In the intricate machinery that propels modern industries, the unassuming but critical component known as the industrial sprocket plays a role akin to the backbone in the human body. While often overlooked, its significance in ensuring the smooth and precise functioning of various mechanisms cannot be overstated.

Understanding the Basics

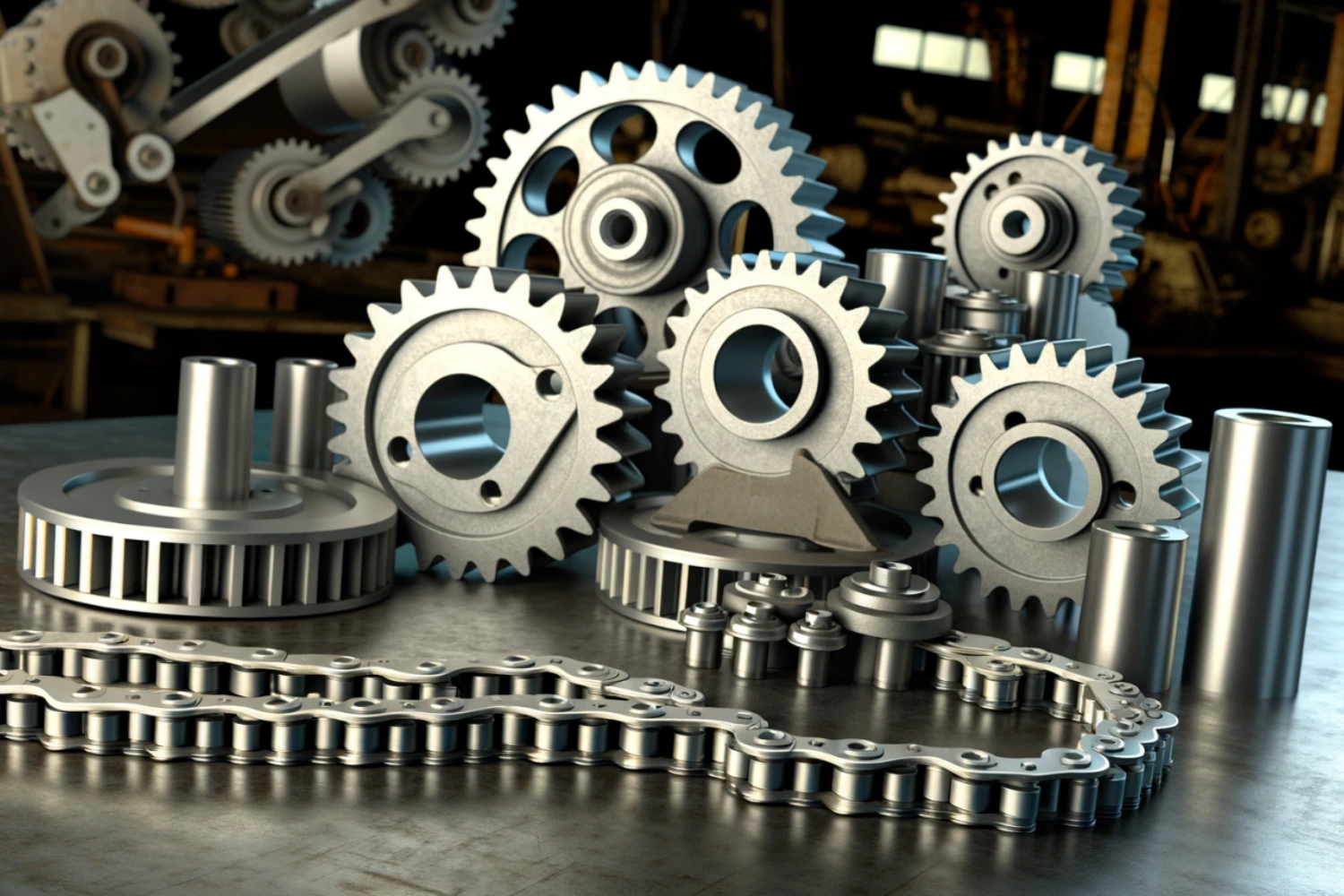

Industrial sprockets are toothed wheels that mesh with a chain or track, translating rotary motion between two shafts. These components come in various sizes and designs, adapted to diverse applications across industries. While seemingly simple, their intricate design is crucial for maintaining optimal performance and longevity of machinery.

Power Transmission Prowess

One of the primary functions of industrial sprockets lies in power transmission. Linked with chains or belts, they efficiently transfer power from one rotating shaft to another. This capability is fundamental in numerous applications, from conveyor systems in manufacturing plants to the propulsion of heavy machinery in construction.

Precision in Motion

The teeth of an industrial sprocket are meticulously designed to engage with the links of a chain or the cogs of a belt. This precision ensures a synchronized and smooth transfer of motion, minimizing friction and wear. In manufacturing processes where precision is paramount, industrial sprockets play a critical role in maintaining the accuracy of movements.

Adaptability to Diverse Industries

Industries ranging from automotive and manufacturing to agriculture and mining leverage the adaptability of industrial sprockets. Different configurations, such as single, double, or triple sprockets, allow for customization based on the specific requirements of each application. This adaptability enhances the versatility of these components.

Durability Under Stress

The industrial environment is often harsh, with machinery subjected to heavy loads, high speeds, and exposure to contaminants. Industrial sprockets are engineered to withstand such conditions. Materials like hardened steel or alloys are common choices, providing the necessary durability to endure the rigors of industrial operations.

Maintenance and Longevity

While robust, industrial sprockets are not invincible. Regular maintenance is essential to prevent wear and tear. Lubrication and periodic inspections are routine practices to ensure the longevity of both the sprockets and the entire machinery. Timely replacements of worn-out sprockets contribute to the overall efficiency and safety of industrial processes.

Innovation in Design

As technology advances, so does the design of industrial sprockets. Innovations in materials, coatings, and manufacturing processes continually push the boundaries of what these components can achieve. Reduced friction, increased efficiency, and enhanced durability are among the benefits seen in the latest generations of industrial sprockets.

Environmental Impact

In an era where sustainability is a global imperative, industrial sprocket manufacturers are increasingly focusing on environmentally friendly practices. The use of eco-friendly materials and processes not only aligns with corporate responsibility but also addresses the growing demand for greener industrial solutions.

In the vast machinery landscape, industrial sprockets stand as silent heroes, facilitating the seamless operation of diverse processes. From the rhythmic clatter of conveyor belts in manufacturing plants to the steady hum of agricultural machinery, these unassuming components play a crucial role in powering the backbone of industry. Understanding their significance is key to appreciating the intricacies that keep our industrial world in motion.

CONTINUE READING

Related Posts

In the world of industrial manufacturing, the efficiency and reliability of transmission systems are critical to the success of any […]

In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt […]

Splines play a critical role in mechanical power transmission systems, enabling rotational motion and torque transfer between mating components. These […]