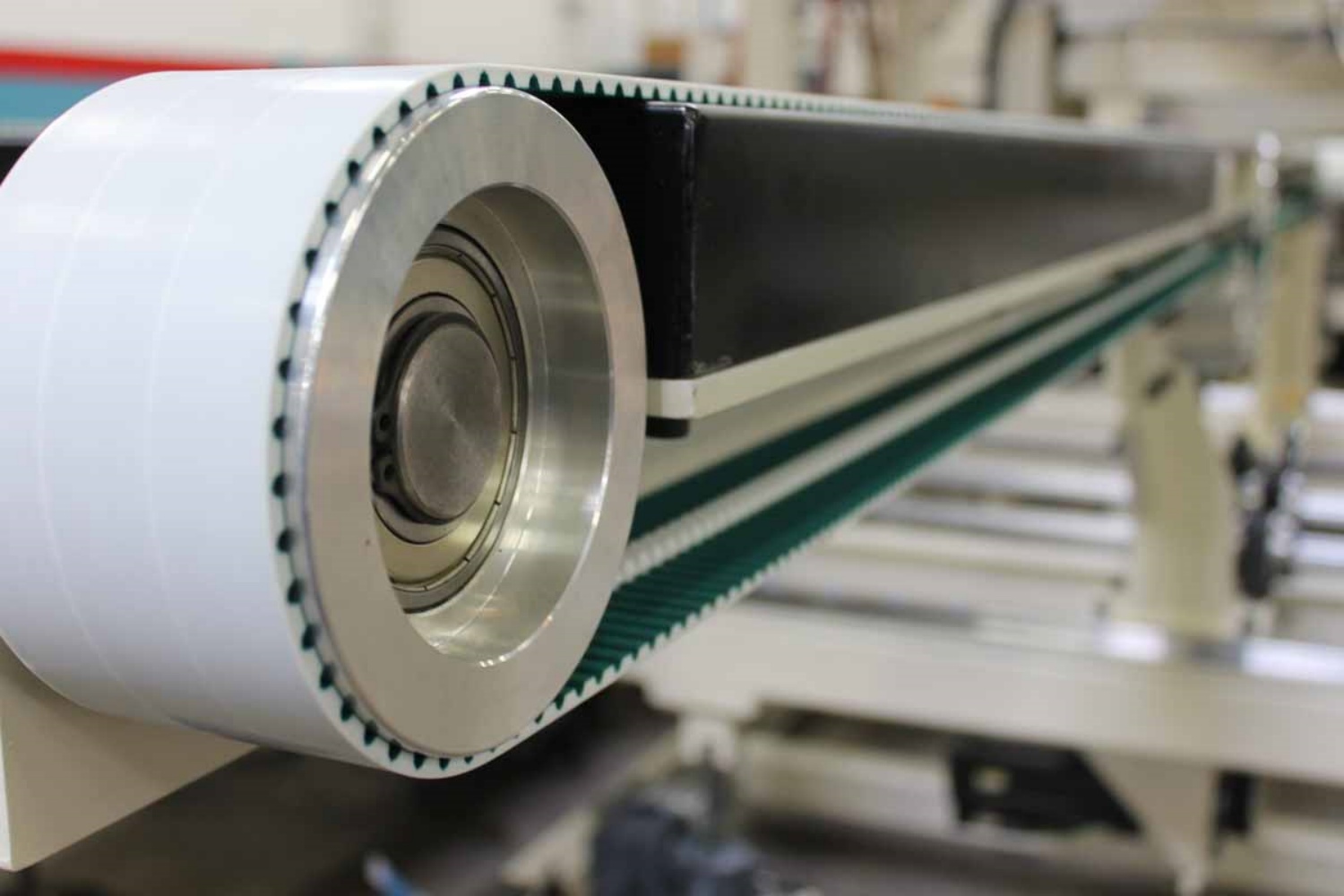

Pulleys, often underestimated, are critical in many applications, from the precise positioning required in high-tech machinery to the brute force needed in heavy industrial equipment. A well-chosen pulley isn’t just a part—it’s a solution to a mechanical challenge, ensuring that everything runs like clockwork. Whether it’s mitigating the risk of a timing belt slip in an automotive application or ensuring the seamless movement of a conveyor belt, the right pulley can dramatically impact the performance and longevity of a system.

Understanding Sprockets

Sprockets are a specific type of pulley characterized by their distinct tooth-like projections, which mesh perfectly with the links of a chain or gearbelt. These teeth (on a roller chain sprocket) or grooves (on a gearbelt pulley) are meticulously manufactured to ensure a precise fit, eliminating any slip between the sprocket and the belt or chain. The material the sprocket is made from, usually metals like steel or aluminum, is chosen based on the application’s specific needs and balancing factors like strength, weight, wear resistance, and cost.

Applications of Sprockets

Applications commonly use sprockets and gearbelt pulleys where high torque at low RPM is required. Examples include:

- Industrial Dough Mixers: Where consistent, high-torque mixing is necessary.

- Aggregate Elevators and Conveyors: Used in mining and material handling.

- Agricultural Equipment: Essential in machinery like combines and tractors.

They are also crucial in settings where timing is essential, such as automobile engines. Here, the timing pulleys and belts synchronize the movement of the engine’s valves and pistons, ensuring efficient operation. Additionally, sprockets allow for precision motion control and are integral to various machinery used in manufacturing and processing, including robotics and automated assembly lines.

Benefits of Sprockets

The primary advantage of sprockets is their ability to transmit large amounts of torque at low RPMs and to maintain precise alignment and timing, reducing the risk of slippage and misalignment. Sprockets are also highly customizable, designed with specific numbers of teeth and sizes to suit different applications. Their robust construction makes them highly durable and well-suited to high-stress environments.

Exploring Sheaves

Sheaves, another crucial type of pulley, are designed to accommodate V-belts and are characterized by their V-grooved circumference. These grooves are customized to match the cross-section of a V-belt, allowing friction-based transfer of power, with the V-belt wedged securely in the sheave’s grooves. Like sprockets, the material choice for sheaves is usually metal but can also include composites and plastics, depending on the application’s requirements.

Types and Applications of Sheaves

There are many types of sheaves, but one common type is the companion sheave, which plays a crucial role in variable speed drives. In these systems, the drive (dR) pulley can vary its diameter through various mechanical means. Its ability to vary its diameter, combined with an adjustable center distance between the drive and driven (dN) shafts, allows for changes in the output speed at the driven pulley. In this context, the companion sheave, which is the driven pulley, remains non-adjustable. It works with the adjustable drive pulley to facilitate the desired speed variation.

V-belt sheaves are ubiquitous, appearing in virtually every shape and size from the common automotive fan belt drive to massive rock-crusher applications found in mines and quarries. They are used in:

- Office Building Air-Handling Systems: Ensuring efficient air circulation.

- Air Compressors, Drill Presses, and Table Saws: Providing reliable power transfer in smaller applications.

- Powersports industries use variable pitch sheaves.

Benefits of Sheaves

Sheaves are beneficial because they can transmit power efficiently through friction, providing a reliable and steady drive. This friction-based transfer allows for some slip, which can be advantageous in applications where shock-loading or variable load conditions are present. Sheaves are also relatively easy to install and maintain and are available in a vast array of configurations, often making them the most cost-effective option.

Customizing Pulleys for Optimal Performance

Engineers tailor custom pulleys, whether sprockets or sheaves, to meet the specific requirements of an application. This customization process involves selecting the appropriate material, design, and dimensions to ensure optimal performance. For instance, in environments with high wear and tear, a pulley made from high-strength steel or aluminum might be chosen. In contrast, for applications where weight is a critical factor, lighter materials such as composites or specialized alloys may be used.

Key Factors in Pulley Customization

- Material Selection: Choosing the right material based on factors such as strength, weight, wear resistance, and cost.

- Design Specifications: Determining the number of teeth for sprockets or the groove dimensions for sheaves to match the belt or chain.

- Application Requirements: Considering the operational environment, including load conditions, speed, and the need for precision.

Advantages of Custom Pulleys

Custom pulleys offer numerous advantages, including:

- Enhanced Performance: By tailoring the design and material, custom pulleys ensure efficient power transmission and longevity.

- Reduced Downtime: Precisely fitted pulleys reduce the risk of mechanical failure and the need for frequent maintenance.

- Versatility: Engineers can design custom pulleys to fit a wide range of applications, from high-tech machinery to heavy industrial equipment.

Maintenance and Care of Pulleys

Proper maintenance and care are essential to maximize the lifespan and efficiency of pulleys. Regular inspection for wear and tear, ensuring correct tensioning of belts or chains, and timely replacement of worn components are critical practices.

Maintenance Tips

- Regular Inspection: Check for signs of wear, such as cracks, grooves, or uneven wear patterns.

- Correct Tensioning: Properly tension belts and chains to prevent slippage and undue stress on the pulley.

- Lubrication: Apply appropriate lubrication to reduce friction and wear.

Pulleys, whether sprockets or sheaves, play a vital role in numerous applications, providing efficient and reliable power transmission. Custom pulleys, designed to meet specific requirements, enhance the performance and longevity of mechanical systems. By understanding the various types of pulleys, their applications, and the benefits they offer, one can make informed decisions to optimize their use in any given system. Proper maintenance further ensures that these critical components continue to operate effectively, contributing to the overall efficiency and productivity of the machinery they support.

CONTINUE READING

Related Posts

In mechanical drives, gears are essential for transmitting motion, power, and torque across various applications. Two of the most commonly […]

In the world of industrial machinery, efficiency, precision, and reliability are essential. A key component in achieving these goals is […]

In the world of industrial engineering, precision and innovation are essential to staying competitive and meeting the ever-growing demands of […]