Toothed alternator pulleys are an essential component in modern automotive engines, providing a reliable and efficient method of power transmission from the engine to the alternator. They are specifically designed to improve the efficiency and performance of the alternator, ensuring that it produces a consistent output voltage and runs smoothly even at high engine speeds. In this article, we will discuss the features, benefits, and applications of toothed alternator pulleys.

Features of Toothed Alternator Pulleys:

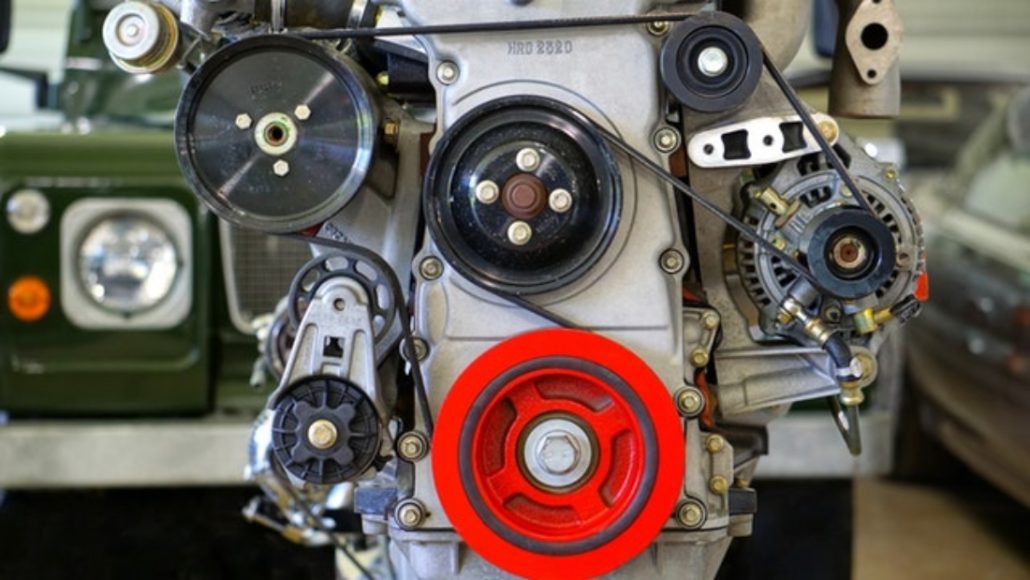

Toothed alternator pulleys differ from traditional smooth pulleys in that they have a series of teeth or grooves machined into the surface of the pulley. These teeth mesh with a corresponding toothed belt, providing a positive engagement and eliminating slippage that can occur with traditional v-belts or flat belts.

Toothed alternator pulleys are typically made of high-strength materials, such as steel or aluminum, to withstand the high speeds and loads experienced in automotive applications. They may be machined or cast to ensure precise tooth geometry and proper fit with the toothed belt.

Benefits of Toothed Alternator Pulleys:

- Improved Efficiency: Toothed alternator pulleys provide a more efficient power transmission than traditional v-belts or flat belts. This is because they have a positive engagement with the toothed belt, eliminating slippage and reducing energy losses due to friction.

- Smooth Operation: Toothed alternator pulleys provide a smooth and consistent transfer of power, without the jarring or jerking motions that can be experienced with traditional belts. This helps to reduce wear and tear on the alternator and extends its service life.

- Reduced Noise: Toothed alternator pulleys produce less noise than traditional v-belts or flat belts, due to the positive engagement between the teeth on the pulley and the teeth on the belt. This can help to improve passenger comfort and reduce driver distraction.

- Increased Alternator Performance: Toothed alternator pulleys can improve the performance of the alternator by ensuring a consistent output voltage and reducing the load on the bearings. This can lead to improved battery charging and reduced alternator wear.

Applications of Toothed Alternator Pulleys:

Toothed alternator pulleys are widely used in modern automotive engines, where they are typically installed in conjunction with a toothed serpentine belt that drives multiple accessories, such as the power steering pump, air conditioning compressor, and water pump. They are also used in heavy-duty equipment, such as construction machinery and agricultural equipment, where reliable power transmission is critical for efficient operation.

Precautions When Using Toothed Alternator Pulleys:

- Proper Installation: Toothed alternator pulleys must be installed properly to ensure precise tooth engagement with the belt. Failure to install the pulley correctly can result in belt slip, reduced alternator performance, and premature wear.

- Compatibility: Toothed alternator pulleys must be compatible with the toothed belt being used. Using a pulley that is not designed for the belt can result in premature wear, belt slip, and reduced alternator performance.

- Maintenance: Toothed alternator pulleys require periodic inspection and maintenance to ensure proper operation. This may include lubrication of the bearings, replacement of worn or damaged components, and adjustment of the belt tension.

Conclusion:

Toothed alternator pulleys are a critical component in modern automotive engines, providing a reliable and efficient method of power transmission from the engine to the alternator. They offer improved efficiency, smooth operation, reduced noise, and increased alternator performance compared to traditional v-belts or flat belts. When used properly and maintained correctly, toothed alternator pulleys can help to ensure the reliable operation of the alternator and extend its service life. If you are looking for a reliable power

CONTINUE READING

Related Posts

In the ever-evolving world of industrial machinery, the quest for components that enhance performance, durability, and efficiency is relentless. Among […]

In the vast field of industrial machinery, the importance of specific components can sometimes be overshadowed by the complexities of […]

Agricultural machinery plays a vital role in modern farming, contributing to increased efficiency, productivity, and profitability. At the heart of […]