The pulley and shaft assembly is an essential component of many mechanical systems. It helps to transfer power from the motor to other machinery and equipment, making it possible to run various industrial and commercial operations. One key element of the assembly is the pulley or drive pulley, which is used to transmit power from the motor to the load. However, the performance of the assembly also depends on other components such as bearings, couplings, and shafts. This article will discuss the pull and shaft assembly in detail, including its components, functions, and maintenance.

Components of the Pull and Shaft Assembly

The pull and shaft assembly consists of various components, including the following:

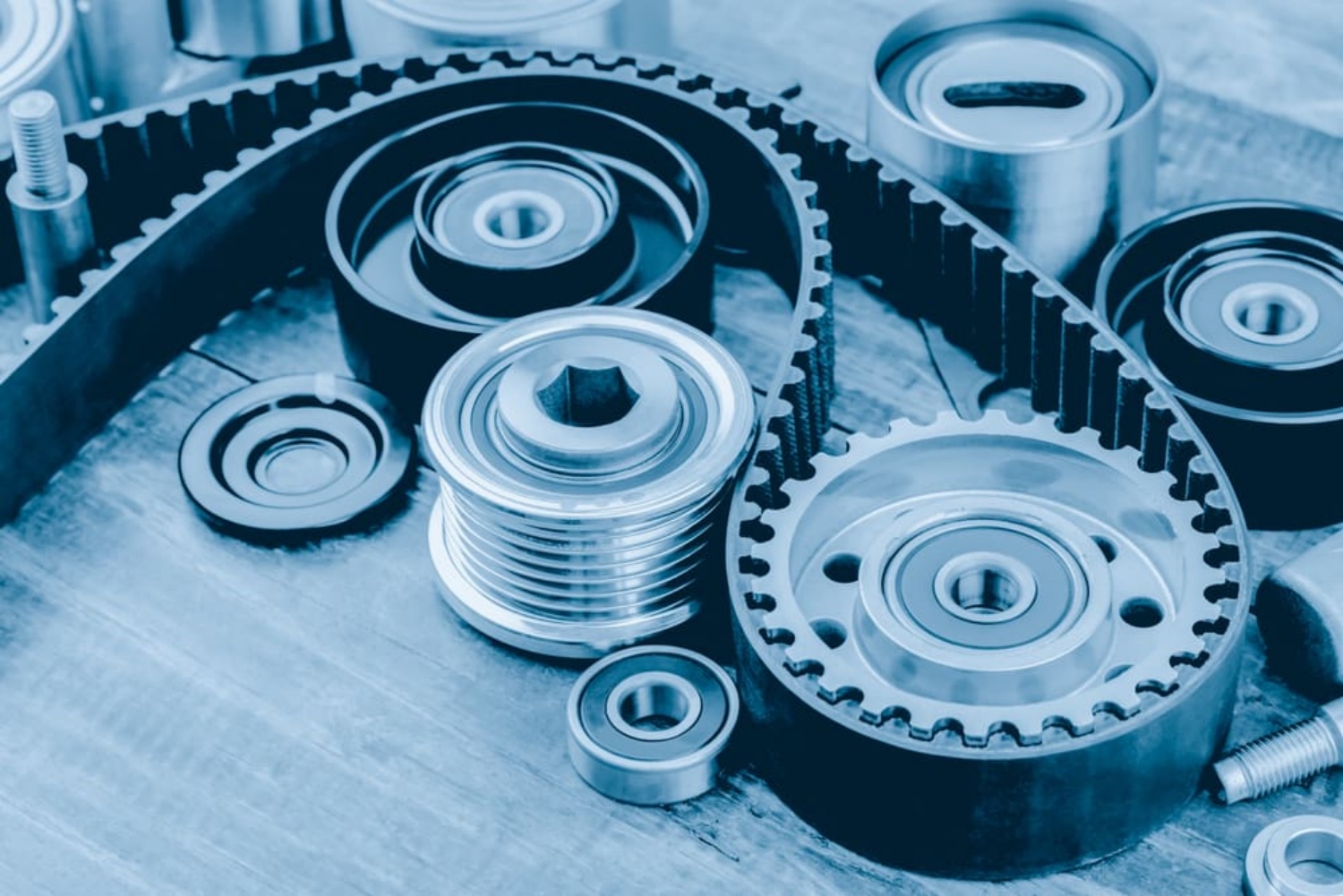

Pulleys: Pulleys are cylindrical components used to transfer power from the motor to the load. They are usually made of metal, such as cast iron or aluminum, and come in different shapes and sizes. Some pulleys have a groove or channel to hold the belt, while others have teeth to grip the belt.

Belts: Belts are flexible, looped components that transfer power from the pulley to the load. They can be made of various materials, including rubber, synthetic polymers, or leather. The type of belt used depends on the application and the load requirements.

Bearings: Bearings are components that support the shaft and pulley assembly. They help to reduce friction and ensure smooth operation. There are different types of bearings, including ball bearings, roller bearings, and sleeve bearings.

Shaft: The shaft is a long, cylindrical component that connects the pulley to the motor. It provides support and stability to the assembly and ensures proper alignment of the pulley and the load.

Couplings: Couplings are mechanical components used to connect two shafts together. They help to transmit torque from one shaft to another and compensate for any misalignment or vibration.

Functions of the Pull and Shaft Assembly

The pull and shaft assembly has several functions, including the following:

Power transmission: The primary function of the assembly is to transfer power from the motor to the load. This is achieved through the pulleys and belts, which connect the motor to the load.

Speed reduction or amplification: Pulleys can be used to increase or decrease the speed of the load. This is achieved by varying the diameter of the pulleys or changing the number of teeth on the pulleys.

Torque multiplication: The assembly can also be used to increase the torque output of the motor. This is achieved by using a larger pulley on the motor and a smaller pulley on the load.

Load management: The assembly helps to manage the load on the motor by transferring the load to the load-bearing components, such as bearings and shafts.

Maintenance of the Pull and Shaft Assembly

Proper maintenance of the pull and shaft assembly is essential for its efficient operation and longevity. Here are some maintenance tips to keep in mind:

Lubrication: Bearings and shafts require regular lubrication to reduce friction and prevent wear. The type and frequency of lubrication depend on the application and the load requirements.

Belt tension: The belt tension should be checked regularly to ensure proper power transmission. A loose belt can slip, causing power loss and reducing efficiency.

Alignment: Proper alignment of the pulleys and shafts is critical for the efficient operation of the assembly. Misalignment can cause vibration, noise, and premature wear of the components.

Inspection: Regular inspection of the components is necessary to identify any signs of wear or damage. Bearings, pulleys, and belts should be checked for cracks, wear, or deformation.

Conclusion

The pull and shaft assembly is a critical component of many mechanical systems. It plays a vital role in power transmission, load management, and torque

CONTINUE READING

Related Posts

In the realm of mechanical engineering and design, the terms “pulley” and “sheave” often surface, leading to a mix of […]

In the realm of industrial automation, the significance of gears and pulleys within the machinery cannot be overstated. These components […]

Industrial gears play a pivotal role in the operational efficiency and productivity of various industries. These components, often housed within […]