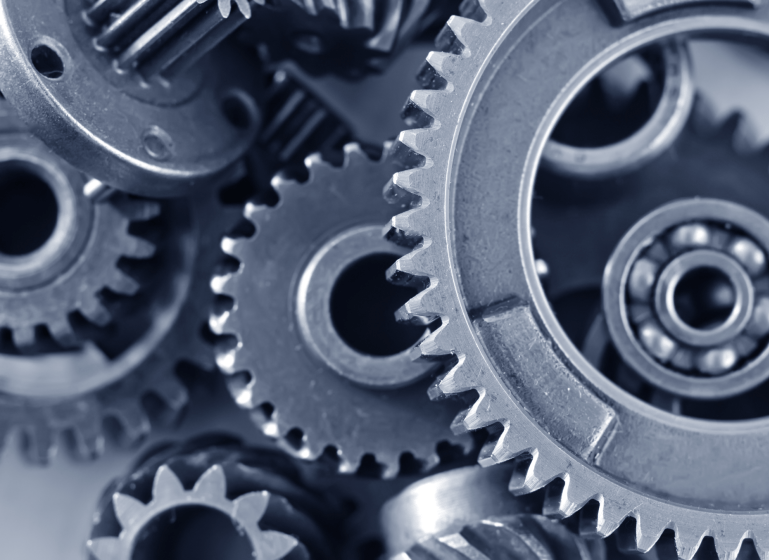

Precision gears are a crucial component in various industrial applications, transmitting power and motion between mechanical components. The industrial sprocket is a specific type of precision gear. It plays a significant role in various industries, facilitating operations in transportation, manufacturing, and energy production alike.

The Importance of Industrial Sprockets

Industrial sprockets are essential components of industrial machinery and systems. They serve as driving elements in chains, belts, and gear trains, ensuring efficient power transmission and motion control. Typically, situations demanding precise synchronization and timing involve the use of sprockets. They find application in bicycle chains, automotive engines, timing belts, and agricultural machinery.

Functionality of Industrial Sprockets

Industrial sprockets undergo engineering to withstand high stress levels and efficiently transfer torque. They prioritize accurate chain synchronization and timing. Commonly crafted from robust materials like steel or titanium alloys, these sprockets feature precisely cut teeth with exacting tolerances, ensuring seamless engagement with mating chains or belts. The sprockets’ load-bearing capabilities and strength are crucial for ensuring reliable power transmission and preventing premature wear or failure.

Precision Manufacturing Processes

The production of industrial sprockets requires precision manufacturing techniques to ensure accurate dimensions, smooth surfaces, and consistent quality. The manufacturing process for sprockets comprises several stages. It includes material selection and heating, precision cutting of teeth, surface finishing, and quality control testing.

Material selection stands as a critical step in the manufacturing process. It defines the physical properties and performance characteristics of the sprocket. High-strength steels and titanium alloys are commonly used for their ability to withstand high stress and wear.

“Heating and forming” refers to the process of subjecting the raw material to high temperatures. This softens the material, enabling it to be shaped into the desired sprocket geometry. This process involves initially heating the material to an exact temperature. Subsequently, the heated material is shaped into the desired form using dies or other forming tools.

Precision-cutting the teeth involves employing advanced machining techniques like milling or grinding to precisely shape the teeth into the sprocket body. This step requires precision tools and strict attention to detail to ensure accurate tooth dimensions and smooth tooth surfaces.

Surface finishing involves polishing or coating the sprocket surface to enhance its appearance, reduce friction, and improve wear resistance. This step may involve tumbling, sanding, or coating with lubricants or polymers to achieve the desired surface finish and performance characteristics.

Quality control testing is an essential step in the manufacturing process to ensure the sprockets meet the required specifications and performance standards. This testing may involve dimensional measurements using precision gauges or scanning electron microscopes (SEM), tensile testing to determine material strength, fatigue testing to assess durability under cyclic loading conditions, and functional testing to validate power transmission performance.

Engineering Mastery in Action

The engineering mastery behind the design and production of industrial sprockets is reflected in their precision manufacturing processes, material selection, and attention to detail. The use of advanced machining techniques, high-strength materials, and surface finishing methods enable the production of sprockets that are reliable, durable, and efficient in various industrial applications.

By understanding the importance, functionality, and precision manufacturing processes of industrial sprockets, engineers can better appreciate the engineering mastery that goes into their design and production. This knowledge can inform decision-making in material selection, process optimization, and quality control to ensure the production of high-performance sprockets for various industrial applications.

More: Adapting to Farming Challenges: The Versatility of Custom Agricultural Machinery Sprockets

CONTINUE READING

Related Posts

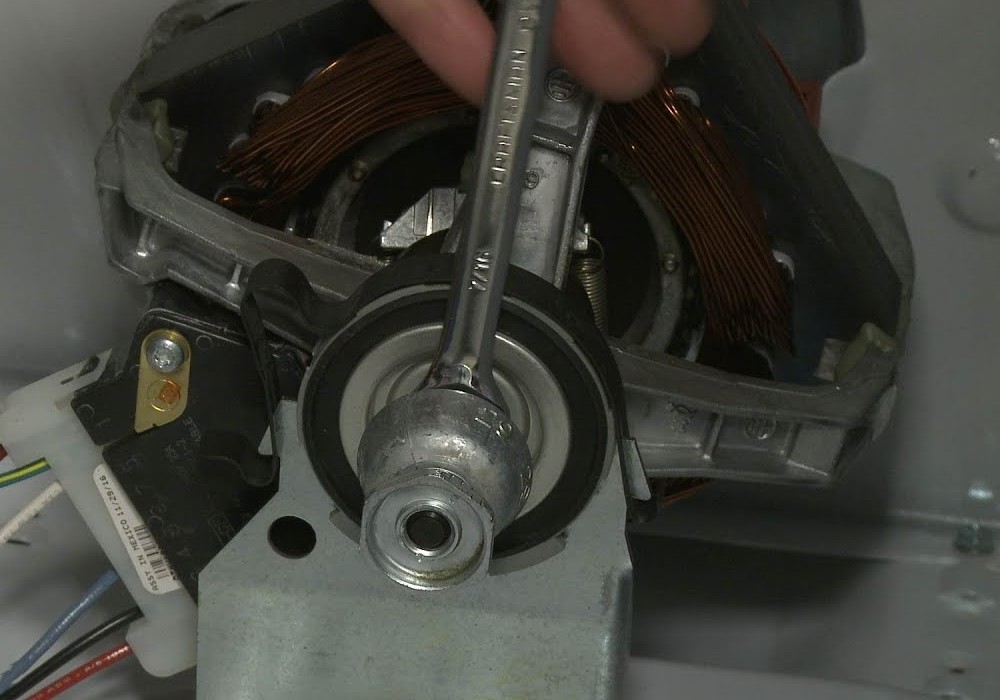

A motor pulley is a component used in belt-driven systems that helps transmit power from an electric motor to a […]

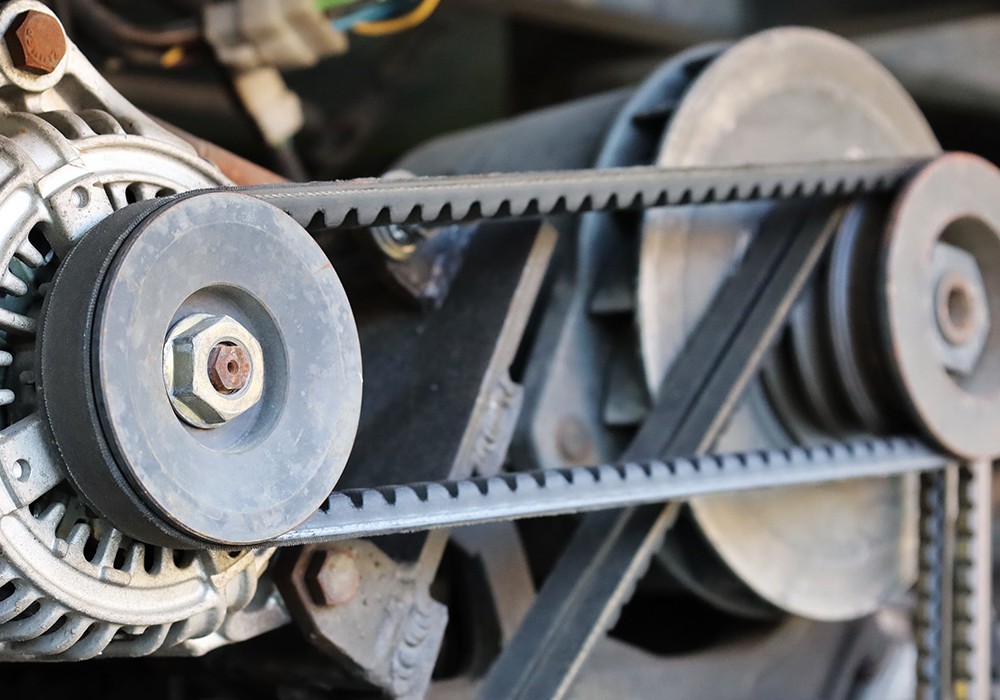

A bad engine pulley can make different types of noises such as a whining noise, screeching noise, squeaking noise, or […]

Motor belts and pulleys are components used in power transmission systems to transfer power from a motor to other rotating […]