In industrial settings, a smooth and quiet power transmission system is crucial for productivity, safety, and worker comfort. V Belt Pulleys, known for their efficiency and reliability, address the issue of noisy power transmission, making them an essential component across various industries. These pulleys offer numerous benefits, earning them the reputation of “smooth operators” in power transmission systems.

What Are V Belt Pulleys?

V Belt Pulleys are mechanical components designed to transfer rotational power between shafts using V-belts. These pulleys feature a V-shaped groove that ensures a secure grip on the belt, facilitating smooth and efficient power transmission. Unlike traditional chain drives, V Belt Pulleys operate quietly and reduce the risk of slippage, making them highly suitable for applications that require a quiet and efficient working environment. V Belt Pulleys are widely used across industries like manufacturing, agriculture, and automotive, playing a crucial role in power transmission systems.

Key Benefits of V Belt Pulleys

1. Noise Reduction

The primary benefit of V Belt Pulleys is their ability to reduce operational noise. In environments such as factories, workshops, and even in domestic applications, excessive noise can be disruptive. V Belt Pulleys minimize noise pollution by ensuring that the belt engages smoothly with the pulley, avoiding the clatter and vibration typically associated with other types of power transmission systems like chain drives.

2. Smooth Power Transmission

V Belt Pulleys deliver smooth and consistent power transfer, reducing the risk of wear and tear on machinery components. By ensuring that power is transmitted with minimal disruption, these pulleys help extend the lifespan of the machinery and reduce the frequency of maintenance, which ultimately saves on operational costs.

3. Efficiency

V Belt Pulleys are engineered for maximum efficiency. With reduced slippage and improved contact between the belt and pulley, they ensure that the power generated is utilized effectively, leading to better performance. This translates into higher productivity in industrial operations.

4. Versatility

Available in a variety of sizes, materials, and configurations, V Belt Pulleys are suitable for a wide range of applications. Whether it’s for a small-scale conveyor system or large industrial equipment, V Belt Pulleys offer the versatility needed to meet the demands of different sectors.

Frequently Asked Questions

Are V Belt Pulleys compatible with all types of machinery?

Yes, V Belt Pulleys are compatible with various machinery types. However, it’s important to ensure that the pulley size, material, and load capacity match the requirements of your specific system.

Do V Belt Pulleys require special maintenance?

While V Belt Pulleys are relatively low-maintenance, they do benefit from regular inspections. Proper lubrication, tension adjustments, and timely replacements of worn belts help ensure optimal performance.

Can V Belt Pulleys withstand heavy loads?

Yes, V Belt Pulleys are designed to handle heavy loads, but it’s crucial to select the appropriate pulley size and material based on the specific requirements of the application.

Selection and Maintenance of V Belt Pulley Systems

Selecting the right V Belt Pulley is key to maximizing its benefits. When choosing a pulley, consider factors such as the type of belt used, the load capacity, and the pulley size. Proper maintenance, including belt tension adjustments, lubrication, and periodic inspections, will help keep your V Belt Pulley system running smoothly and efficiently.

V Belt Pulley Comparison Table

The following table highlights the key features of different types of V Belt Pulleys, helping you select the ideal pulley for your application:

| Pulley Type | Suitable Applications | Advantages | Disadvantages |

| Standard V Belt Pulley | General industrial use, small machinery, conveyors | Reliable, cost-effective, reduces noise | May wear faster under high loads |

| Double Groove V Pulley | Applications requiring multiple belts, heavy-duty systems | Provides better power distribution | More complex installation and alignment |

| Variable Speed Pulley | Conveyor systems, fans, pumps | Allows for adjustable speed control | Higher cost, requires regular maintenance |

| Tapered V Belt Pulley | High torque applications, automotive, construction | High load capacity, durable | Requires precise installation |

| Adjustable V Belt Pulley | Variable speed machinery | Flexibility in adjusting speed ratios | Not as efficient at high speeds |

V Belt Pulleys are a cornerstone of efficient and quiet power transmission systems across various industries. Their ability to reduce noise, enhance efficiency, and provide reliable service makes them an essential component for modern machinery. With the right selection and proper maintenance, businesses can ensure long-lasting, high-performance systems that improve productivity and worker satisfaction.

CONTINUE READING

Related Posts

Machining plays a pivotal role in modern manufacturing, transforming raw materials into precise components essential for various industries. The process […]

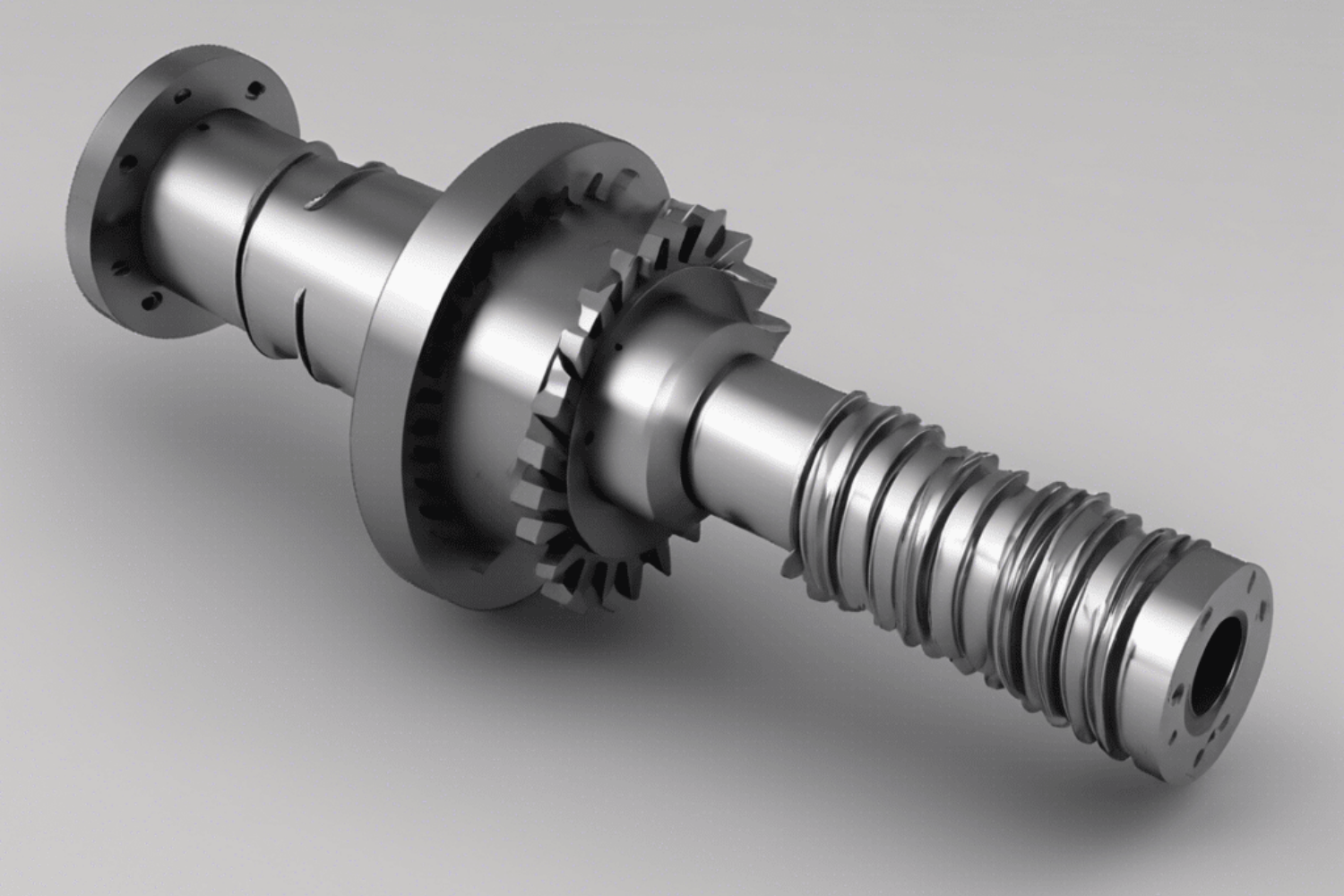

Splined shafts are essential components in various mechanical systems, designed to transmit torque and rotational motion efficiently. Their unique design […]

In the realm of mechanical design and engineering, the choice between custom and standard gear sets is pivotal. This decision […]