When it comes to V belt pulleys, there are different types of pulleys available on the market. Two common types are industrial V belt pulley and ordinary V belt pulley. Although they look similar, there are some significant differences between the two. In this article, we will discuss these differences and help you understand which type of V belt pulley is suitable for your application.

Industrial V Belt Pulley

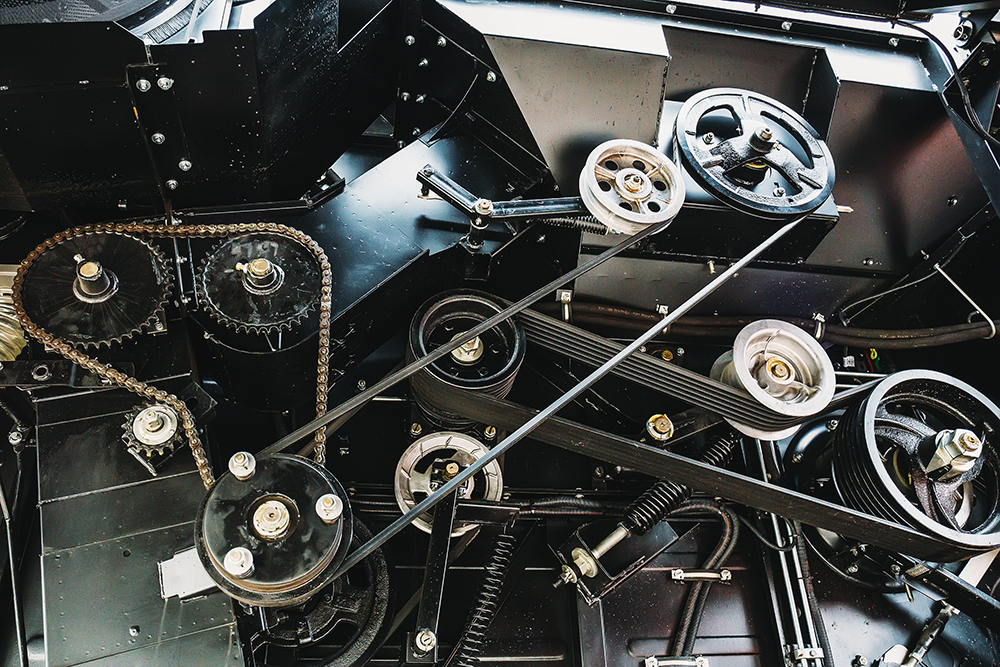

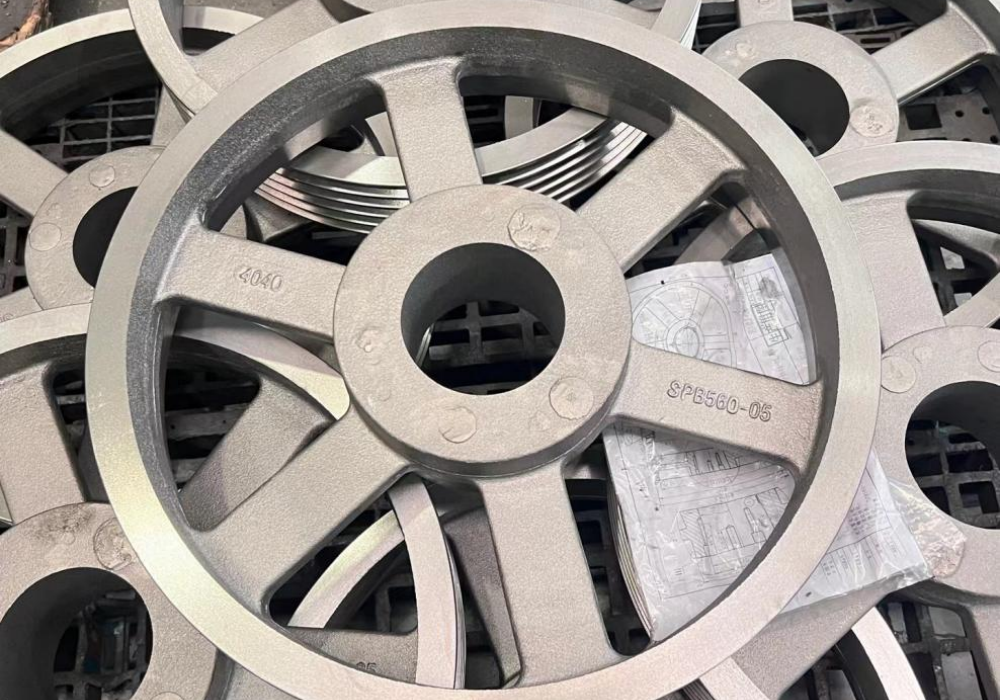

Industrial V belt pulleys are designed for heavy-duty applications in industries such as manufacturing, mining, and construction. These pulleys are made of high-quality materials such as cast iron or steel, which gives them greater strength and durability than ordinary V belt pulleys. Industrial V belt pulleys are also designed to handle greater loads and higher speeds than ordinary V belt pulleys.

One of the main differences between industrial V belt pulleys and ordinary V belt pulleys is their construction. Industrial V belt pulleys have a heavier and more robust construction, which allows them to handle the stresses of heavy-duty applications. These pulleys are also designed with wider belt grooves to accommodate larger V belts.

Another significant difference is the accuracy of industrial V belt pulleys. These pulleys are made to higher tolerances than ordinary V belt pulleys, which means they are less likely to wear out or become misaligned. The higher accuracy of industrial V belt pulleys also ensures that the belt runs smoothly and with less vibration, which reduces wear and tear on both the belt and pulley.

Ordinary V Belt Pulley

Ordinary V belt pulleys, also known as standard V belt pulleys, are designed for use in light to medium-duty applications. These pulleys are typically made of lower-grade materials such as cast iron or aluminum, which makes them less expensive than industrial V belt pulleys.

The construction of ordinary V belt pulleys is also less robust than that of industrial V belt pulleys. They have narrower belt grooves and are not designed to handle the same loads and speeds as industrial V belt pulleys. However, they are suitable for applications where lighter loads and lower speeds are expected.

Another difference between ordinary V belt pulleys and industrial V belt pulleys is their availability. Ordinary V belt pulleys are readily available from a variety of sources, including online retailers, hardware stores, and auto parts stores. Industrial V belt pulleys, on the other hand, may require a specialized supplier or manufacturer to obtain.

Which Type of V Belt Pulley is Right for You?

Choosing the right type of V belt pulley depends on several factors, including the application, load, and speed requirements. Industrial V belt pulleys are suitable for heavy-duty applications where high loads and speeds are expected, such as in manufacturing, mining, and construction. Ordinary V belt pulleys are suitable for lighter duty applications such as in household appliances, power tools, and automobiles.

It is essential to select the correct type of V belt pulley to ensure proper operation and longevity of both the pulley and the belt. A mismatched V belt pulley can cause belt slippage, premature wear, and even belt failure. Therefore, it is critical to consult with a knowledgeable supplier or manufacturer to select the right V belt pulley for your application.

Conclusion

In conclusion, industrial V belt pulleys and ordinary V belt pulleys have several differences in terms of their construction, accuracy, load capacity, and availability. Industrial V belt pulleys are suitable for heavy-duty applications, while ordinary V belt pulleys are suitable for lighter duty applications. It is essential to select the correct type of V belt pulley for your application to ensure proper operation and longevity of both the pulley and the belt.

CONTINUE READING

Related Posts

V belt pulleys, also known as V grooved pulleys, are crucial transmission components in mechanical operations. Manufactured by Shanghai Oris, […]

V belt pulleys, also known as V grooved pulleys, are integral components in mechanical operations. These pulleys, manufactured by Shanghai […]

Throughout history, machined steel V belt pulleys have evolved in lockstep with technology, cementing their indispensable role in the industrial […]