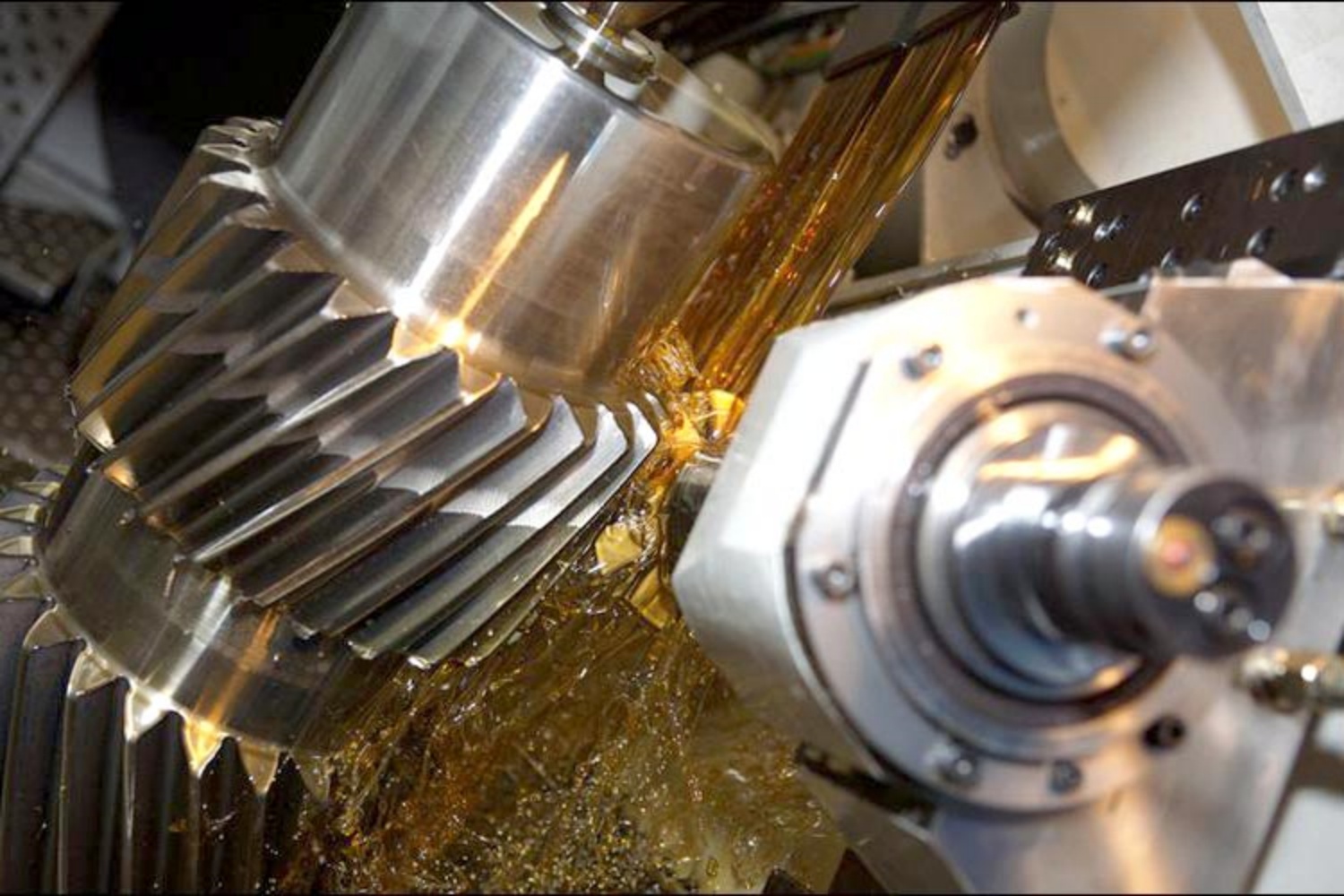

Internal spline spur gears or spur gears are the simplest type of gears, and they are also the easiest visualized common gears that transmit motion between two parallel axes. Generally speaking, when two internal spline spur gears mesh, “gear” refers to the part with more teeth and “pinion” is the part with less teeth.

Internal spline spur gears are used to transmit power from one part of the machine to another. Any number of gears can be connected together with different shapes and sizes. With the following several important functions, gears are used in a large number of mechanical devices.

They can provide reduction or increasing of the gear speed for motorized equipment.

They can increase strength. Generally, small motors that spin very fast can provide enough power to the device, but not enough torque. The output speed can be reduced while increasing the torque through speed reduction of the gears.

They can change direction. When two gears mesh together, the second gear always turns in the opposite direction. The power of the machine with a different angle can be realized by using specially shaped gears. For example, the power of the drive shaft can be turned 90 degrees with the beveled bevel gears in differential.

CONTINUE READING

Related Posts

V-pulley production is a crucial aspect of the power transmission industry, where reliability and durability are paramount. A well-made V-pulley […]

In today’s world, sustainability has become a key factor in manufacturing practices, with companies increasingly realizing the need to operate […]

Spline gears are an essential component of many industrial and mechanical systems, playing a crucial role in power transmission and […]