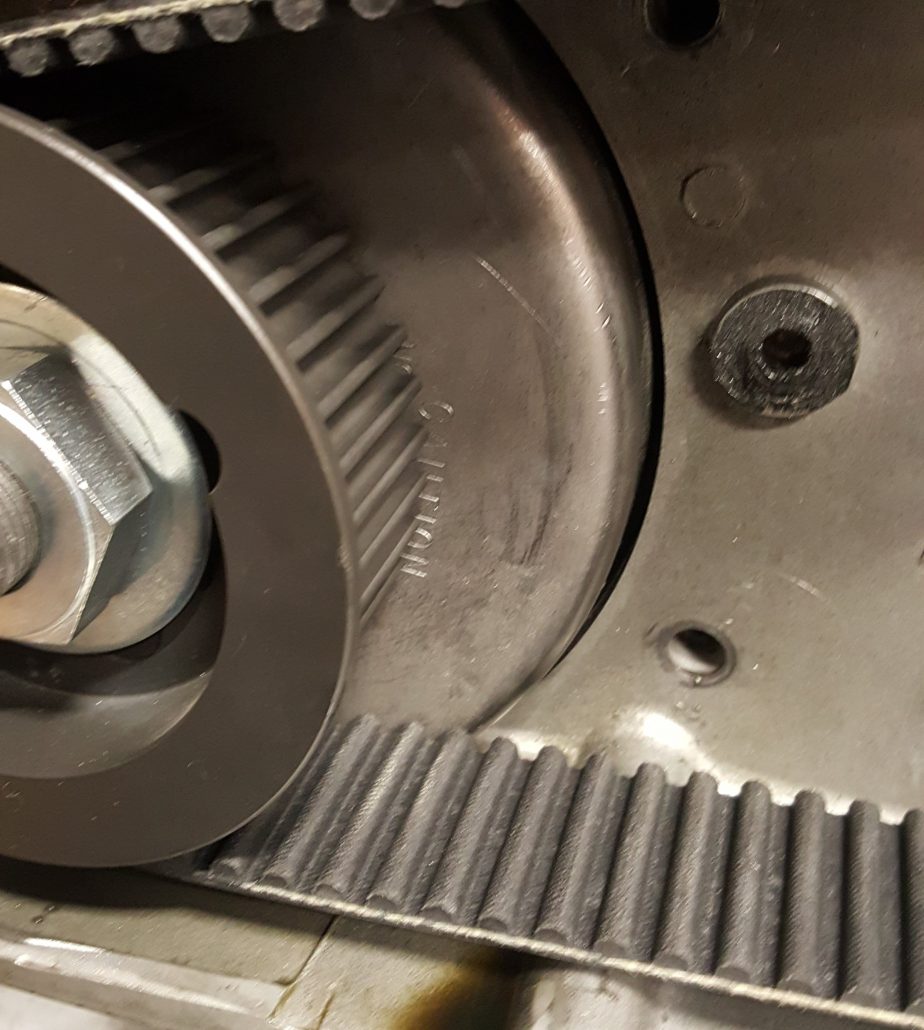

In the intricate world of industrial manufacturing, specialized machinery is essential for achieving precision and efficiency. One key component that often goes unnoticed but plays a crucial role is the sprocket. As a transmission device, sprockets transfer power from one component to another, ensuring smooth operation. However, the traditional one-size-fits-all approach often limits the performance and efficiency of machinery. This is where custom sprockets come into play, offering tailored precision and adaptability to meet the specific needs of specialized machinery.

Custom Sprockets: The Evolution of Precision

Custom sprockets are designed to address the unique challenges and requirements of specialized machinery. They are precision-engineered to fit specific applications, ensuring optimal performance and efficiency. By working closely with manufacturers, engineers can tailor the size, shape, tooth profile, material, and other features of sprockets to match the specific needs of the machinery. This level of customization enables better power transmission, reduced vibrations, and longer equipment lifespan.

Benefits of Custom Sprockets

The advantages of using custom sprockets in specialized machinery are numerous. Here are some of the key benefits:

- Increased Precision: Tailored sprockets allow for greater precision in power transmission, leading to more accurate and consistent operations. They reduce vibrations and other forms of irregularities, ensuring smoother operations and improved productivity.

- Enhanced Performance: By optimizing the design and material of sprockets for specific applications, machinery can achieve higher levels of performance. Custom sprockets enable better torque transmission, faster acceleration, and improved overall system efficiency.

- Extended Equipment Lifespan: Custom sprockets are designed to withstand the rigors of industrial environments, providing longer equipment lifespan. They are stronger, more durable, and better suited to handle the stresses and strains associated with specialized machinery operations.

- Reduced Maintenance Costs: With custom sprockets, there’s less need for frequent replacements and repairs. The precision-engineered design reduces wear and tear on machinery components, ultimately cutting down on maintenance costs and improving uptime.

- Improved Safety: In addition to enhancing performance and efficiency, custom sprockets can also improve safety in industrial settings. Their precise design reduces the potential for equipment failure or operator injuries, providing added peace of mind for operators and managers alike.

The Future of Custom Sprockets

As technology continues to advance, the role of custom sprockets in specialized machinery is becoming increasingly important. As demand for more efficient, precise, and cost-effective manufacturing processes grows, the need for precision-engineered sprockets will continue to rise. As material science and manufacturing technologies evolve, engineers will have even more opportunities to create innovative sprocket designs that further enhance the performance of specialized machinery.

Custom sprockets are a critical component in specialized machinery, playing a pivotal role in ensuring precision, performance, and efficiency. By investing in tailored sprockets, manufacturers can gain a competitive edge in today’s demanding manufacturing environment, delivering superior products while reducing costs and enhancing safety.

More: Adapting to Agriculture: Customized V-Belt Pulleys Meeting Diverse Agricultural Needs

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]