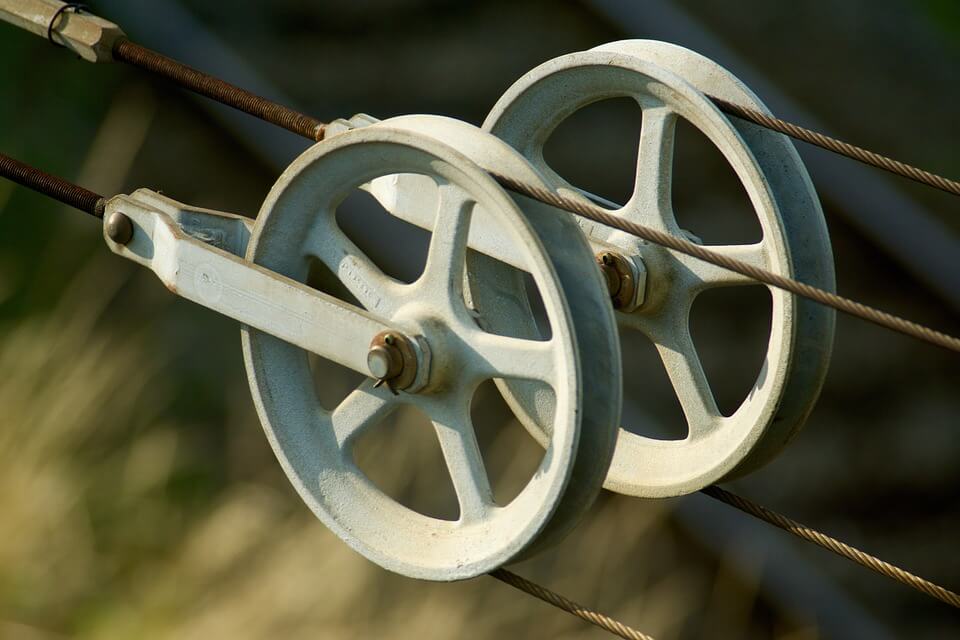

Pulleys are integral components in various mechanical systems, facilitating the smooth transfer of power and motion. However, the lifespan of a pulley can be influenced by several factors that impact its performance and durability. By understanding these key reasons, one can take proactive measures to maximize the lifespan of pulleys and ensure optimal system efficiency. In this article, we will explore the primary factors that affect the life of pulleys and discuss essential considerations for maintenance and longevity.

- Material Selection: The choice of material plays a crucial role in determining the lifespan of a pulley. Different materials possess varying degrees of strength, wear resistance, and corrosion resistance. For example, materials like cast iron and steel are known for their durability and ability to handle heavy loads. Stainless steel pulleys offer excellent corrosion resistance, making them suitable for environments with high humidity or chemical exposure. It is essential to select a material that matches the specific operating conditions and load requirements to ensure long-lasting performance.

- Proper Lubrication: Lubrication is vital for reducing friction and wear in pulley systems. Insufficient or improper lubrication can lead to increased friction, heat generation, and premature wear of pulley components such as bearings and shafts. Regular lubrication with the correct type and amount of lubricant is necessary to maintain smooth operation and prevent excessive wear. It is important to follow manufacturer recommendations and consider factors such as operating speed, temperature, and environmental conditions when determining the lubrication requirements.

- Alignment and Tension: Proper alignment and tension of the belt on the pulley are crucial for optimal performance and longevity. Misalignment can lead to uneven loading, increased wear, and belt slippage, causing premature failure of both the pulley and the belt. Similarly, incorrect tension can lead to excessive stress on the pulley and belt, resulting in reduced lifespan. Regular inspection and adjustment of pulley alignment and belt tension are essential to maintain proper functioning and extend the life of the pulley system.

- Environmental Factors: The operating environment significantly impacts the lifespan of pulleys. Factors such as temperature fluctuations, humidity, dust, and chemical exposure can accelerate wear and corrosion. High temperatures can cause thermal expansion, while moisture and corrosive substances can lead to rust and degradation. Dust and debris can accumulate on pulley surfaces, causing abrasion and reduced performance. Minimizing exposure to extreme temperatures, implementing proper ventilation and sealing measures, and protecting pulleys from dust and chemical exposure can help mitigate these environmental factors and extend the life of the pulley.

- Maintenance and Inspection: Regular maintenance and inspection are critical for identifying potential issues and addressing them promptly. Scheduled maintenance activities, such as cleaning, lubrication, and belt replacement, can help prevent premature wear and failure. Regular inspection allows for the detection of wear, misalignment, or damage to pulley components. Timely repairs or replacements can prevent further damage and extend the overall lifespan of the pulley system.

Conclusion: Several factors influence the lifespan of pulleys, including material selection, proper lubrication, alignment and tension, environmental conditions, and regular maintenance. By understanding and addressing these key reasons, one can optimize the performance, durability, and efficiency of pulley systems. Choosing the right materials, implementing proper lubrication practices, ensuring proper alignment and tension, protecting against environmental factors, and conducting regular maintenance and inspections are crucial steps in maximizing the life of pulleys. By prioritizing these factors, industries can enhance the reliability and longevity of their pulley systems, leading to improved overall system performance.

CONTINUE READING

Related Posts

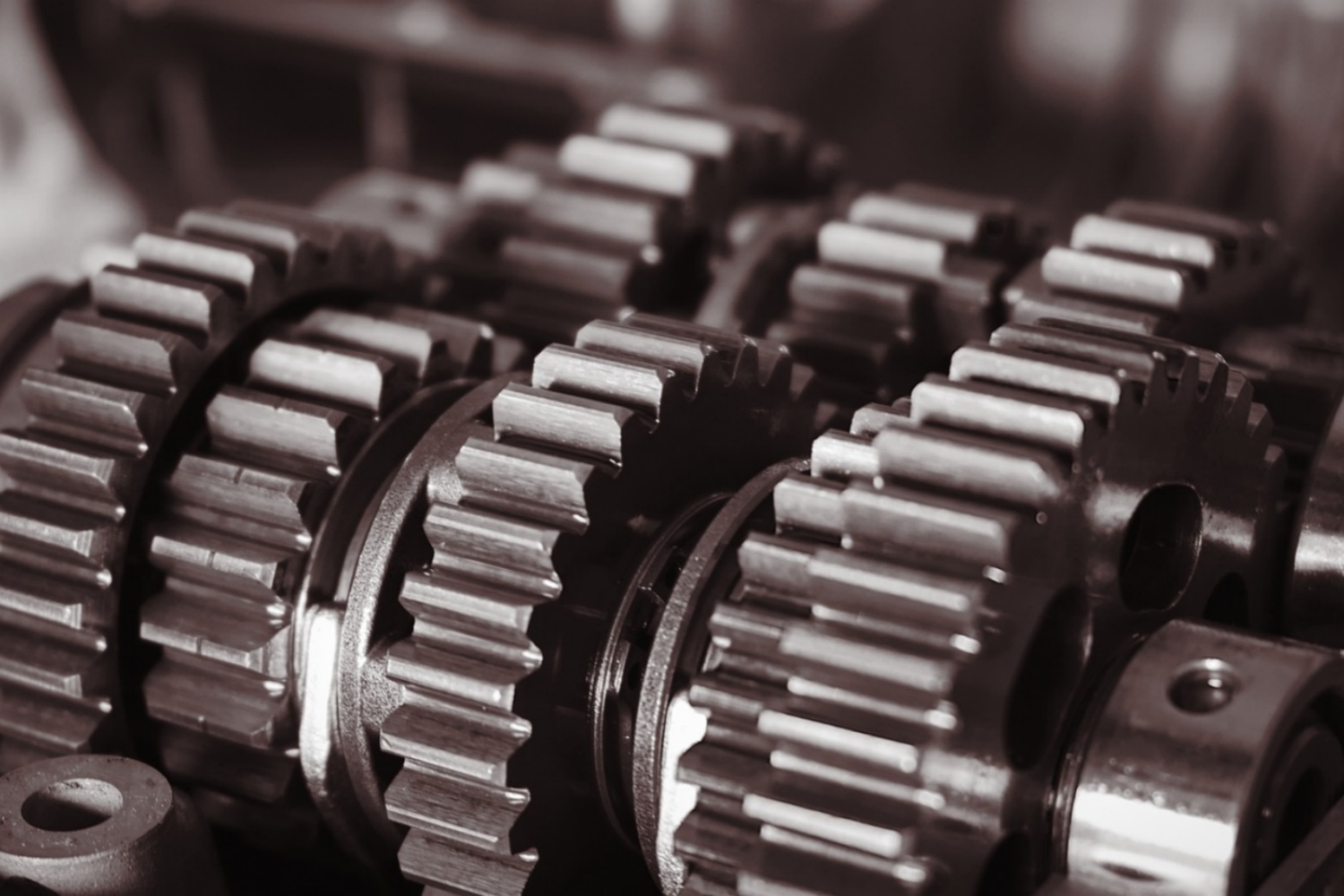

Agricultural gear engineering is a critical aspect of today’s agricultural industry. As the demand for high-performance farm equipment increases, the […]

In today’s industrialized world, the role of sprockets goes beyond their functional significance. They are not just simple components of […]

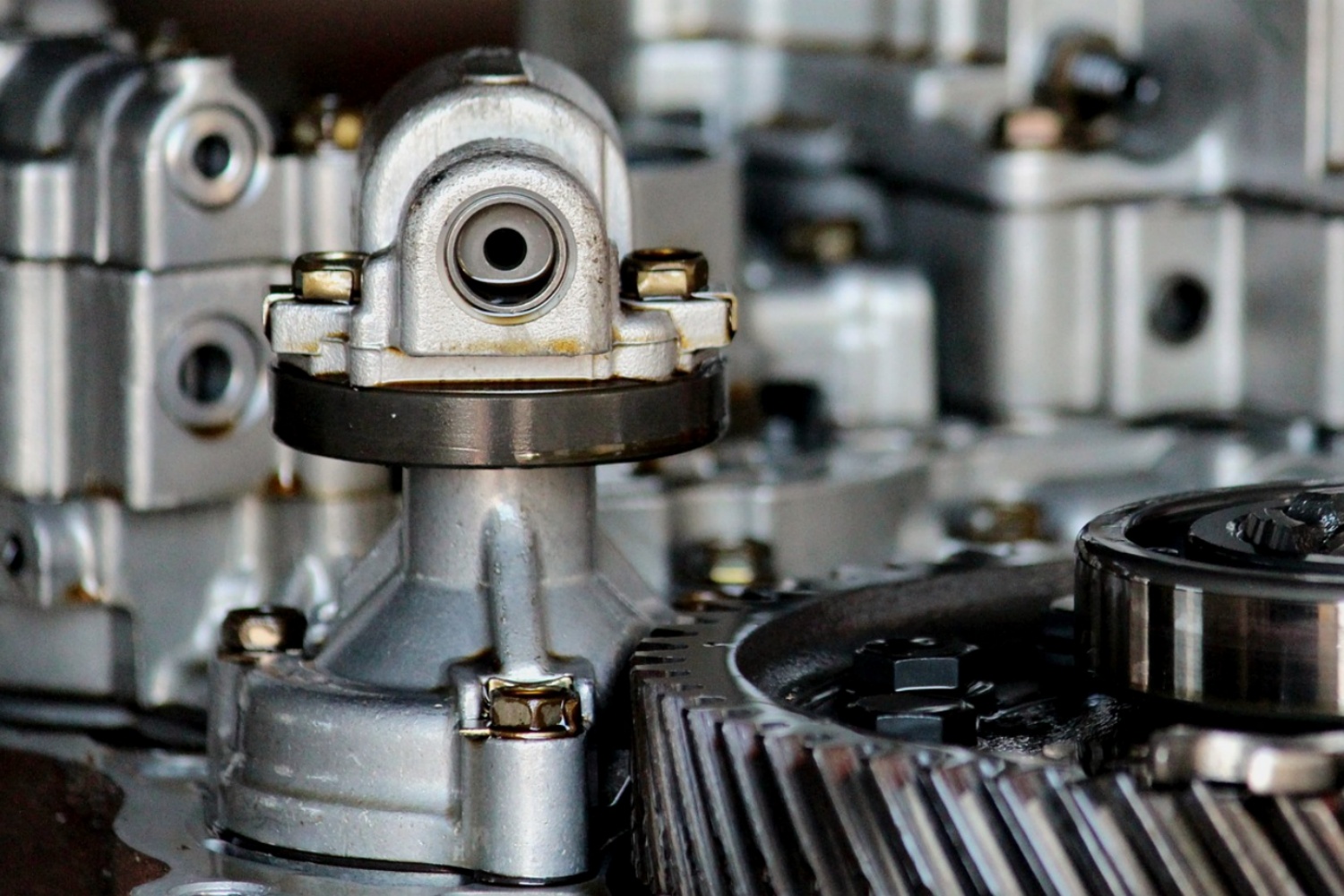

In the intricate web of industrial production, every component plays a crucial role, ensuring the smooth flow of work and […]