When it comes to V belt pulleys, there are different types of pulleys available on the market. Two common types are industrial V belt pulley and ordinary V belt pulley. Although they look similar, there are some significant differences between the two. In this article, we will discuss these differences and help you understand which type of V belt pulley is suitable for your application.

Industrial V Belt Pulley

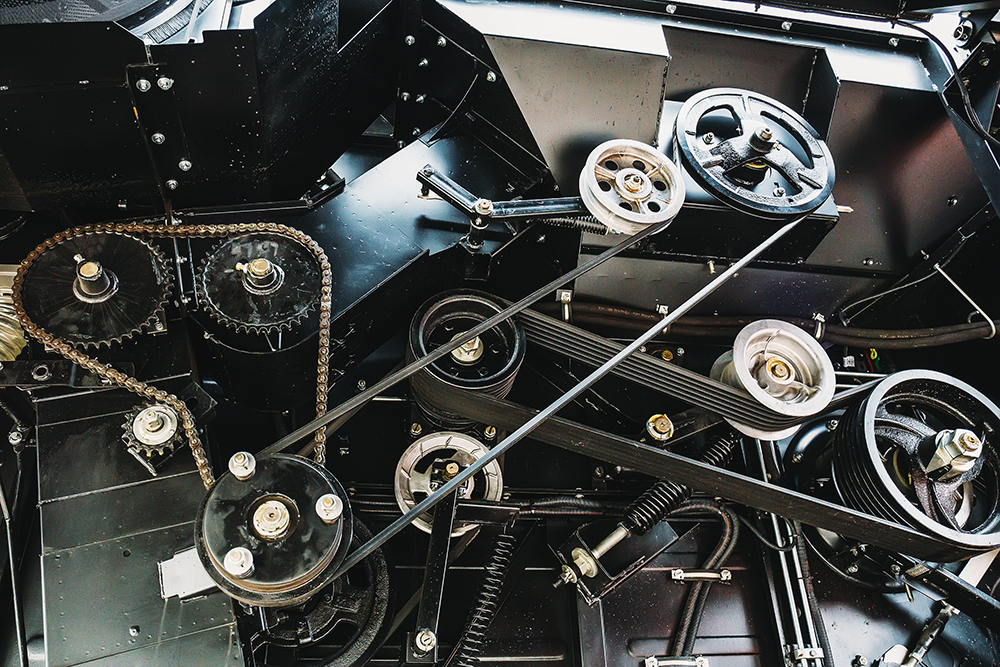

Industrial V belt pulleys are designed for heavy-duty applications in industries such as manufacturing, mining, and construction. These pulleys are made of high-quality materials such as cast iron or steel, which gives them greater strength and durability than ordinary V belt pulleys. Industrial V belt pulleys are also designed to handle greater loads and higher speeds than ordinary V belt pulleys.

One of the main differences between industrial V belt pulleys and ordinary V belt pulleys is their construction. Industrial V belt pulleys have a heavier and more robust construction, which allows them to handle the stresses of heavy-duty applications. These pulleys are also designed with wider belt grooves to accommodate larger V belts.

Another significant difference is the accuracy of industrial V belt pulleys. These pulleys are made to higher tolerances than ordinary V belt pulleys, which means they are less likely to wear out or become misaligned. The higher accuracy of industrial V belt pulleys also ensures that the belt runs smoothly and with less vibration, which reduces wear and tear on both the belt and pulley.

Ordinary V Belt Pulley

Ordinary V belt pulleys, also known as standard V belt pulleys, are designed for use in light to medium-duty applications. These pulleys are typically made of lower-grade materials such as cast iron or aluminum, which makes them less expensive than industrial V belt pulleys.

The construction of ordinary V belt pulleys is also less robust than that of industrial V belt pulleys. They have narrower belt grooves and are not designed to handle the same loads and speeds as industrial V belt pulleys. However, they are suitable for applications where lighter loads and lower speeds are expected.

Another difference between ordinary V belt pulleys and industrial V belt pulleys is their availability. Ordinary V belt pulleys are readily available from a variety of sources, including online retailers, hardware stores, and auto parts stores. Industrial V belt pulleys, on the other hand, may require a specialized supplier or manufacturer to obtain.

Which Type of V Belt Pulley is Right for You?

Choosing the right type of V belt pulley depends on several factors, including the application, load, and speed requirements. Industrial V belt pulleys are suitable for heavy-duty applications where high loads and speeds are expected, such as in manufacturing, mining, and construction. Ordinary V belt pulleys are suitable for lighter duty applications such as in household appliances, power tools, and automobiles.

It is essential to select the correct type of V belt pulley to ensure proper operation and longevity of both the pulley and the belt. A mismatched V belt pulley can cause belt slippage, premature wear, and even belt failure. Therefore, it is critical to consult with a knowledgeable supplier or manufacturer to select the right V belt pulley for your application.

Conclusion

In conclusion, industrial V belt pulleys and ordinary V belt pulleys have several differences in terms of their construction, accuracy, load capacity, and availability. Industrial V belt pulleys are suitable for heavy-duty applications, while ordinary V belt pulleys are suitable for lighter duty applications. It is essential to select the correct type of V belt pulley for your application to ensure proper operation and longevity of both the pulley and the belt.

CONTINUE READING

Related Posts

In the intricate machinery that powers industries worldwide, sprockets play a crucial role, serving as the driving force behind rotational […]

Industrial sprockets play a pivotal role in enhancing productivity and performance across a spectrum of industrial applications. From conveying systems […]

Spline gears are essential components in mechanical engineering, widely used for their ability to transmit torque and provide precise alignment […]